Fiber-reinforced polyethylene glycol terephthalate composite material and preparation method thereof

A polyethylene terephthalate and composite material technology, which is applied in the field of fiber-reinforced polymer composite materials, can solve the problems of not obtaining performance composite materials, not improving basalt fiber-PET inorganic-organic phase interface, gap, etc. , to achieve the effects of excellent stability, simple molding process and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

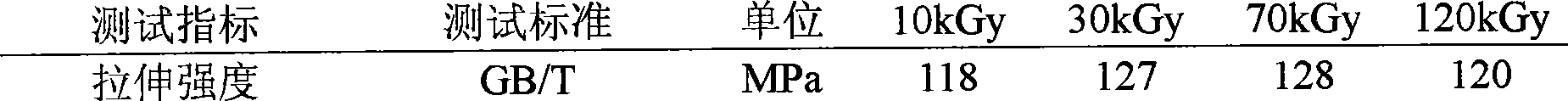

[0034] First dry 850g of PET and 150g of continuous long basalt fiber, then mix PET, 10g of TAIC, 10g of boron nitride and 10g of 3,5-di-tert-butyl-4-hydroxybenzyl diethyl phosphate, and add it to bis In the screw extruder, during the melt extrusion process, basalt fiber bundles are introduced from the fiber feeding port, the extrusion temperature is 275°C, the head temperature is 260°C, the extruded material is cooled and then pelletized to obtain the masterbatch; After the masterbatch is dried to a moisture content of less than 1.5‰, in N 2 Irradiate with Co-60 source under protection, the dose is 10kGy, 30kGy, 70kGy, 120kGy. Its mechanical properties are shown in Table 1:

[0035] Table 1: Changes in mechanical properties of reinforced PET after irradiation

[0036]

[0037]

Embodiment 2

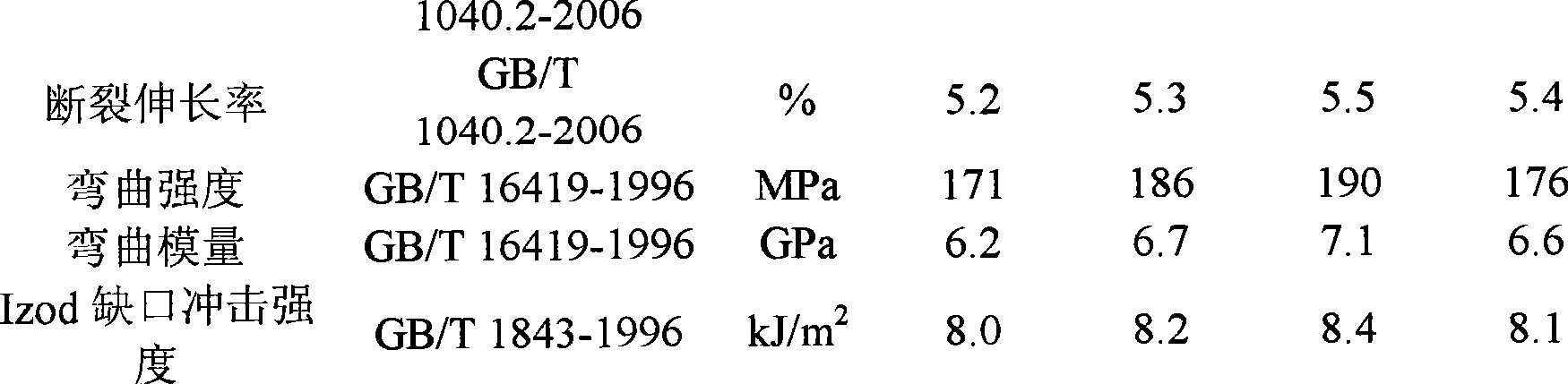

[0039] First dry 800g of PET and 200g of continuous long basalt fibers as raw materials, then dry PET, 20g of PETA, 10g of boron nitride and 20g of n-octadecyl propionate Mix evenly and add to the twin-screw extruder. During the melt extrusion process, introduce basalt fiber bundles from the fiber feeding port. The extrusion temperature is 260°C, and the head temperature is 260°C. The extruded materials are cooled and then cut. Granules to obtain the masterbatch; after the masterbatch is dried to a moisture content of less than 1.5‰, the 2 Irradiate with Co-60 source under protection, the dose is 10kGy, 30kGy, 70kGy, 120kGy. Its mechanical properties are shown in Table 2:

[0040] Table 2: Changes in mechanical properties of reinforced PET after irradiation

[0041]

Embodiment 3

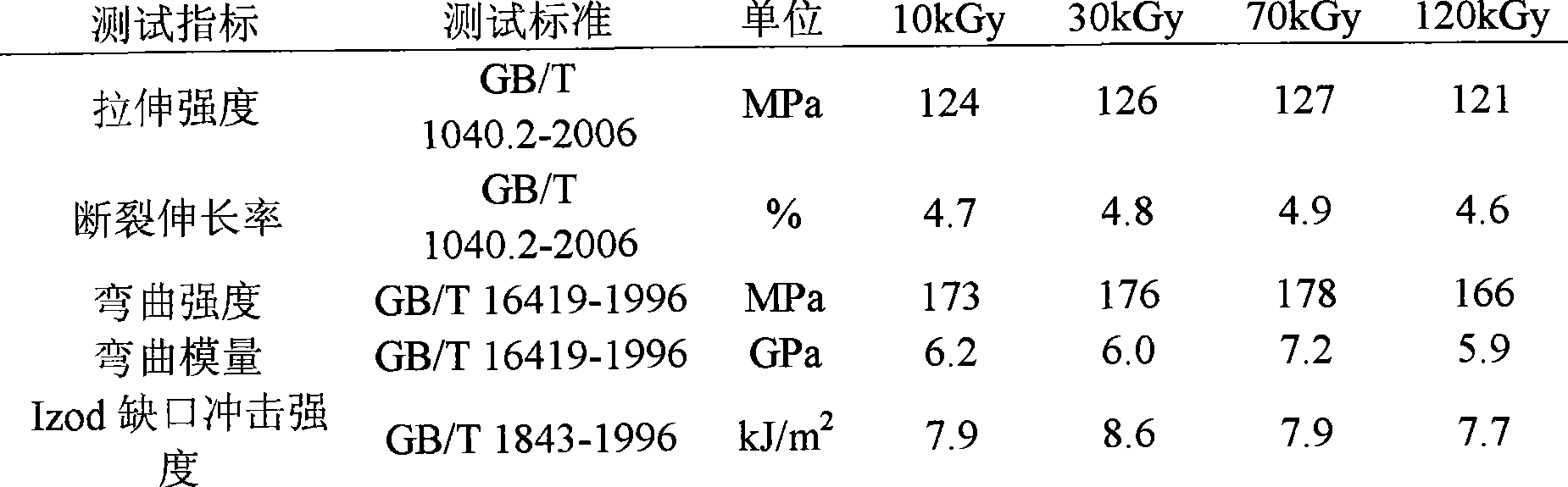

[0043]First, dry raw material 700g PET and 300g continuous long glass fiber, then mix PET, 15g TMPTA, 10g boron nitride and 30g triphenyl phosphite evenly, add to twin-screw extruder, during the melt extrusion process, Introduce glass fiber bundles from the fiber feeding port, extrusion temperature is 240°C, head temperature is 260°C, the extruded material is cooled and then pelletized to obtain the masterbatch; after the masterbatch is dried to a moisture content of less than 1.5‰, the 2 Irradiate with Co-60 source under protection, the dose is 10kGy, 30kGy, 70kGy, 120kGy. Its mechanical properties are shown in Table 3:

[0044] Table 3: Changes in mechanical properties of reinforced PET after irradiation

[0045]

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com