Preparation method for extracellular matrix (ECM) composite biological patch

A biological patch and extramatrix technology, applied in medical science, prosthesis, etc., can solve the problems of limited increase in tensile strength of products, serious loss of biological materials, and economic impact, and achieve material saving and great economic benefits. , good uniformity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Preparation of SIS or UBM: SIS or UBM material is obtained after mechanical treatment of pig small intestine or bladder, and SIS or UBM is obtained after disinfection and cleaning with oxyacetic acid + ethanol.

[0032] A. Cut the SIS longitudinally along the intestine, and cut the SIS into SIS units with a longitudinal length of 5-30cm along the transverse direction;

[0033] B. UBM does not need to be cut, and goes directly to the next step (the rest of the methods are the same as SIS).

[0034] (2) Production of vacuum lamination device: connect a vacuum pump with a rubber tube to one end of a pair of nozzle suction filter bottles, and place the suction filter bottles in a foam box with dry ice for use.

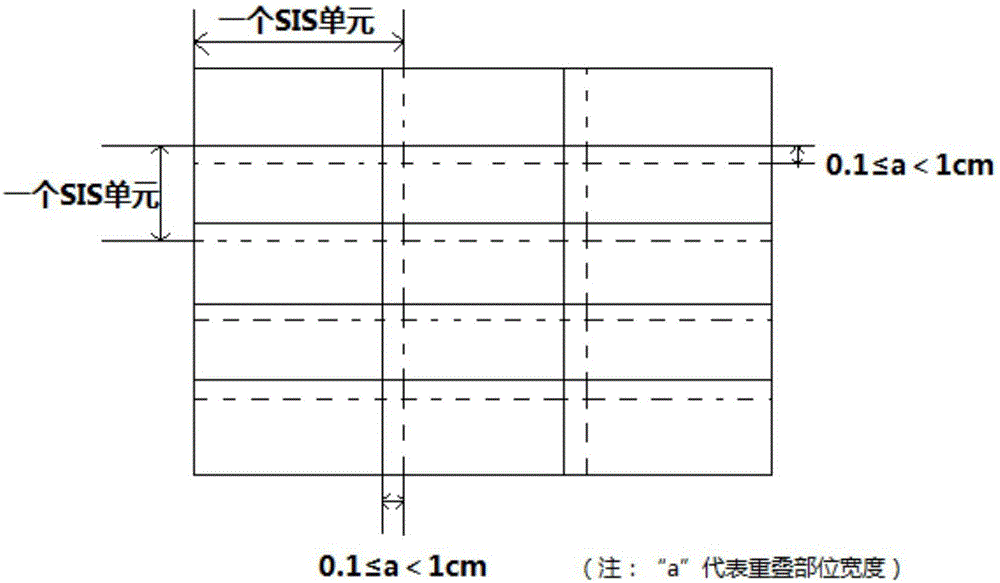

[0035] (3) Take an A4 paper size (30*21cm) phenolic plastic material flat plate evenly distributed with many through holes (patterns are square, diamond, circle, etc.)] and lay it on the table, and lay a layer of medical sand on the flat plate Cloth or not, lay...

Embodiment 2

[0043] Prepare the semi-finished product in (9) according to the method of Example 1, freeze-dry it with a freeze-drying machine (-50° C., under the condition of vacuum 50 μbar, freeze-drying for 16 hours), after freeze-drying, the intermediate product after freeze-drying is lyophilized by means of a seam tenacity machine. Suture with absorbable thread.

Embodiment 3

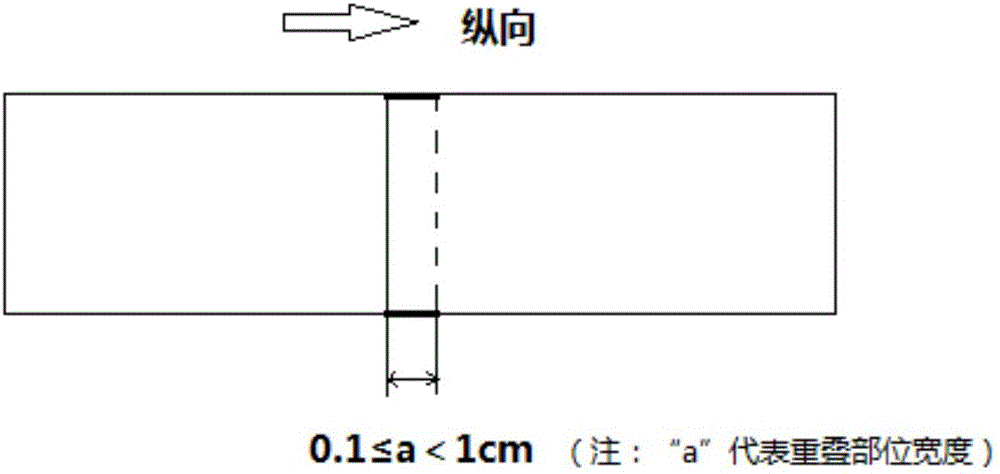

[0045] Take an A4 paper size phenolic plastic board, use SIS to prepare a composite biological patch according to the method of Example 1, wherein the A layer and the B layer are a total of 6 layers (the length of the overlapping part is 0.8cm), and after lamination, it is placed in a freeze dryer (-50 ℃, under the condition of vacuum 50μbar, freeze-dried for 16 hours) to obtain the finished SIS biological patch. (The tensile strength measured with a tensile tester was 52N).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com