Curved glass and preparation method thereof

A technology of curved glass and calcite, applied in glass manufacturing equipment, glass molding, glass re-molding, etc., can solve the problems of inconsistent side height of hot bending, glass can not be formed, glass curved surface indentation, etc., to reduce Lamination marks, good flatness and high forming precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The specific steps of the production method are as follows:

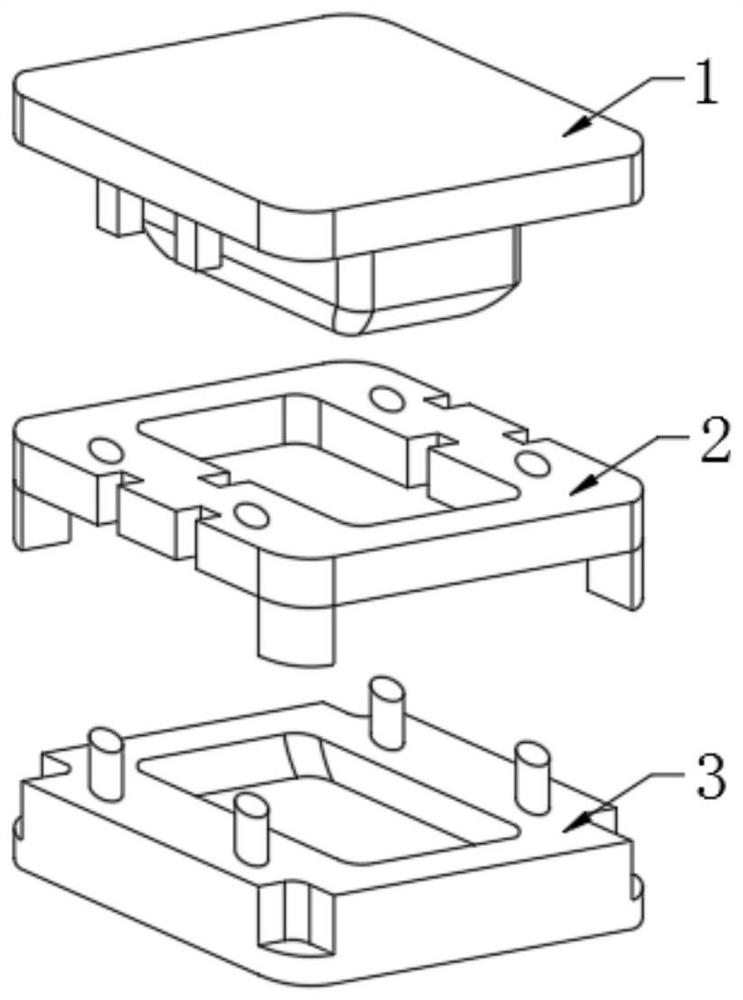

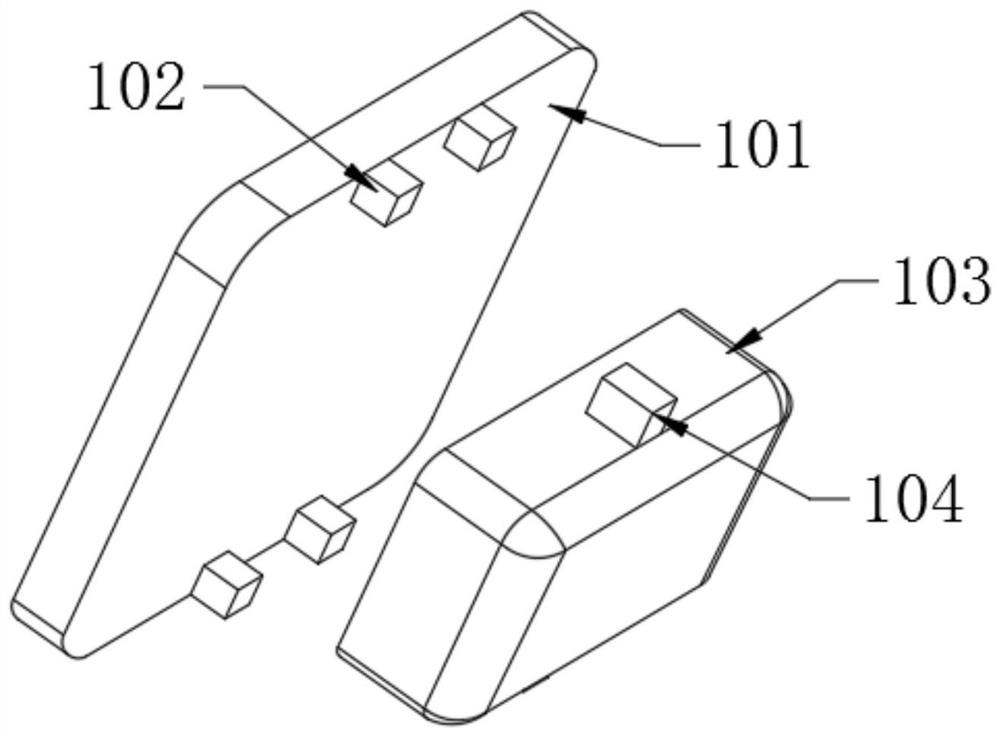

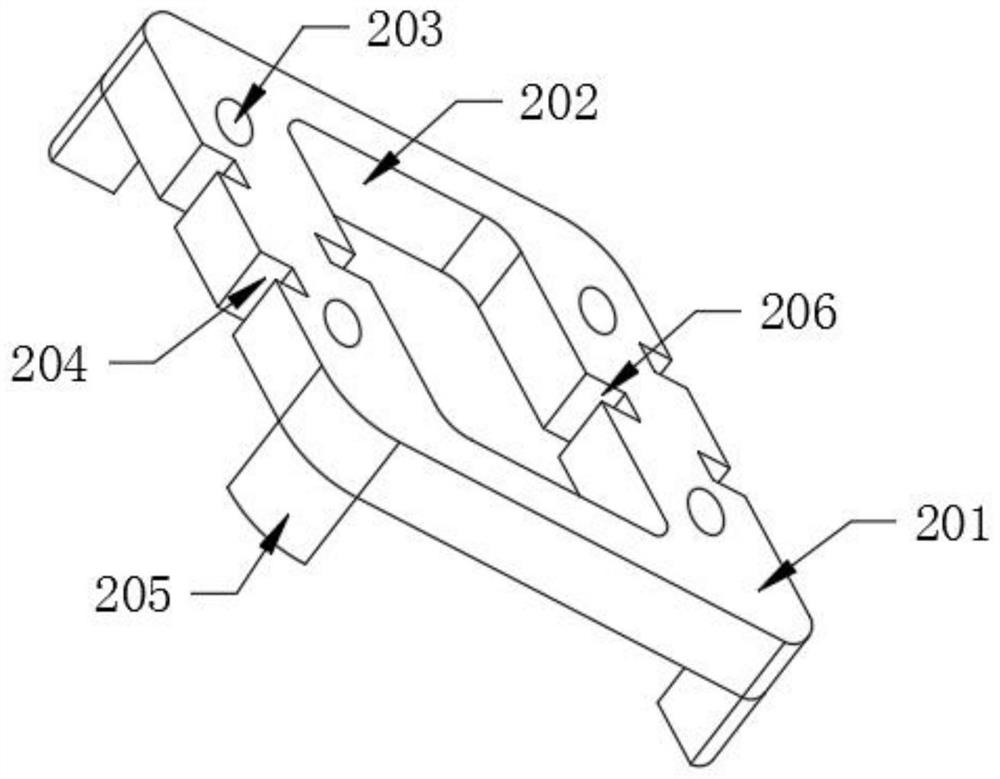

[0035]In the molding stage, the concave positioning module 3 is fixed, and the glass blank is placed in the concave mold groove 302, so that the convex positioning module 1 is in contact with the glass blank; in the preheating stage, the convex positioning module 1, the concave positioning module 3 and the glass The blank plate is preheated, and the temperature of the convex positioning module 1 is less than or equal to the temperature of the concave positioning module 3, and the temperature of the convex positioning module 1 is less than or equal to the glass transition temperature of the glass blank plate, and then the convex positioning module 1 and the concave positioning module 3 Put it into the forming furnace together with the glass blank, heat until the glass is softened, and keep it warm for 35-45 minutes, then vacuumize the hot bending mold, a vacuum is formed in the hot bending mold, and the softene...

Embodiment 2

[0037] The specific steps of the production method are as follows:

[0038] Take out the hot bending mold from the forming furnace, gradually cool down the temperature of the hot bending mold and the glass shell in the hot bending mold until it cools down to room temperature, take out the glass shell to get a curved glass semi-finished product, and roughen the surface of the curved glass semi-finished product; then the curved surface of the semi-finished product Steps for glass to be edged. Specifically, use a CNC edging machine for edging treatment, wherein the CNC edging machine is, for example, Beijing Jingdiao CNC edging machine, and the process parameters for edging treatment are: the feed speed is 400mm / s-800mm / s, the spindle The rotating speed is 15000r / min~35000r / min, the positioning height is 4mm~8mm, and the time for edging treatment is 60s~200s;

Embodiment 3

[0040] The specific steps of the production method are as follows:

[0041] After the curved glass is edged, the curved glass is polished in a polishing solution. The specific steps are: install the curved glass after the edge grinding in the polishing mold, and install the polishing mold on the polishing equipment , attach polishing material on the polishing equipment, add polishing liquid, and perform polishing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com