Method for improving volume resistivity of carbon fiber, modified carbon fiber and application of modified carbon fiber

A technology of volume resistivity and carbon fiber, which is applied in the field of modifying carbon fiber and improving the volume resistivity of carbon fiber, which can solve the problems of difficult insulating materials, high dielectric constant, and low packing density, so as to reduce the dielectric constant and improve the insulation performance , The effect of increasing the volume resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

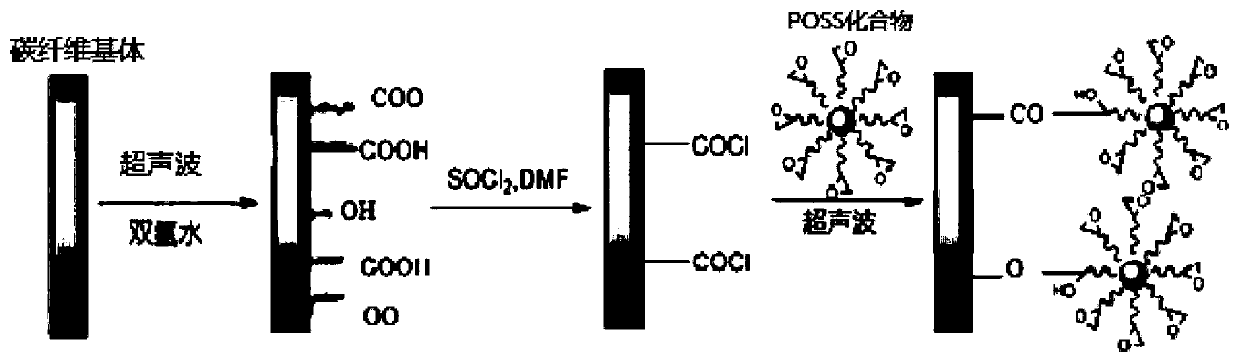

[0059] This embodiment provides a method for increasing the volume resistivity of carbon fibers, the steps are as follows:

[0060] (1) Preoxidation

[0061] Prepare 8 wt% H with deionized water 2 o 2 The solution was put into a 1000mL Erlenmeyer flask, the chopped carbon fibers were completely immersed, and the oxidation treatment was performed in an ultrasonic water bath for 60min, the ultrasonic power was 150W, the frequency was 50000Hz, and the temperature was set at 45°C. Then rinse the surface-treated chopped carbon fibers with deionized water until neutral, put them in a vacuum oven at 110°C for 2 hours, and then set aside.

[0062] (1') acid chloride

[0063]Pre-oxidized carbon fibers were dried at 110°C for 2 hours and placed in 500mL of SOCl 2 and 5mL of DMF in the mixed solution (the SOCl 2 The amount accounts for 8% of the mass of the carbon fiber of the pre-oxidation), ultrasonic heating to 70 ℃ for 2h, decompression distillation to remove excess SOCl 2 , to...

Embodiment 2

[0067] This embodiment provides a method for increasing the volume resistivity of carbon fibers, the steps are as follows:

[0068] (1) Preoxidation

[0069] Prepare 10 wt% H with deionized water 2 o 2 The solution was put into a 500mL Erlenmeyer flask, the chopped carbon fibers were completely immersed, and the ultrasonic water bath was oxidized for 30min, the ultrasonic power was 200W, the frequency was 40000Hz, and the temperature was set at 45°C. Then rinse the surface-treated chopped carbon fibers with deionized water until neutral, put them in a vacuum oven at 110°C for 2 hours, and then set aside.

[0070] (2) Grafting reaction

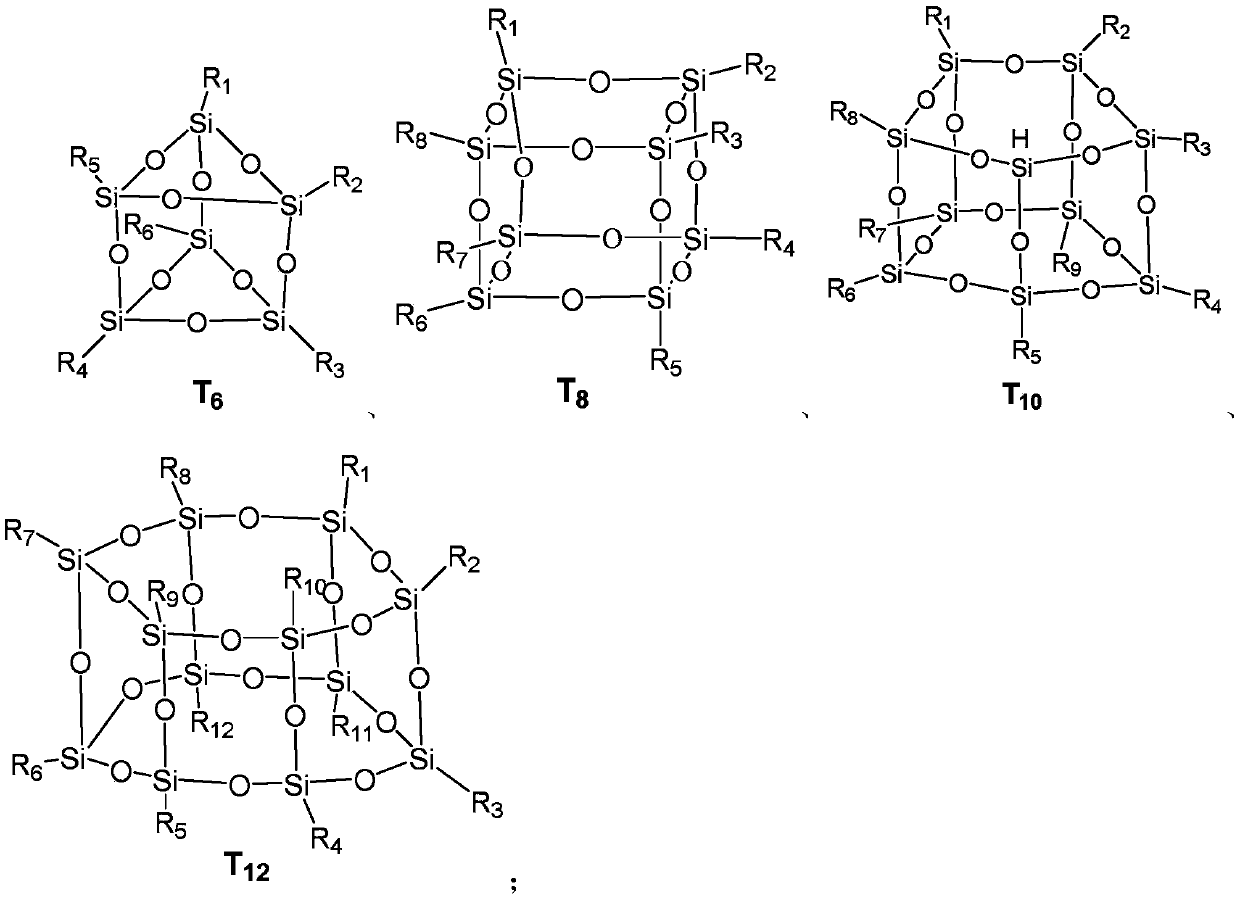

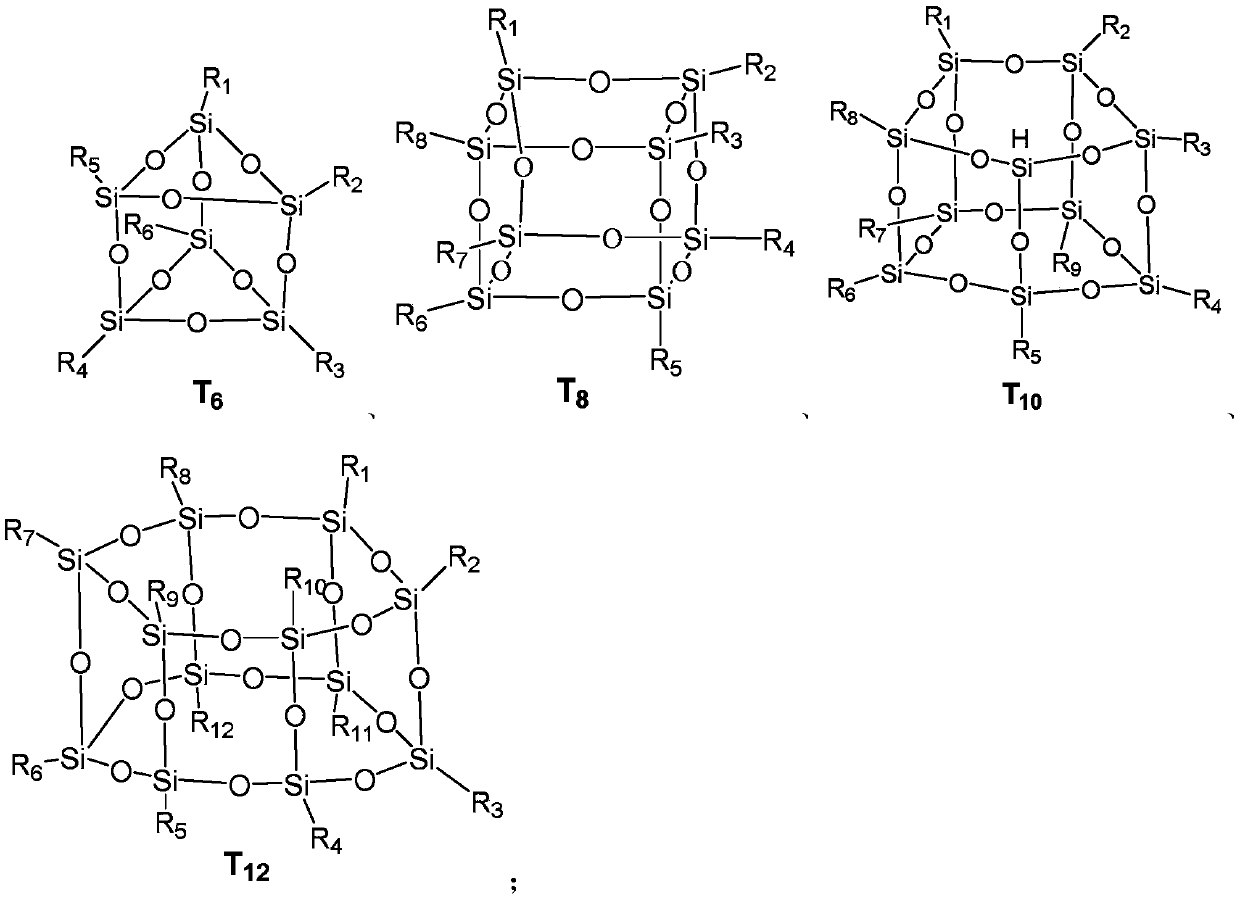

[0071] Put 400mL of propylene glycol monoethyl ether / tetrahydrofuran mixture into 1000mL Erlenmeyer flask, add 200g of pre-oxidized carbon fibers, after ultrasonic vibration for 30min, add 0.6g of POSS compound EP0421 containing active groups to obtain mixed solution (the concentration of POSS compound 0.1wt%), react in an ultrasonic water ...

Embodiment 3

[0073] This embodiment provides a method for increasing the volume resistivity of carbon fibers, the steps are as follows:

[0074] (1) Preoxidation

[0075] Prepare 15 wt% H with deionized water 2 o 2 The solution was put into a 500mL Erlenmeyer flask, the chopped carbon fibers were completely immersed, and subjected to an ultrasonic water bath oxidation treatment for 45min, with an ultrasonic power of 150W, a frequency of 30000Hz, and a temperature setting of 35°C. Then rinse the surface-treated chopped carbon fibers with deionized water until neutral, put them in a vacuum oven at 110°C for 2 hours, and then set aside.

[0076] (2) Grafting reaction

[0077] Put 400mL of propylene glycol monoethyl ether / tetrahydrofuran mixture into 1000mL Erlenmeyer flask, add 200g of pre-oxidized carbon fibers, after ultrasonic vibration for 30min, add 60g of POSS compounds (SO1400 and EP0409) containing active groups to obtain a mixed solution (POSS The concentration of the compound is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com