System and method for controlling diameter of absorbable suture lines in spinning forming process

A forming process and suture technology, which is applied in the field of suture manufacturing, can solve problems such as uneven diameter of suture, uneven thickness of stock solution, difficult control of spinning speed of spinneret, etc., and achieve faster and stable identification good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The present invention will be further described below in conjunction with accompanying drawing:

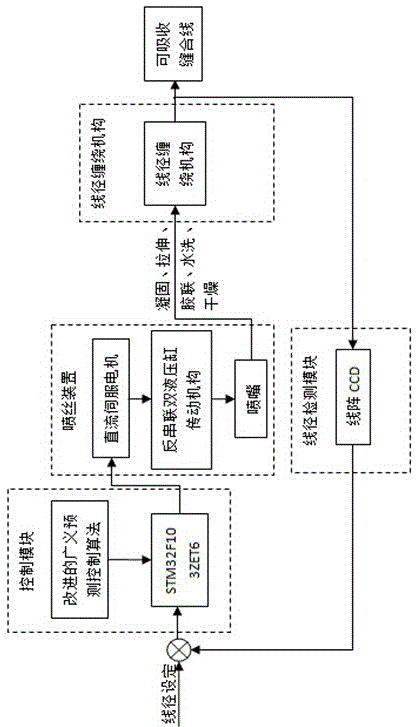

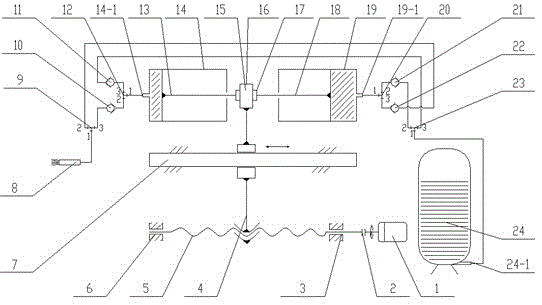

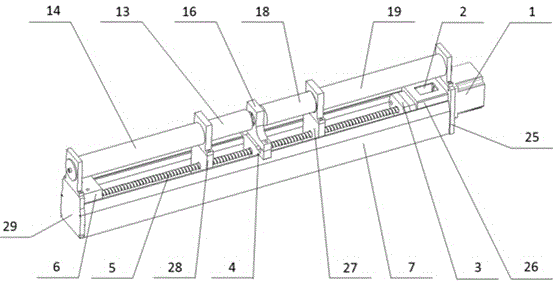

[0065] Such as Figure 1 to Figure 5 As shown, the wire diameter control system during the spinning and forming process of absorbable sutures includes a wire diameter detection module, a wire warp winding mechanism, a control module, and a spinning device.

[0066] The spinning device includes a DC servo motor, an anti-series double hydraulic cylinder transmission mechanism, and three parts of the nozzle. The STM32F103ZET6 chip of the control module passes through the DC servo motor 1 of the spinning device, the anti-series double hydraulic cylinder transmission mechanism, the nozzle 8 and the wire warp. The mechanism is connected, and the wire diameter detection module is respectively connected with the control module and the wire winding mechanism.

[0067] The control module uses a 32-bit microcontroller STM32F103ZET6 chip based on ARMCortex-M3 core as the data processi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com