Preparation equipment of triazinone herbicide

A herbicide and equipment technology, which is applied in the field of preparation equipment of triazine herbicides, can solve the problems of air pollution, air pipe blockage, easy crystal entry, etc., and achieve the effect of prolonging the service life and preventing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

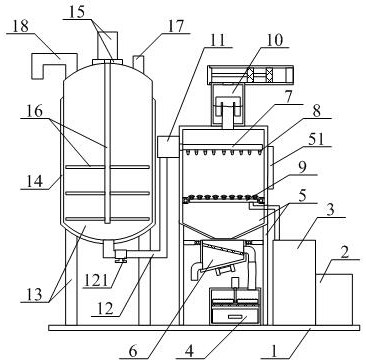

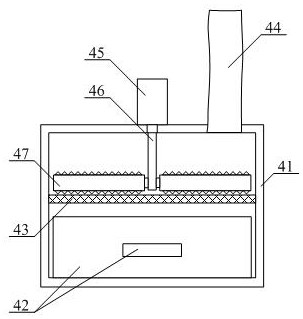

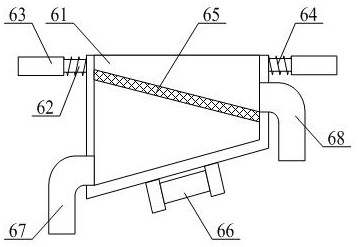

[0038] as attached figure 1 And attached figure 2 As shown, a preparation device for triazine herbicides includes a base plate 1, an air compressor 2, a cooler 3, a crystal crushing frame structure 4, a condensation solidification tank 5, a filter frame structure 6, and a liquid outlet pipe 7. Atomizing nozzle 8, anti-clogging air outlet pipe structure 9, exhaust gas filter frame structure 10, water pump 11, infusion pipe 12, distillation tank 13, heating jacket 14, rotating motor 15, stirring frame 16, feed pipe 17 and steam outlet pipe 18. The air compressor 2 is bolted to the upper right side of the bottom plate 1; the cooler 3 is arranged on the left side of the air compressor 2 and is bolted to the upper part of the bottom plate 1; the crystal crushing frame The structure 4 is arranged on the top of the bottom plate 1; the condensation solidification tank 5 is bolted to the top of the bottom plate 1; the filter frame structure 6 is installed on the bottom of the condens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com