Reductive decomposition method of phosphogypsum by microwave process

A technology of phosphogypsum and microwave method, which is applied in the field of microwave chemistry, can solve the problems of limiting the utilization value of decomposition tailings and poor gypsum decomposition effect, and achieve the effects of reducing drying time, improving drying efficiency, and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

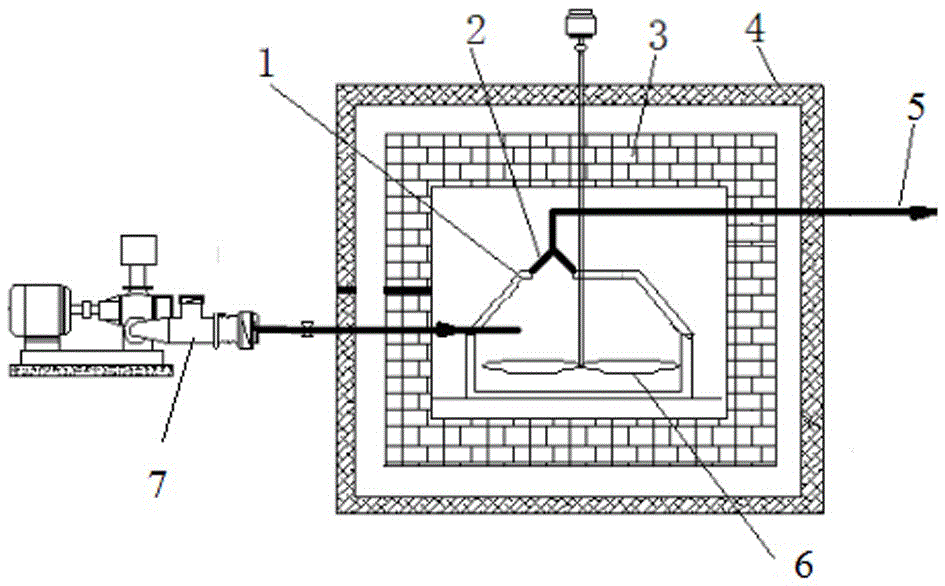

[0038] A microwave reaction device with an effective volume of 50 L was designed for the reduction and decomposition of phosphogypsum. The material is placed in the reaction chamber 1, and an appropriate amount of air is blown in by the air pump 7 to maintain the weak reducing atmosphere of the reaction system. The gas after the reaction is discharged from the reactor through the gas outlet 2 through the flue gas pipe 5; the powder of the phosphogypsum material is relatively fine, and the reduction During the decomposition process, the stirring paddle 6 is used to mix the materials intermittently to complete a sufficient reaction, and after the reaction is completed, the roasted slag is taken out for subsequent processing.

[0039] Mix phosphogypsum and coke in proportion according to the mass ratio of 1:0.06, and add wave-absorbing auxiliary materials and mineralizers. The wave-absorbing auxiliary materials account for 5% of the total mass of the mixture, including iron oxide,...

Embodiment 2

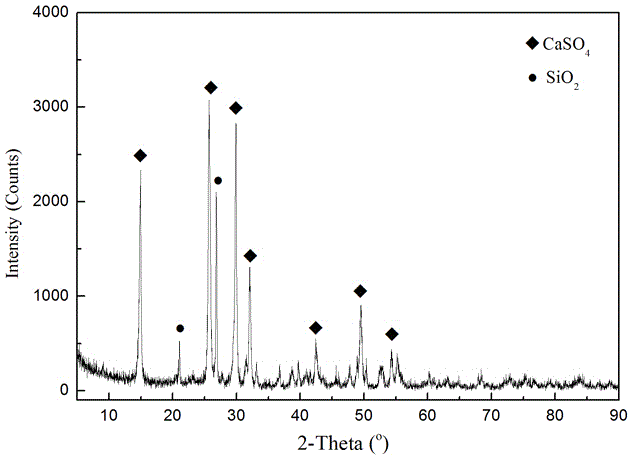

[0041] Using the same microwave reaction device as in Example 1, the proportion of reduced coal, the drying process and the process flow are also exactly the same as in Example 1. The microwave-absorbing auxiliary materials account for 4% of the total mass of the mixture, including iron oxide, activated alumina, and ferrite, which are 45%, 45%, and 10% of the active materials, respectively. The amount of mineralizer added is 4% of the total weight of the mixture. The mineralizers include fluorite, cryolite and magnesium oxide, accounting for 40%, 40% and 20% of the composite mineralizer respectively. Phosphogypsum was dried for 20 min at a microwave output frequency of 915 MHz to remove moisture; after sieving with a 200-mesh sieve, 20 kg of dried phosphogypsum mixture was sent to the reaction chamber of the decomposition device, and the microwave output frequency was 2450 MHz, 1000 ℃ reduction decomposition for 45 min, take out the roasted slag, its XRD pattern is shown in ...

Embodiment 3

[0043] Using the same microwave reaction device as in Example 1, the proportion of reduced coal, the drying process and the process flow are also exactly the same as in Example 1. The microwave-absorbing auxiliary materials account for 6% of the total mass of the mixed materials, including iron oxide, activated alumina, and activated silica, which are 45%, 45%, and 10% of the active materials, respectively. The addition amount of the mineralizer is 3% of the total weight of the mixture, and the mineralizer includes fluorite and cryolite, accounting for 50% and 50% of the composite mineralizer respectively. Phosphogypsum was dried for 18 minutes under the microwave output frequency of 2450MHz to remove moisture; after sieving with a 180-mesh sieve, 20 kg of dried phosphogypsum mixture was sent to the reaction chamber of the decomposition device, and the microwave output frequency was 2450MHz. MHz, 950°C reduction decomposition for 60 min, the roasted slag was taken out, its XRD...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com