A kind of glass and preparation method thereof

A glass and formula technology, applied in the field of glass manufacturing, to achieve the effect of improving melting characteristics, good clarification effect, and ensuring food safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0163] Correspondingly, as Figure 6 As shown, the embodiment of the present invention also provides a method for preparing glass, which includes the following steps in sequence:

[0164] S101. Weigh the ingredients according to the main raw material formula of the glass.

[0165] The main raw material formula of the glass includes quartz sand, soda ash, calcite, feldspar, carbon powder and active agent;

[0166] The active agent is mainly composed of

[0167] SiO 2 8~11%

[0168] Active oxidizing agent 12~19%

[0169] al 2 o 3 0.1~3%

[0170] Na 2 O12~16%

[0171] CaO20~28%

[0172] Volatility 30~40%

[0173] Fe 2 o 3 0.01~1%

[0174] composition.

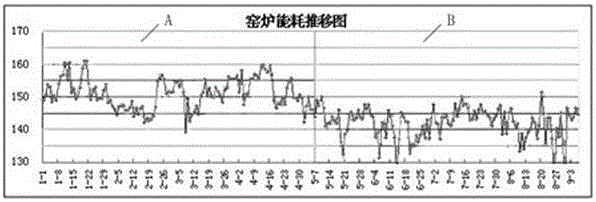

[0175] S102, the ingredients are put into a melting furnace, and melted at a temperature of 1500° C. to 1650° C. to obtain molten glass.

[0176] Preferably, the melting temperature is 1550°C to 1560°C.

[0177] S103, performing molding treatment on the molten glass. Wherein, the forming temperature of the molten...

Embodiment 1

[0184] According to the formula: 420 parts of quartz sand, 110 parts of soda ash, 100 parts of calcite, 50 parts of feldspar, 0.05 parts of carbon powder, 2 parts of active agent, and an appropriate amount of decolorizing agent. The active agent is made of 8% SiO 2 , 12% active oxidant, 3% Al 2 o 3 , 16% Na 2 O, 20% CaO, 40% volatile, 1% Fe 2 o 3 Composition: Put the ingredients into the melting furnace and melt at a temperature of 1500°C to obtain molten glass; shape the molten glass at 1000°C; and anneal the molten glass at 450°C.

Embodiment 2

[0186] Adopt the raw material formula of the glass listed in Example II, weigh the ingredients according to the formula; put the ingredients into the melting furnace, and melt the glass at a temperature of 1550°C to obtain molten glass; shape the molten glass at 1060°C; Annealing at 500°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com