A method for preparing ptfe varnished cloth, ptfe varnished cloth and metal foil clad laminate prepared by the method

A PTFE and metal-clad technology, which is applied in the direction of metal layered products, chemical instruments and methods, coatings, etc., can solve the problems affecting production efficiency and limited thickness of resin layer, so as to reduce the number of gluing times, uniform thickness, and improve performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

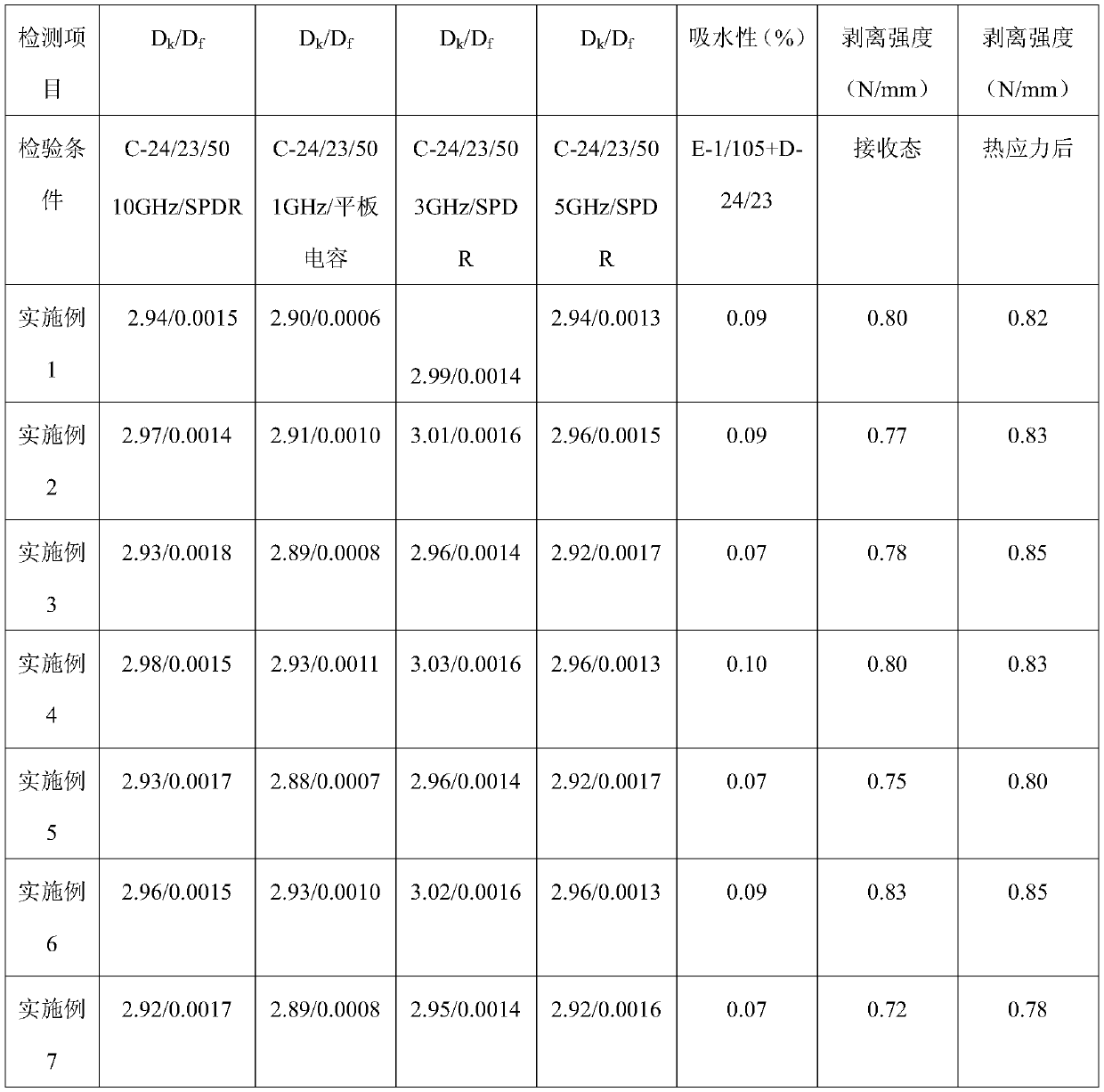

Examples

Embodiment 1

[0040] In the present embodiment, the PTFE paint cloth is prepared by the following method, which specifically includes the following steps:

[0041](1) 1080 glass fiber cloth is dipped in PTFE glue, and then sintered to obtain a dipped glass cloth, the thickness of which is 0.054mm;

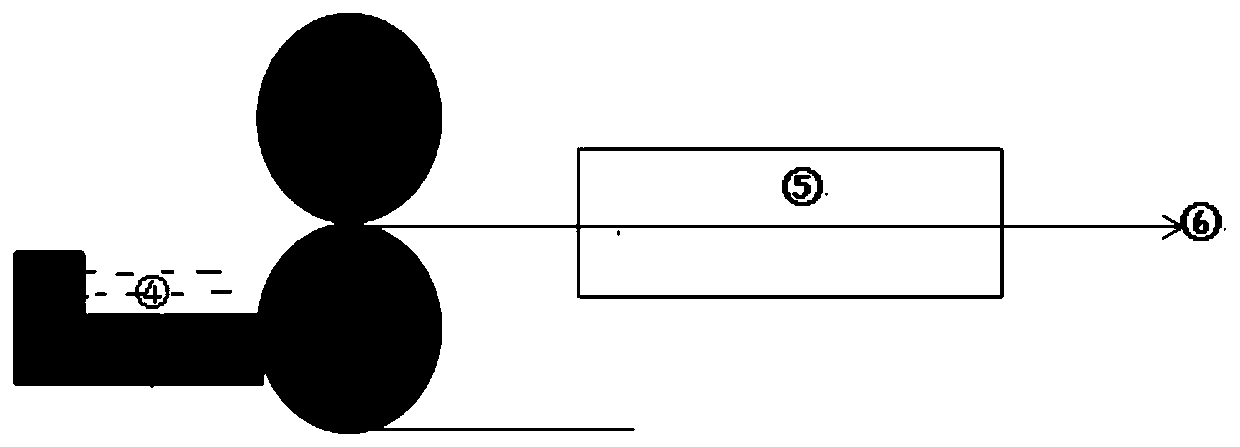

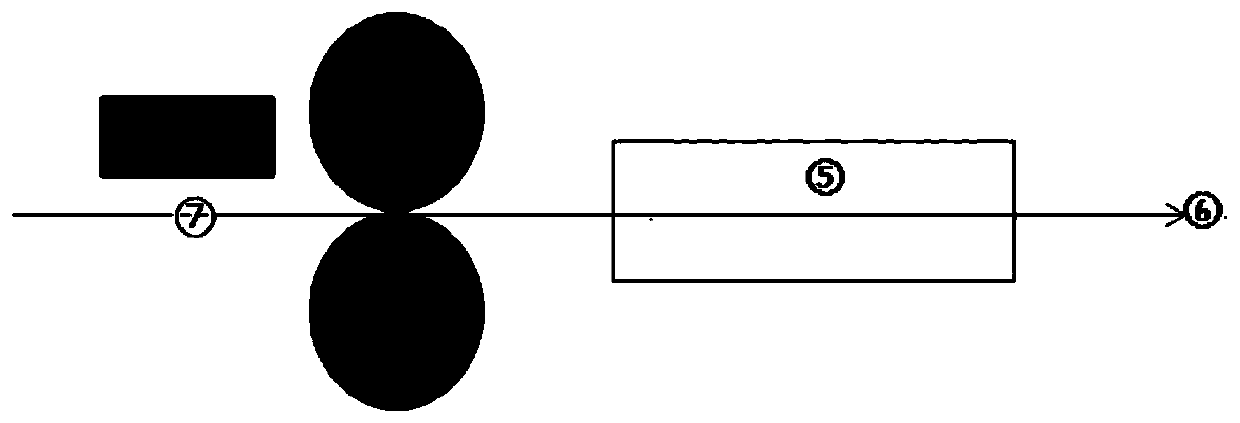

[0042] (2) Use such as figure 1 The horizontal coating machine shown in step (1) is coated with PTFE glue on one side of the primary dipped glass fiber cloth obtained in step (1), and the coating thickness is set to 0.100mm, dried and sintered to obtain a 0.154mm single-sided PTFE Linoleum (including glass fiber cloth);

[0043] (3) Use such as figure 1 The horizontal coating machine shown in the step (2) is coated with PTFE glue solution on the other side of the PTFE paint cloth obtained by step (2), and the coating thickness is set to 0.100mm, dried and sintered to obtain the PTFE paint cloth coated with glue on both sides, and its two sides are coated with The thickness (including glass fi...

Embodiment 2

[0045] In the present embodiment, the PTFE paint cloth is prepared by the following method, which specifically includes the following steps:

[0046] (1) 1080 glass fiber cloth is dipped in PTFE glue, and then sintered to obtain a dipped glass cloth, the thickness of which is 0.054mm;

[0047] (2) Use such as figure 1 The horizontal coating machine shown in step (1) is coated with PTFE glue on one side of the primary dipped glass fiber cloth obtained in step (1), and the coating thickness is set to 0.2mm, dried and sintered to obtain a single-sided PTFE of 0.254mm Linoleum (including glass fiber cloth);

[0048] (3) Use such as figure 1 The horizontal coating machine shown in the step (2) is coated with PTFE glue solution on the other side of the PTFE paint cloth obtained by step (2), and the coating thickness is set to 0.2mm, dried and sintered to obtain the PTFE paint cloth coated with glue on both sides. The thickness (including glass fiber cloth) is 0.454mm in total.

Embodiment 3

[0050] In the present embodiment, the PTFE paint cloth is prepared by the following method, which specifically includes the following steps:

[0051] (1) 1080 glass fiber cloth is dipped in PTFE glue, and then sintered to obtain a dipped glass cloth, the thickness of which is 0.054mm;

[0052] (2) Use such as figure 1 The horizontal coating machine shown in the step (1) is coated with PTFE glue on one side of the primary dipped glass fiber cloth obtained in step (1), the coating thickness is set to 0.05mm, dried and sintered to obtain a 0.0.104mm single PTFE varnished cloth (including glass fiber cloth);

[0053] (3) Use such as figure 1 The horizontal coating machine shown in the step (2) is coated with PTFE glue solution on the other side of the PTFE paint cloth obtained by step (2), and the coating thickness is set to 0.05mm, dried and sintered to obtain the PTFE paint cloth coated with glue on both sides. The thickness (including glass fiber cloth) is 0.154mm in total. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com