Flow guiding device for heat pump drying box

A technology of diversion device and drying box, which is applied in the direction of drying, drying machine, drying gas arrangement, etc., which can solve the problems of low drying efficiency, inability to ensure uniform drying of crops, and accumulation of cold air, so as to ensure the drying The effect of dry efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

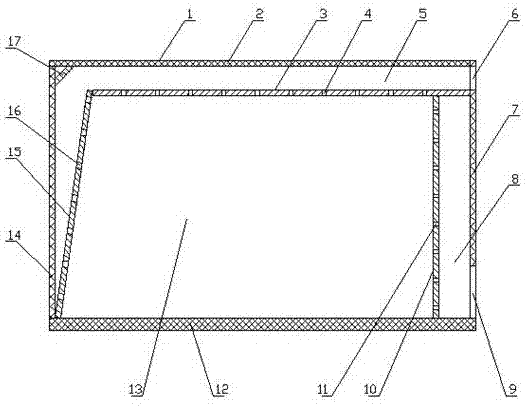

[0032] Referring to the accompanying drawings: in order to solve the above problems, the technical solution adopted in the present invention is: a flow guiding device for a heat pump drying box, including a drying box 1,

[0033] The upper and lower parts of the front wall 7 of the drying box 1 are respectively provided with an air inlet 6 and an air outlet 9, and the rear deflector 15 and the upper deflector 3 are respectively installed on the inner rear side and the upper side of the drying box 1. , the upper deflector 3 is located below the air inlet 6; the rear deflector 15 and the upper deflector 3 divide the drying box 1 into an air inlet channel 8 and a drying area 13, and the rear deflector 15 and / or the upper deflector 3 is provided with an air outlet; the air outlet includes the air leakage hole 4 and the drainage hole 16 respectively arranged on the upper deflector 3 and the rear deflector 15 .

[0034] The front side of the drying box 1 is also provided with a fron...

Embodiment 2

[0043] Compared with Embodiment 1, the flow guiding device for the heat pump drying box 1 of this embodiment has the following differences:

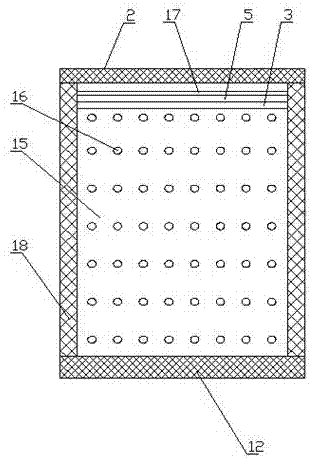

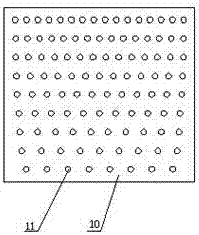

[0044] The upper deflector 3 is connected between the side walls 18 on both sides of the drying box 1 in such a way that the front end is inclined downward, the angle between the upper deflector 3 and the horizontal plane is 2°, and the vent hole 4 The total area of the upper deflector is 5% of the area of the upper deflector 3, and the longitudinal distance and the transverse distance between the adjacent said vent holes 4 are respectively 5% of the length and width of the upper deflector 3; Installation is carried out in a downwardly inclined manner, so that the hot air flow can flow to the rear deflector 15 more smoothly, avoiding the excessive pressure of the hot air flow in the air inlet channel 5 of the upper deflector 3 section, and keeping the total area of the vent hole 4 unchanged Under certain circumstances, increasing t...

Embodiment 3

[0048] Compared with Embodiment 1, the deflector for the heat pump drying box 1 of this embodiment has the following differences: In this embodiment, a rear deflector 10 and an upper deflector are respectively installed on the rear side and the upper side of the drying box. Deflector 3, instead of a front deflector, the rear deflector 10 and the upper deflector 3 divide the drying box into an air inlet channel 5 and a drying area 13,

[0049] Specifically, the hot air enters the air inlet channel 5 from the air inlet 6, and when the hot air flows through the air inlet channel 5 of the upper deflector 3 section, due to the high wind pressure, part of the hot air will flow into the oven from the vent hole 4 of the upper deflector 3. Dry area 13; when the hot air enters the air inlet channel 5 of the rear deflector 15, it will flow into the drying area 13 from the drainage holes 16 on the rear deflector 15; the hot air after drying the materials in the drying area 13 Directly flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com