Efficient rice drying machine

A dryer and rice technology, which is applied in the direction of dryers, drying solid materials, drying gas arrangement, etc., can solve the problems of wide land occupation, large size of dryers, poor rice milling effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

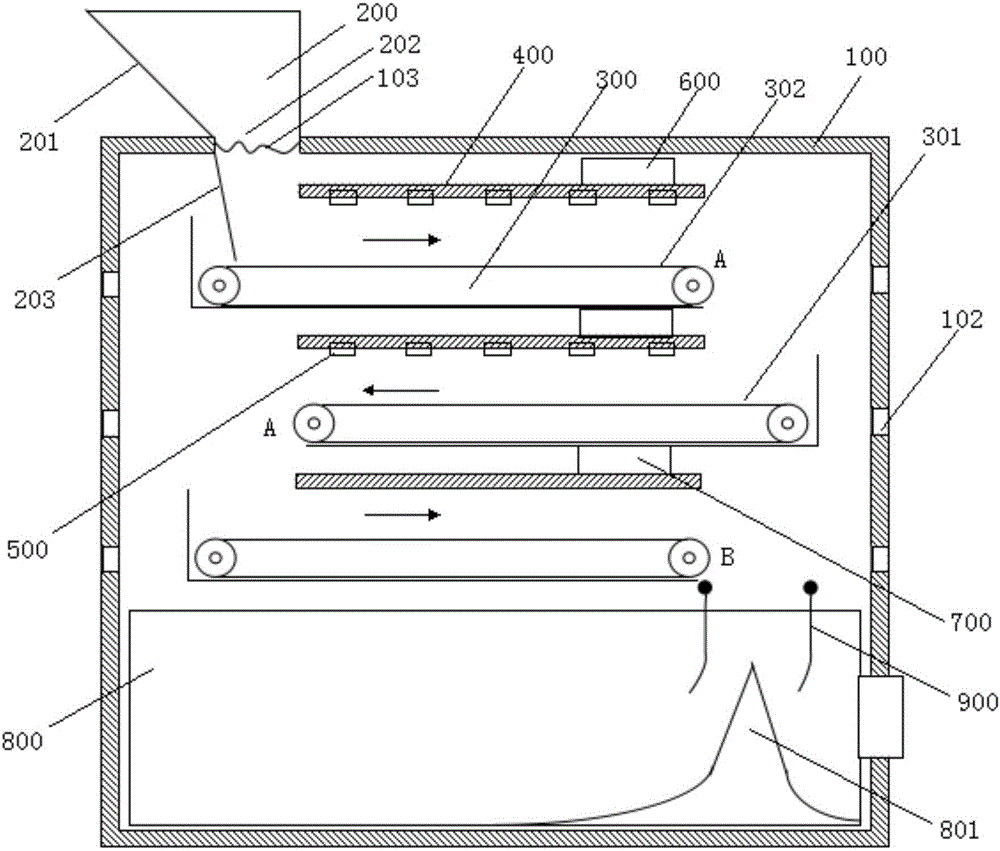

[0020] Such as figure 1 As shown, the present invention provides a kind of high-efficiency rice dryer, which comprises:

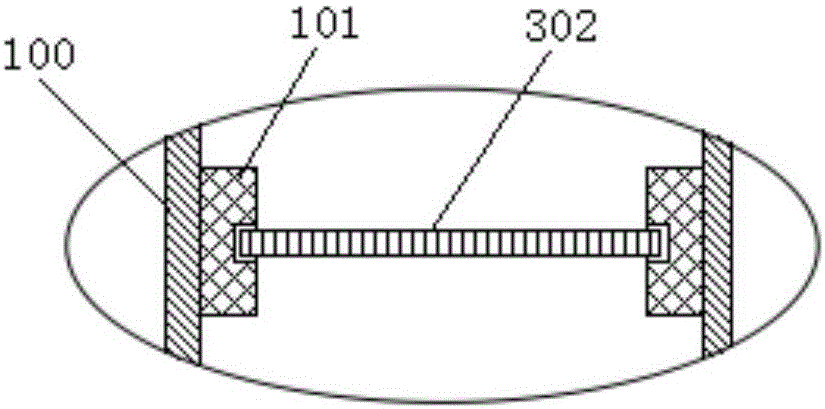

[0021] The casing 100 is in the shape of a flat cube, the top of the casing is provided with a feed hopper 200, and one side of the feed hopper is set towards an inclined surface 201 inside the casing, and the inclined surface is from the top to the The width of the fixing place with the casing gradually narrows and forms a 30-50cm wide feed inlet 202 at the fixing place of the casing (the feed inlet 202 of this design can make paddy blanking more concentrated and faster), and the casing is A guide plate 203 with an inclination smaller than the inclined surface is also connected below the material inlet;

[0022] A plurality of paddy conveying crawlers 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com