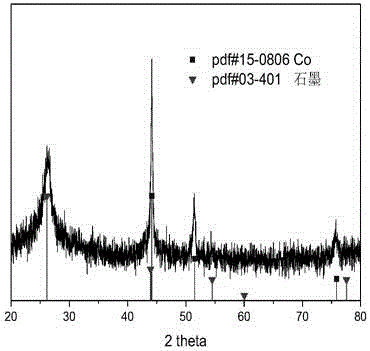

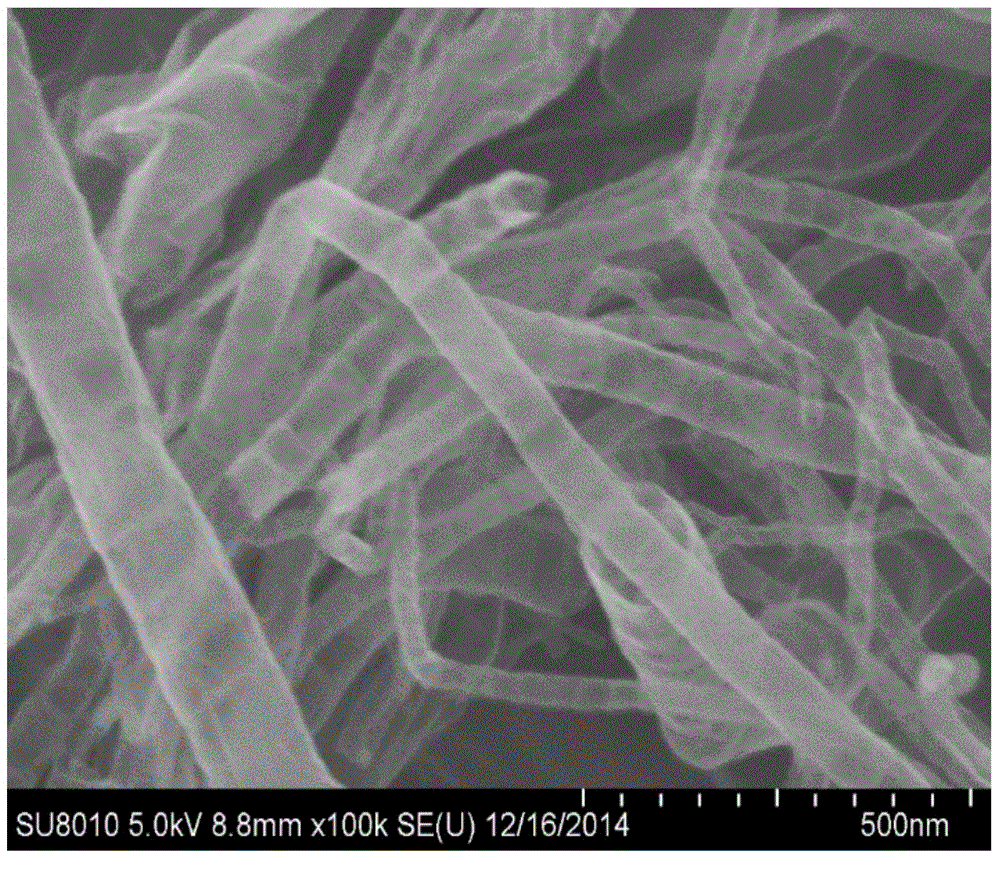

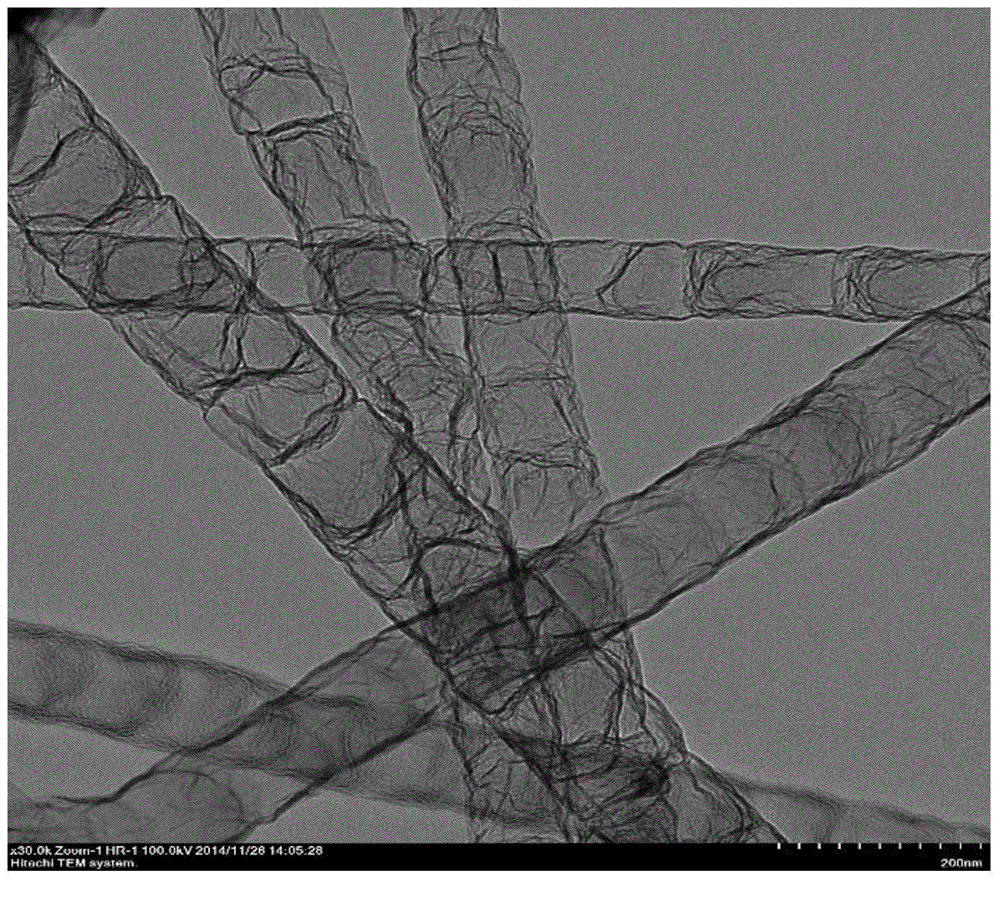

Method for synthesis of cobalt nanoparticle and bamboo-like nitrogen doped carbon nanotube composite material

A technology of nitrogen-doped carbon and composite materials, which is applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., and can solve the problems of uneven diameter of carbon nanotubes, inability to produce in large quantities, and loose compounding. , to achieve the effect of uniform product size and shape, unique product structure and short reaction cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Dissolve cobalt nitrate and melamine respectively in methanol according to the molar ratio of 1:200, stir magnetically for 30 minutes until fully dissolved, then heat and evaporate at 60 degrees, evaporate to dryness, cool to room temperature naturally, and grind to obtain a sample powder.

[0027] (2) The obtained sample powder is put into a tube furnace and fed with nitrogen for calcination, the temperature is raised to 400 degrees at 5 degrees per minute and kept for 1 hour, and then raised to 700 degrees at 10 degrees per minute and kept for 3 hours to obtain a sample product.

[0028] (3) The obtained sample product is treated with 0.5M hydrochloric acid, then washed and centrifuged with deionized water and absolute ethanol, and then dried in a vacuum oven at 80 degrees to obtain cobalt nanoparticles and bamboo-shaped nitrogen-doped carbon nanotube composites.

Embodiment 2

[0030] (1) Dissolve cobalt acetate and dicyandiamine in ethanol at a molar ratio of 1:2, and stir magnetically for 30 minutes until fully dissolved. Then heated and evaporated at 60°C, evaporated to dryness, cooled to room temperature naturally, and ground to obtain sample powder.

[0031] (2) The obtained sample powder is put into a tube furnace and fed with nitrogen for calcination, the temperature is raised to 400 degrees at 5 degrees per minute and kept for 1 hour, and then raised to 700 degrees at 10 degrees per minute and kept for 3 hours to obtain a sample product.

[0032] (3) The obtained sample product is treated with 0.5M sulfuric acid, then washed and centrifuged with deionized water and absolute ethanol, and then dried in a vacuum oven at 80 degrees to obtain cobalt nanoparticles and bamboo-shaped nitrogen-doped carbon nanotube composites.

Embodiment 3

[0034] (1) Dissolve cobalt chloride and cyanamide in deionized water at a molar ratio of 1:10, and stir magnetically for 30 minutes until fully dissolved. Then heated and evaporated at 60°C, evaporated to dryness, cooled to room temperature naturally, and ground to obtain sample powder.

[0035] (2) The obtained sample powder was put into a tube furnace and fed with nitrogen for calcination, and the temperature was raised to 500 degrees at 2 degrees per minute and kept for 3 hours to obtain the sample product.

[0036] (3) The obtained sample product is treated with 0.5M nitric acid, then washed and centrifuged with deionized water and absolute ethanol, and put into a vacuum drying oven at 80 degrees to dry to obtain cobalt nanoparticles and bamboo-shaped nitrogen-doped carbon nanotube composites.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com