ABS consumable for 3D printing, and preparation method thereof

A technology of 3D printing and consumables, applied in the direction of additive processing, etc., can solve the problems of uneven wire diameter and large shrinkage rate of ABS, and achieve the effect of high gloss, reduce friction and increase melt strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

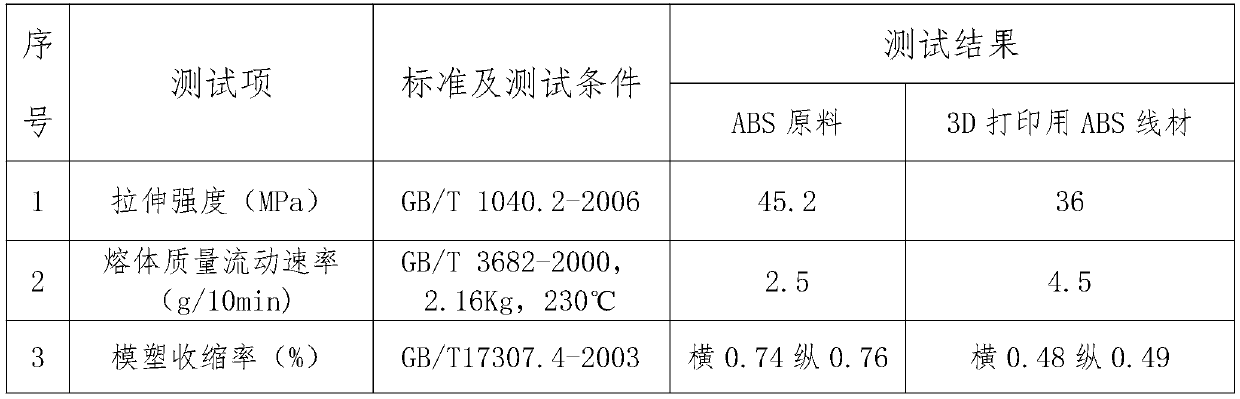

Embodiment 1

[0035] This embodiment provides a 3D printing ABS wire rod made of acrylonitrile-butadiene-styrene resin (ABS) particles, talcum powder masterbatch, calcium carbonate, styrene-butadiene-styrene block copolymer ( SBS), antioxidant, lubricant, compatibilizer and color masterbatch, wherein the mass ratio of each component added is: acrylonitrile-butadiene-styrene resin (ABS) is 82 parts, talcum powder masterbatch is 3 parts, 3 parts of calcium carbonate, 6 parts of styrene-butadiene-styrene block copolymer (SBS) powder, 0.5 parts of antioxidant, 0.5 parts of lubricant, 5 parts of compatibilizer, masterbatch 2 share;

[0036] This embodiment also provides a method for preparing the above-mentioned ABS wire for 3D printing, comprising the following steps:

[0037] a) Drying of raw materials: Dry ABS granules, talcum powder masterbatch, calcium carbonate and SBS powder in a blast drying oven at a drying temperature of 80°C and a drying time of 6 hours;

[0038] b) High-speed mixin...

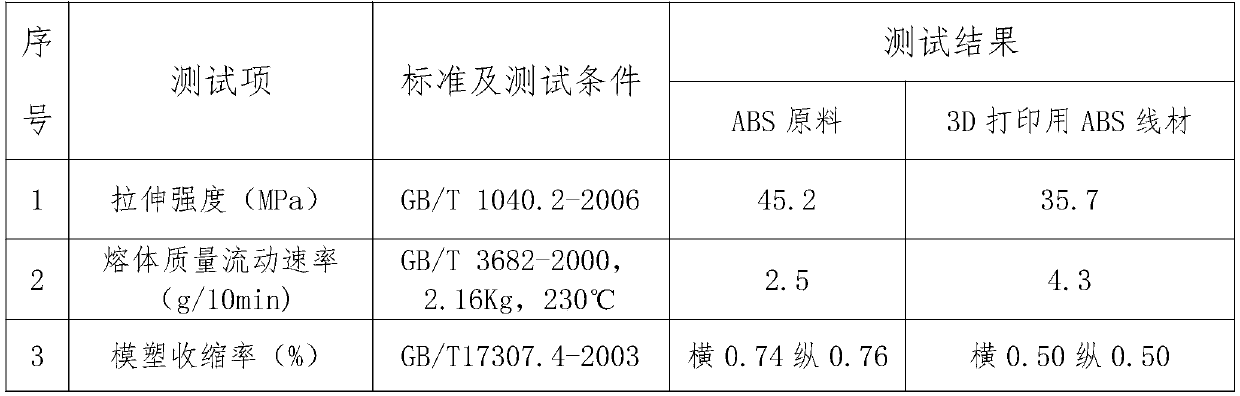

Embodiment 2

[0047] An ABS consumable for 3D printing provided in this example is composed of the following materials: ABS (Jihua 0215A) particles 85kg, talcum powder masterbatch 7kg, calcium carbonate 7kg, SBS powder 20kg, antioxidant 1.5kg, lubricant 1.5kg kg, compatibilizer 10kg, color masterbatch 5kg;

[0048] Described ABS particle is the blend of styrene, acrylonitrile and polybutadiene emulsion graft powder and styrene-acrylonitrile copolymer;

[0049] Described talcum powder masterbatch is the granule that talcum powder and polypropylene are mixed and granulated;

[0050] Described calcium carbonate is 1300 order calcium carbonate powders;

[0051] Described SBS powder is triblock copolymer;

[0052] Described antioxidant is antioxidant 1010;

[0053] Described lubricant is polyolefin lubricant;

[0054] Described compatibilizer is maleic anhydride grafted ABS compatibilizer;

[0055] The color masterbatch is a resin-loaded super-constant pigment aggregate;

[0056] This embo...

Embodiment 3

[0067] An ABS consumable for 3D printing provided in this example is composed of the following materials: 60kg of ABS (Daqing Petrochemical 750A) particles, 1kg of talcum powder masterbatch, 1kg of calcium carbonate, 5kg of SBS powder, 0.5kg of antioxidant, 0.5kg of lubricant kg, compatibilizer 2kg, color masterbatch 1kg;

[0068] Described ABS particle is the blend of styrene, acrylonitrile and polybutadiene emulsion graft powder and styrene-acrylonitrile copolymer;

[0069] Described talcum powder masterbatch is the granule that talcum powder and polypropylene are mixed and granulated;

[0070] Described calcium carbonate is 1100 order calcium carbonate powders;

[0071] Described SBS powder is triblock copolymer;

[0072] Described antioxidant is antioxidant 168;

[0073] Described lubricant is polyolefin lubricant;

[0074] Described compatibilizer is maleic anhydride grafted ABS compatibilizer;

[0075] The color masterbatch is a resin-loaded super-constant pigment a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com