Inflating making process and apparatus of spiral wound steel wire reinforced composite plastic pipe

A plastic pipe, reinforced composite technology, applied in the direction of pipes, rigid pipes, pipes/pipe joints/pipe fittings, etc., can solve the problems of peeling and delamination, large changes in shape and size, and reduce the bearing pressure and service life of pipes. Guarantee The effect of uniform distribution and fixed position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

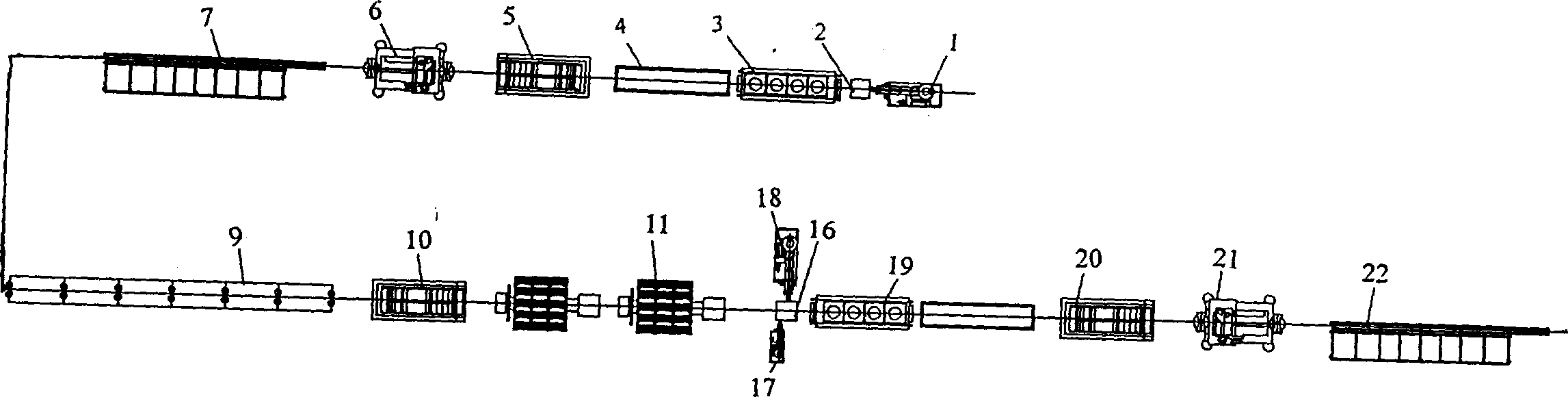

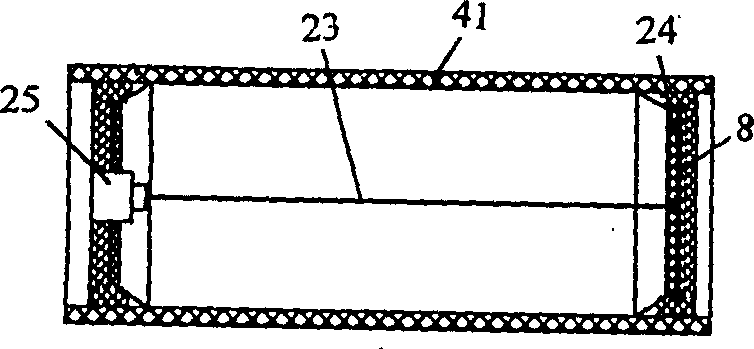

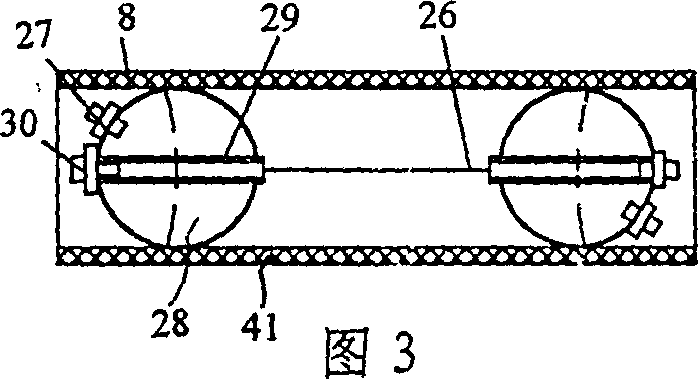

[0055] Figure 1 to Figure 17 The device for manufacturing helically wound steel wire-reinforced composite plastic pipes by air inflation according to Example 1 of the present invention is given. Including 65 extruder 1, core tube extrusion die 2, vacuum sizing box 3, spray cooling water tank 4, tractor 5, cutting machine 6, tube turning machine 7, core tube inflatable sealing assembly 8 arranged in sequence Core tube plugging inflation workbench 9, core tube pushing machine 10, two spiral winding machines 11, such as Figure 8 The composite die head 16 with heating device of the molding cavity 13 of the binder layer containing the binder flow channel 12 shown and the molding cavity 15 of the outer polymer layer containing the outer tube plastic flow channel 14 are respectively combined with the adhesive The 45 adhesive extruders 17,65 plastic extruders 18 connected by the binder runner 12 and the outer pipe plastic runner 13, the sizing box 19, the tractor 20, the cutting ma...

Embodiment 2

[0074] Figure 18 The device for manufacturing helical steel wire reinforced composite plastic pipes by air inflation according to Example 2 of the present invention is given. The device of present embodiment 2 is basically the same as embodiment 1, and the difference is that there is a 45 extruder 97 to coat the steel wire with adhesive at the rear end of the latter spiral winding machine, and the composite film head 98 is a band heater Outer tube extrusion die. The inflatable core tube is wound with a steel wire reinforcement by the spiral winding machine, and then the extruder 97 is coated with a binder, and then extruded through the outer tube to extrude the composite polymer outer layer of the die head. On the core pipe extrusion die head 99, there is a 45 extruder 100 that cooperates with it.

Embodiment 3

[0076] Fig. 19 is a device for manufacturing spiral steel wire reinforced composite plastic pipes according to Example 3 of the present invention. The device in Embodiment 3 is basically the same as in Embodiment 2. The difference is that there is an extruder 101 at the outlet end of the previous spiral winding machine to coat the steel wire on the core tube with adhesive. Its method is the same with embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com