Patents

Literature

87 results about "Shrinkage strain" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

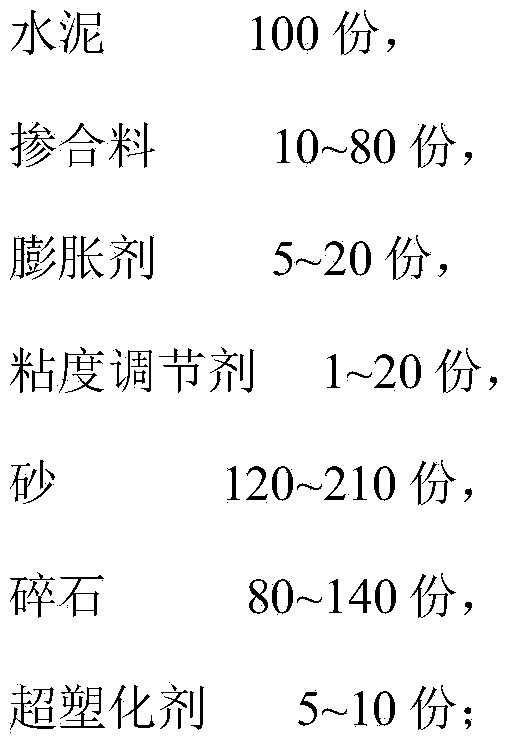

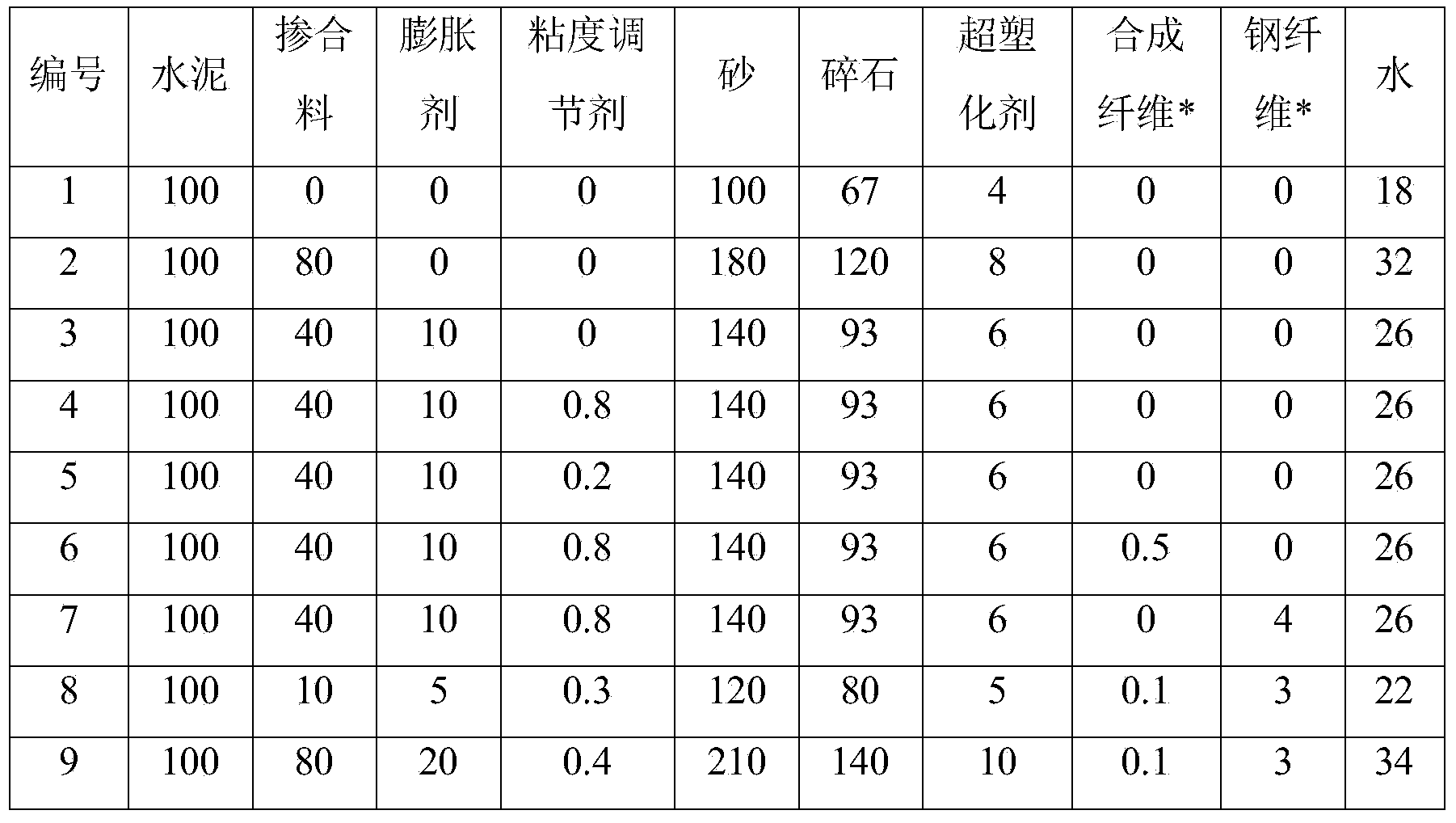

Full-particle size ultrahigh-performance concrete composition

The invention discloses a full-particle size ultrahigh-performance concrete composition which is prepared from the following components: 100 parts of cement, 10-80 parts of admixture, 5-20 parts of expanding agent, 1-20 parts of viscosity regulator, 120-210 parts of sand, 80-140 parts of rubble and 5-10 parts of super plasticizer while certain volume dosage of fiber is added. The full-particle size ultrahigh-performance concrete composition disclosed by the invention has controllable rheological property and shrinkage strain property and ultrahigh mechanical property and durability. Water is directly added on the site according to a proportion, and the full-particle size ultrahigh-performance concrete can be obtained through forced stirring.

Owner:JIANGSU SOBUTE NEW MATERIALS

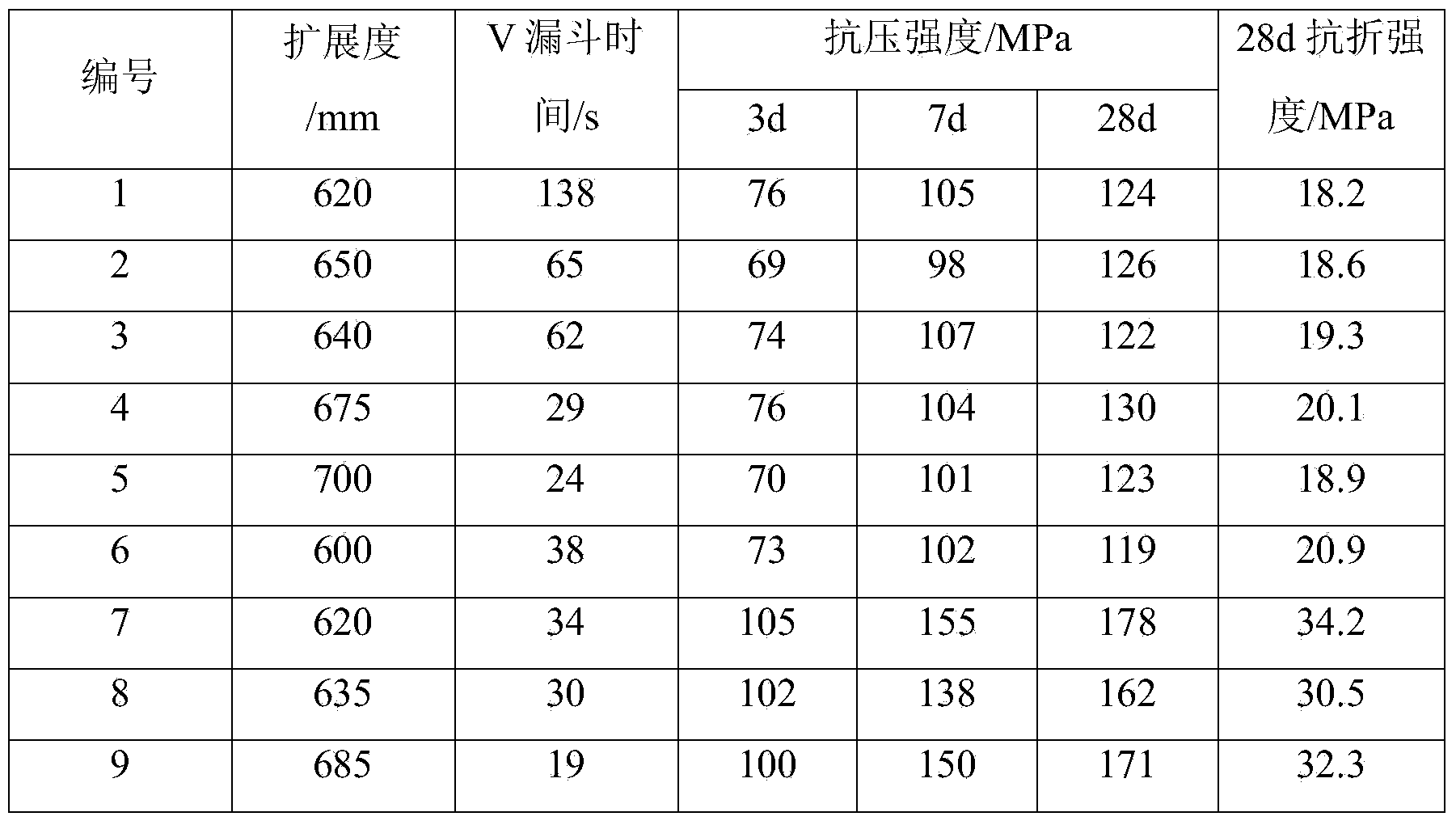

Systematic detection method for anti-cracking performance of concrete

InactiveCN103513018AHigh safety factor against crackingEnsure safetyMaterial testing goodsStress concentrationEngineering

The invention relates to a systematic detection method for an anti-cracking performance of concrete and in particular relates to a systematic detection method for comprehensively judging the anti-cracking performance of the concrete by detecting an anti-cracking safety coefficient, a shrinkage strain amount, a strength and elastic modulus development curve, a strain concentration point and the restriction degree. The detection method comprises the following steps of detecting a temperature strain parameter of the concrete to judge the anti-cracking safety coefficient of the concrete; detecting a shrinkage strain value of the concrete to judge the shrinkage strain amount of the concrete; detecting the maturity of the concrete to construct the strength and the elastic modulus development curve; simulating and calculating the strain concentration point of the concrete through a central processing unit; detecting a friction coefficient of a concrete entity model to judge the restriction degree of the concrete; comprehensively evaluating the anti-cracking performance of the concrete according to the steps. According to the systematic detection method, the anti-cracking performance of the concrete can be effectively detected, and the manufacturing quality of the concrete is improved, so that the concrete can meet a requirement of a high-standard submarine construction environment.

Owner:CCCC FOURTH HARBOR ENG INST +1

Color protection and combined drying method of apple chips

InactiveCN101991070AKeep the original color and tasteLess nutrient lossFood preparationSulfurEngineering

The invention relates to a color protection and a combined drying method of apple chips, which comprises the following steps of: peeling, denucleating and slicing apples; immediately placing the sliced apples into sulfur-free color protection liquid; cleaning the apple slices after being subject to the color protection fixing by clean water; paving and placing the apple slices into a disc to be sent into a hot air drying box for being dried; carrying out vacuum low-temperature drying after the hot air drying is completed; and encapsulating the dried and checked apple chips to complete the production of the apple chips. The invention belongs to the combined drying process of the apple chips, which prepares the sulfur-free color protection liquid of the apple chips according to the browning prevention mechanism of the apple chips and the characteristics of the water losing process of the apple slices, and combines the hot air drying with the vacuum low-temperature drying technology. The sulfur-free color protection liquid of the invention effectively prevents the browning of the apple slices and the shrinkage strain in the drying process, greatly reserves the original color and original taste of the apples, and realizes the sulfur-free color protection. The invention combines the hot air drying and the vacuum low-temperature drying, reduces the drying energy consumption and improves the drying efficiency, the produced apple chips have low nutrient loss, and the invention has the advantages of health and environment protection.

Owner:SHAANXI UNIV OF SCI & TECH

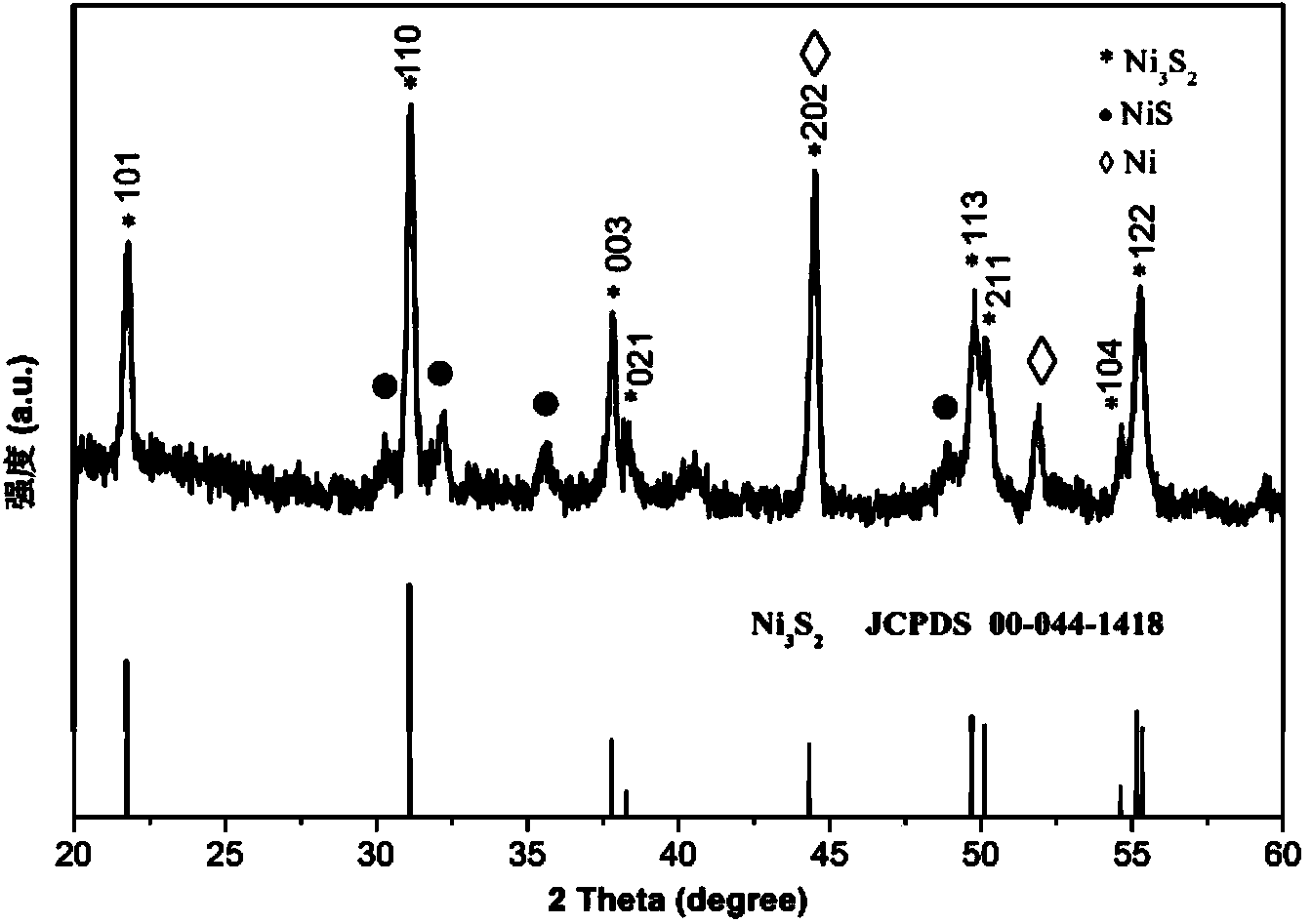

Preparation method for electrode with three-dimensional structure formed by coating nickel sulfide by fold graphene through self-repairing

ActiveCN104037416AFast charge and dischargeIncreased diffusion rateCell electrodesSecondary cellsMagnetic tension forceWater baths

The invention relates to a preparation method for an electrode with a three-dimensional structure formed by coating nickel sulfide by fold graphene through self-repairing. The preparation method comprises the following steps: (1) preparing NaOH solution, adding S and Na2S.9H2O into the NaOH solution, and stirring the mixture in a water bath; (2) adding a graphene dispersion liquid, and stirring by using magnetic force; (3) adding dilute hydrochloric acid, adjusting the pH of the solution, and stirring the solution by using the magnetic force; (4) performing suction and filtration to obtain graphene-coating sulfur particles, and drying the sulfur particles in air; (5) soaking the sulfur particles by using commercial nickel foam, and preserving for later use; (6) placing the soaked sulfur particles in a reaction kettle lining, adding de-ionized water into the sulfur particles, encapsulating and performing hydrothermal reaction on the mixture, and cooling a reaction product to room temperature; and (7) washing the reaction product by using alcohol and water once respectively, soaking the reaction product in hydrazine hydrate aqueous solution, and finally drying the soaked reaction product in the air. The preparation method has the beneficial effects that the electrode is prepared on the basis of a shrinkage strain drive mechanism; high-current fast charge and discharge can be realized; in addition, the cycling times can reach 1,000, and the capacity does not decay basically.

Owner:WUHAN UNIV OF TECH

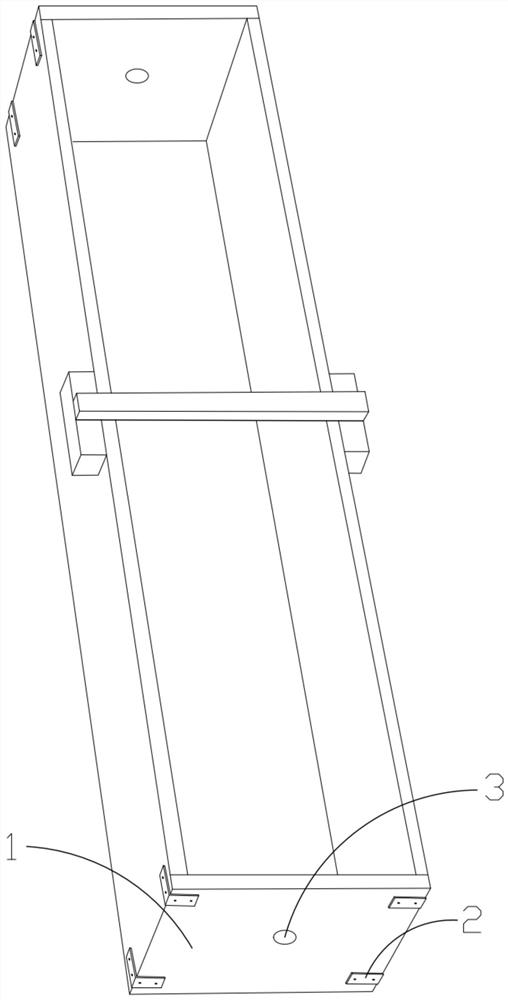

Concrete structure combined strain monitoring unit and concrete state evaluation method

InactiveCN107607412AEasy to useMaterial strength using steady shearing forcesCoil springVibrating wire

The present invention discloses a concrete structure combined strain monitoring unit, which comprises a cube main body, wherein 18 vibrating wire strain sensors are arranged on the diagonal lines of each edge and each surface of the cube main body, both ends of each vibrating wire strain sensor are respectively connected to the bolt ball nodes positioned at eight top corner positions of the cube main body through connection rods and helical springs in a threaded manner, a cylindrical separation cylinder with an opening top portion is fixedly arranged in the cube main body, the cylinder wall ofthe separation cylinder sequentially comprises an elastic separation net, a water-permeation and gas-permeation layer and an elastic separation net from outside to inside, and a reference sensor formeasuring the concrete temperature and the shrinkage strain in the absence of a load is centrally arranged in the separation cylinder. The present invention further provides a concrete state evaluation method based on the combined strain monitoring unit. According to the present invention, with the concrete structure combined strain monitoring unit, the force applying on the concrete structure canbe accurately analyzed while the comparing to the index in the concrete failure criterion can be performed according to the requirement, and the possibility of concrete cracking can be evaluated.

Owner:SOUTH CHINA UNIV OF TECH +1

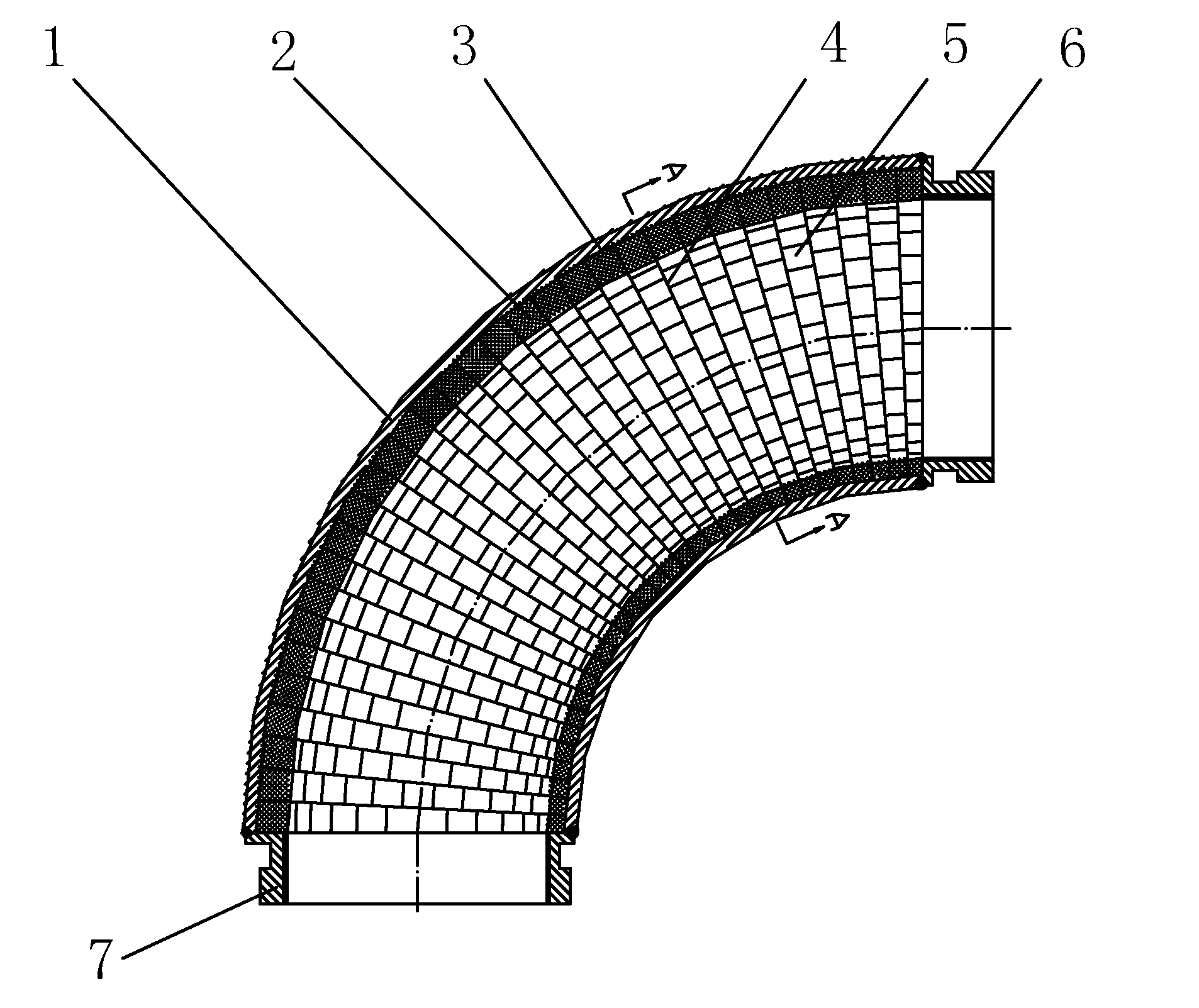

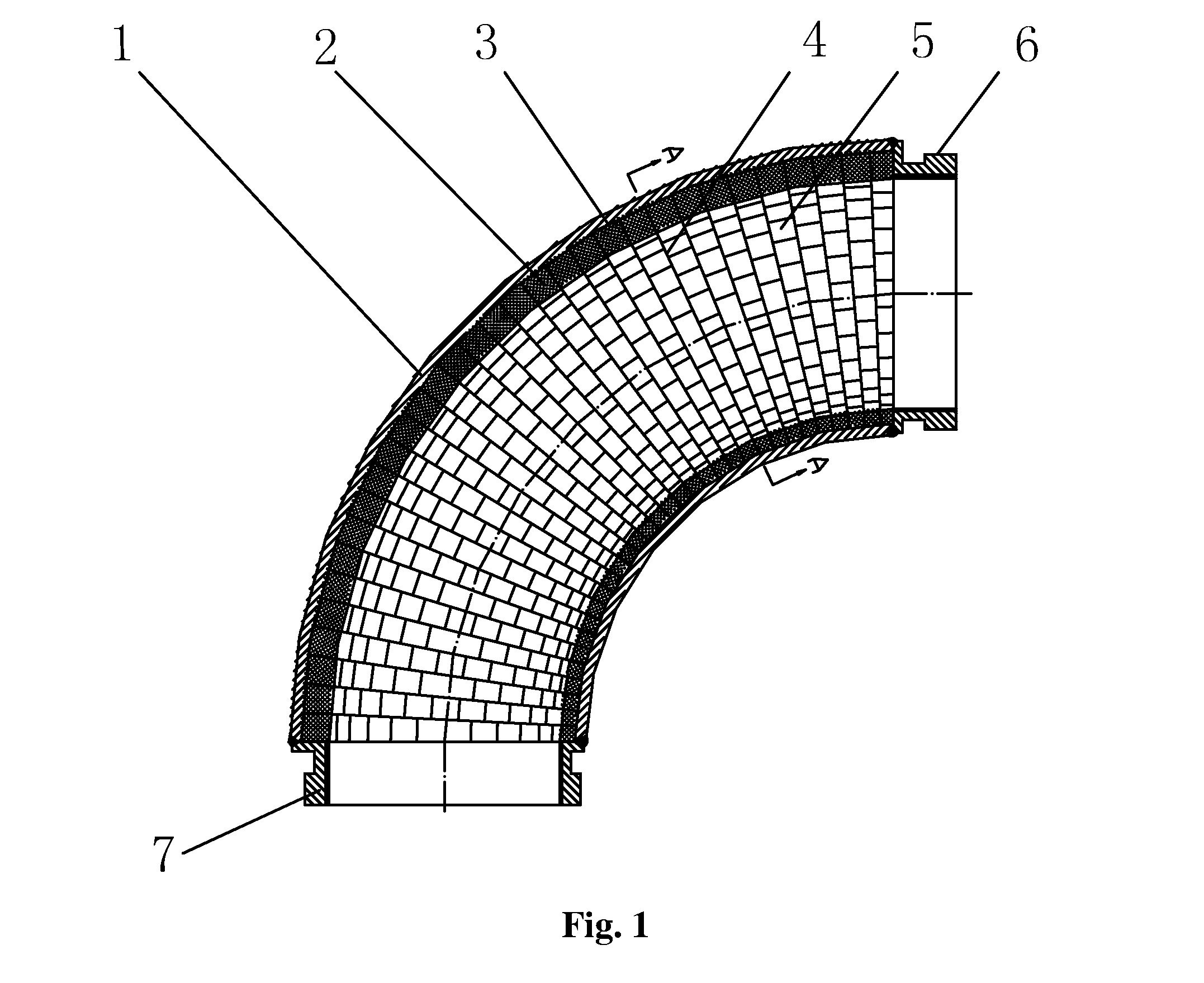

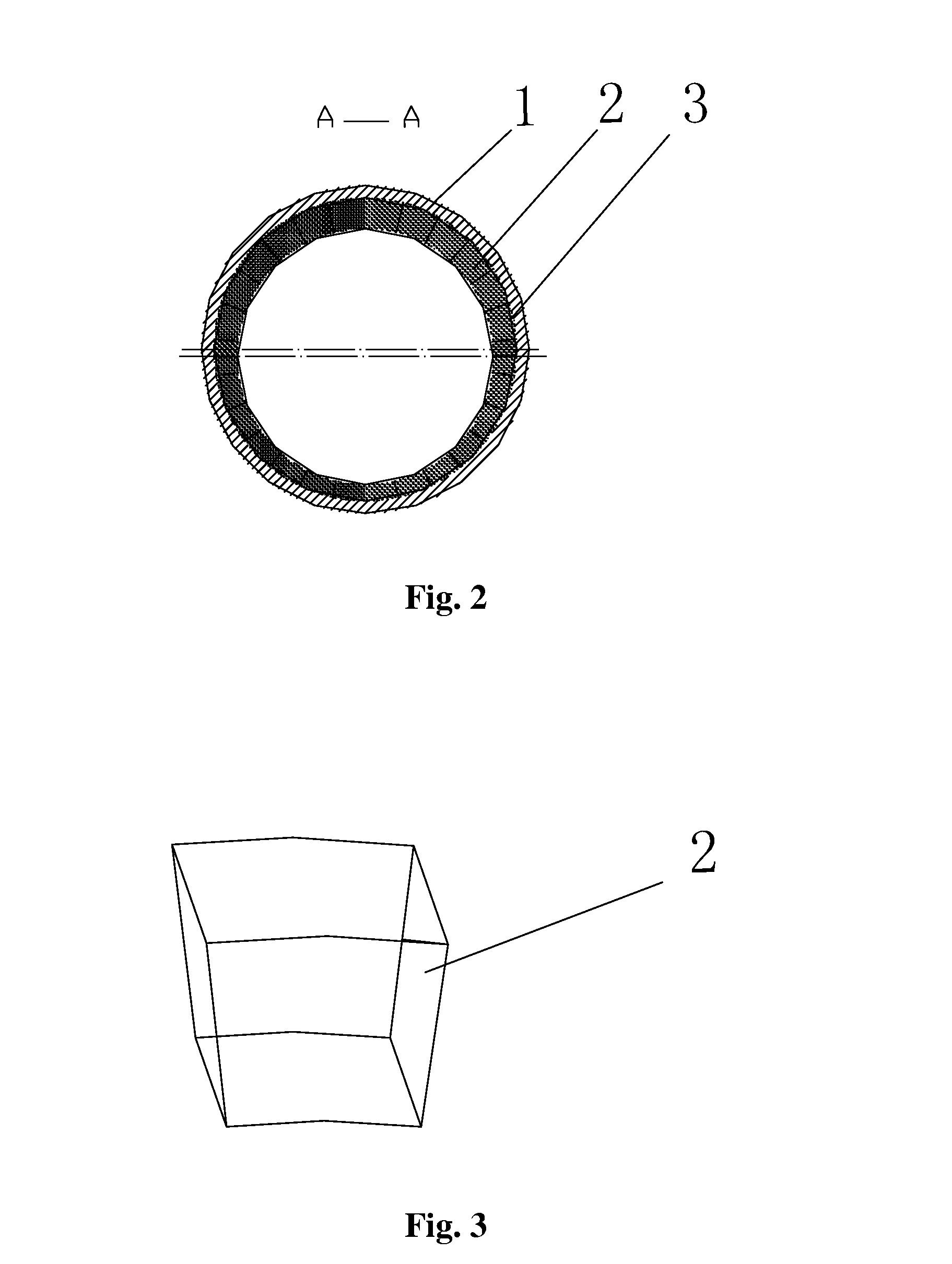

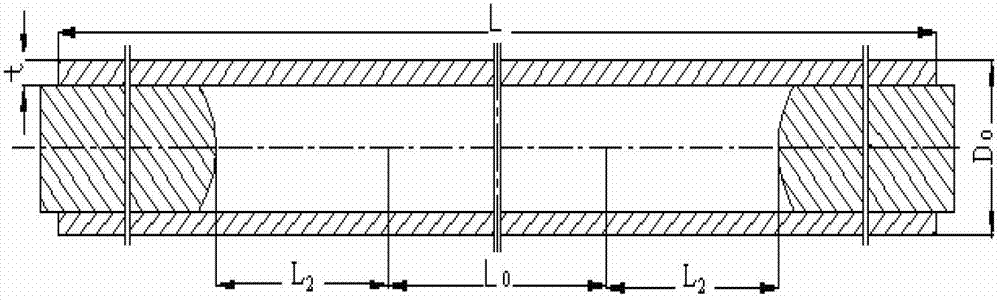

Abrasion-resistant ceramic elbow

InactiveUS20080169642A1Improve the immunityReduce brittlenessSemiconductor/solid-state device manufacturingBulk conveyorsShrinkage strainBrittleness

The invention discloses a spliced abrasion resistant ceramic elbow, wherein an abrasion resistant ceramic inner lining (4) is disposed on the inner surface of a seamless elbow body (1), and is formed by splicing a plurality of abrasion resistant ceramic tiles (2). The abrasion resistant ceramic tiles (2) are spliced along the circumferential direction to form an abrasion resistant ceramic ring (5) fitted with said seamless elbow body (1). A plurality of abrasion resistant ceramic rings (5) is connected along the axial direction to form an abrasion resistant ceramic inner lining (4) fitted with the seamless elbow body (1). The abrasion resistant ceramic elbow of the invention provides the advantages of good abrasion resistant capability, low brittleness and no shrinkage strain, simple structure, easy manufacture and assemble, low cost, and good reliability.

Owner:YANG CHANGGUI +2

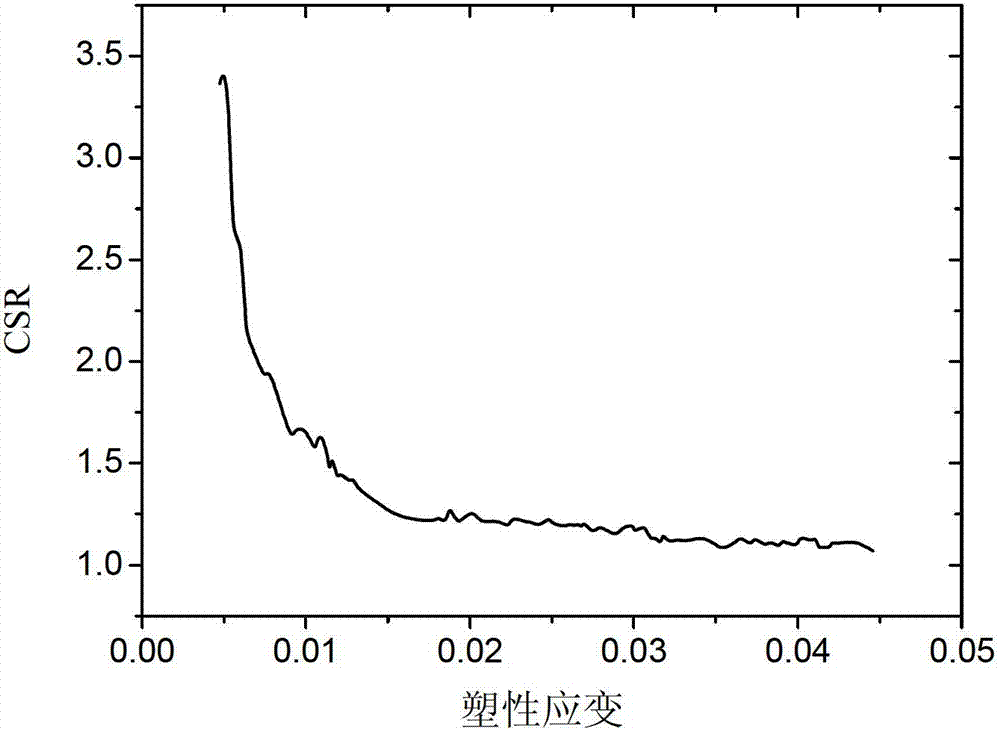

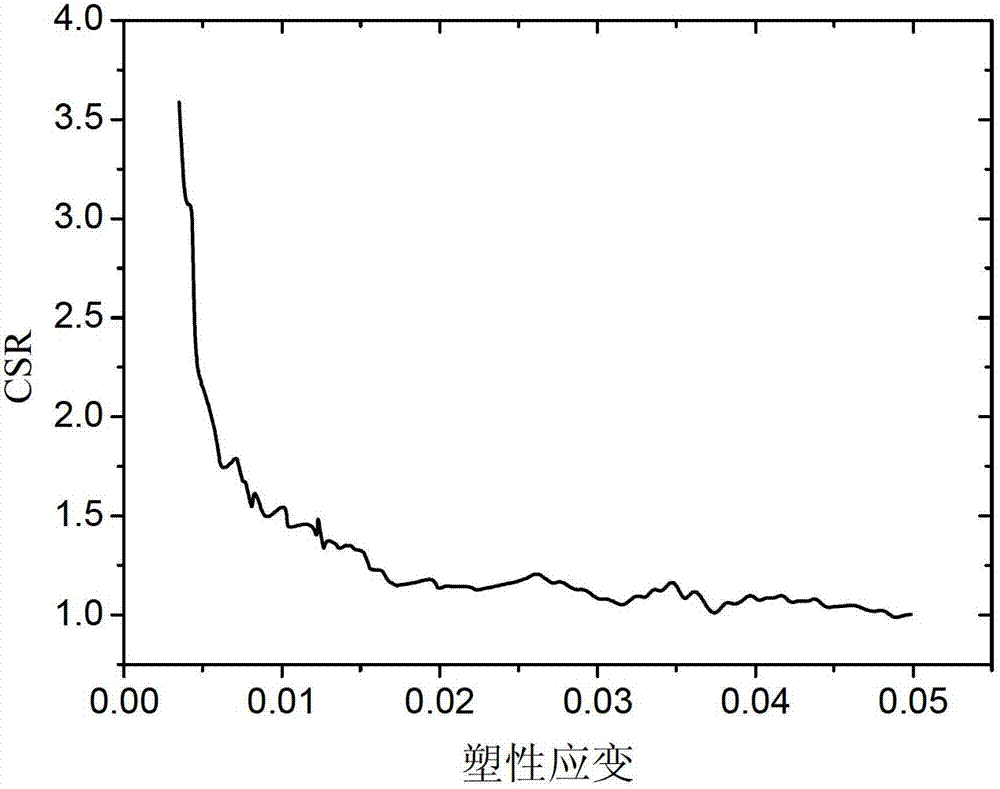

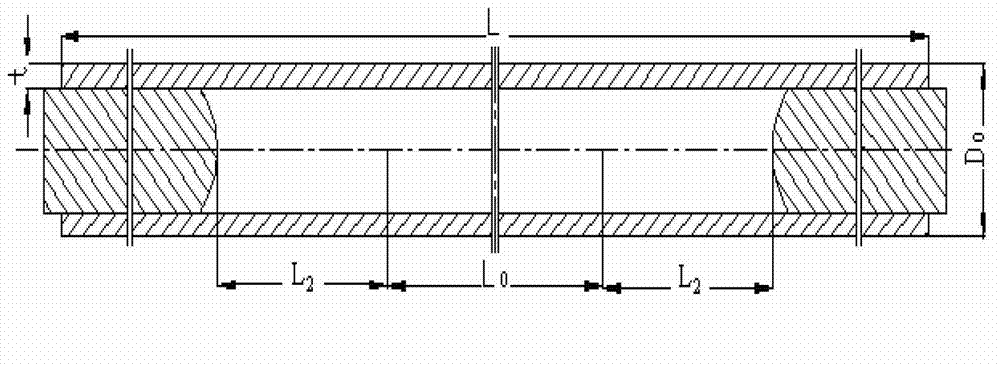

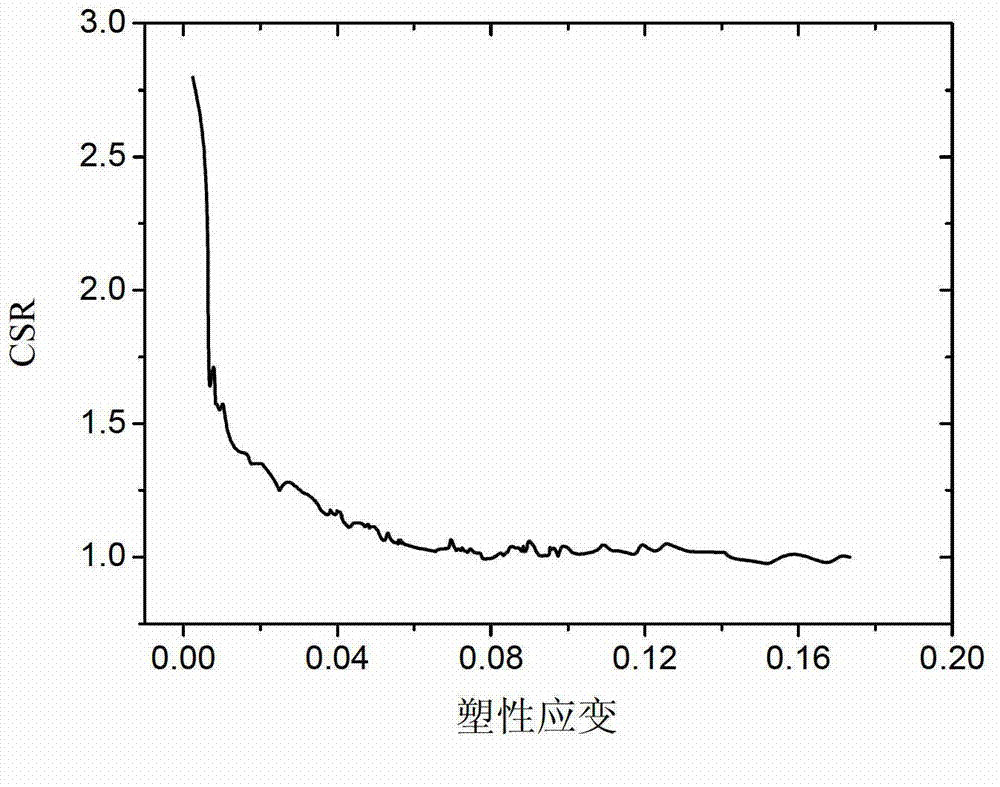

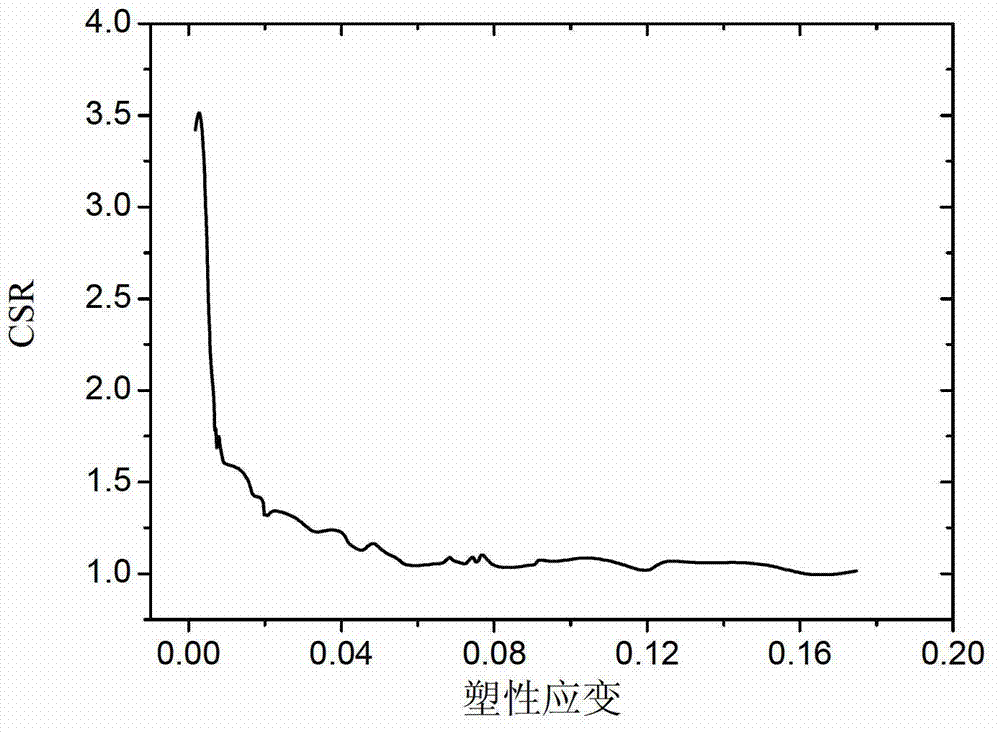

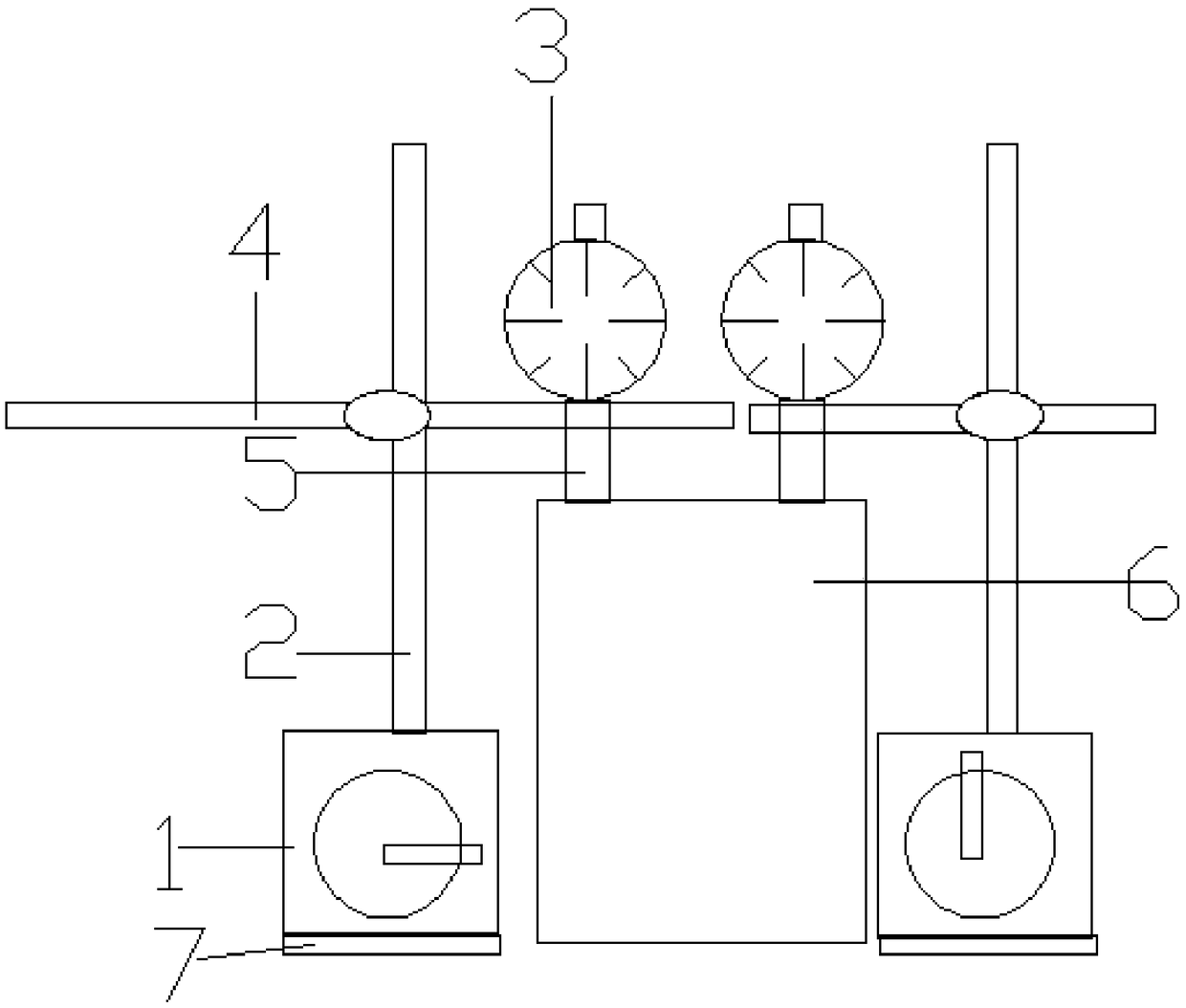

Method for continuously measuring change of shrinkage strain ratio of titanium alloy pipe

ActiveCN103091167AAccurately Obtain Shrinkage Strain RatioShrinkage strain ratio decreasesMaterial strength using tensile/compressive forcesNational standardShrinkage strain

The invention discloses a method for continuously measuring the change of shrinkage strain ratio of a titanium alloy pipe, which processes a pipe sample according to the size of a metal pipe sample in the national standard GB / T228-2002 and performs a stretching test at a set speed. In the stretching process, the changes of the outer diameter and axial scale distance of the pipe sample are accurately obtained through a transverse extensometer and a longitudinal extensometer respectively. The obtained outer diameter and axial scale distance of the pipe sample are corrected and substituted into a calculation formula of shrinkage strain ratio to obtain the changing shrinkage strain ratio. The method can effectively improve the accuracy of measuring the shrinkage strain ratio of a titanium alloy pipe. In the whole deformation process, the shrinkage strain ratio of the titanium alloy pipe is in a decreasing trend; at the initial stage of deformation of a pipe sample, the decreasing trend of the shrinkage strain ratio is obvious; the decreasing trend of the shrinkage strain ratio is gradually reduced in the following deformation; and the decreasing trend of the shrinkage strain ratio tends to be stable in subsequent deformation.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Sprayable laminate panel stiffener

InactiveUS20030211329A1Easy to changeElasticity be excessiveLiquid surface applicatorsSynthetic resin layered productsEngineeringRead through

A two-layer laminate panel stiffener is provided that may be constructed by spraying the individual layers onto substrates, such as, automotive body panels. The two-layer laminate panel stiffener reduces the amount of time and cost required for such reinforcing structures because it consists of only two layers and also because it can be sprayed (or extruded) onto the substrate. Spray application enables the laminate to be applied to any shape of substrate. The first layer is a soft, compliant layer of material (or precursor to such a material) that is sprayed (or extruded) onto the substrate. The second layer comprising a formulation capable of providing a rigid or toughened stiffener material once cured is then sprayed (or extruded) over the first layer. The two-layer laminate panel stiffener prevents oil-canning of the substrate, as well as paint read-through. When the material used to form the rigid layer cures, the compliant layer helps to shield the substrate from the strains resulting from the shrinkage of the rigid layer because the compliant layer is not rigid after cure. The second layer is rigid after cure but its shrinkage strains are blocked from getting to the substrate by the compliant layer.

Owner:HENKEL KGAA

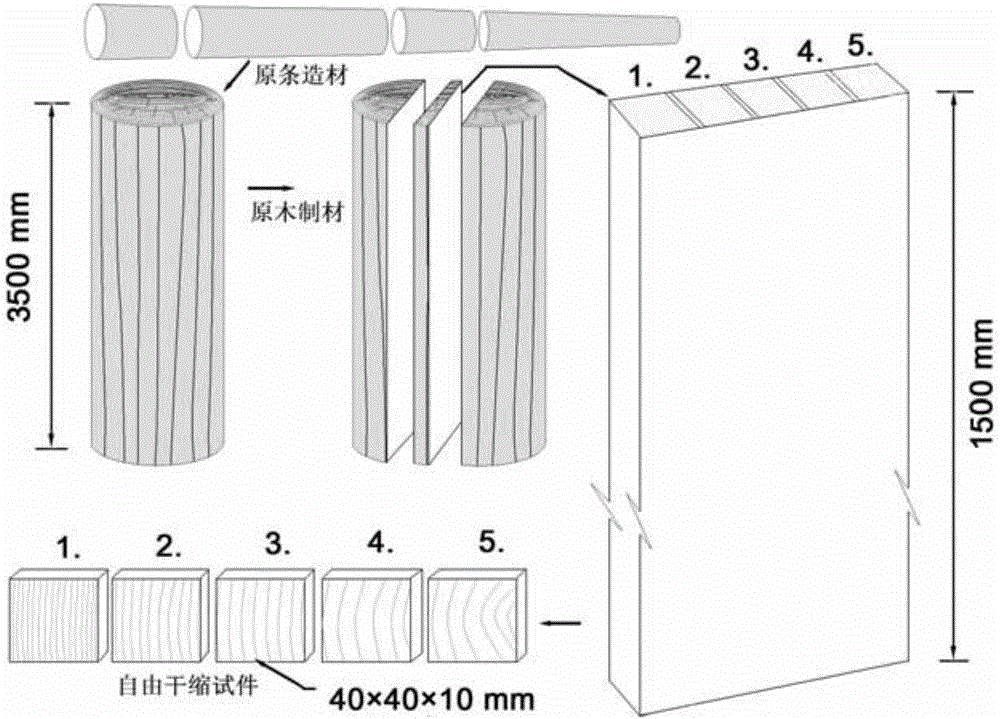

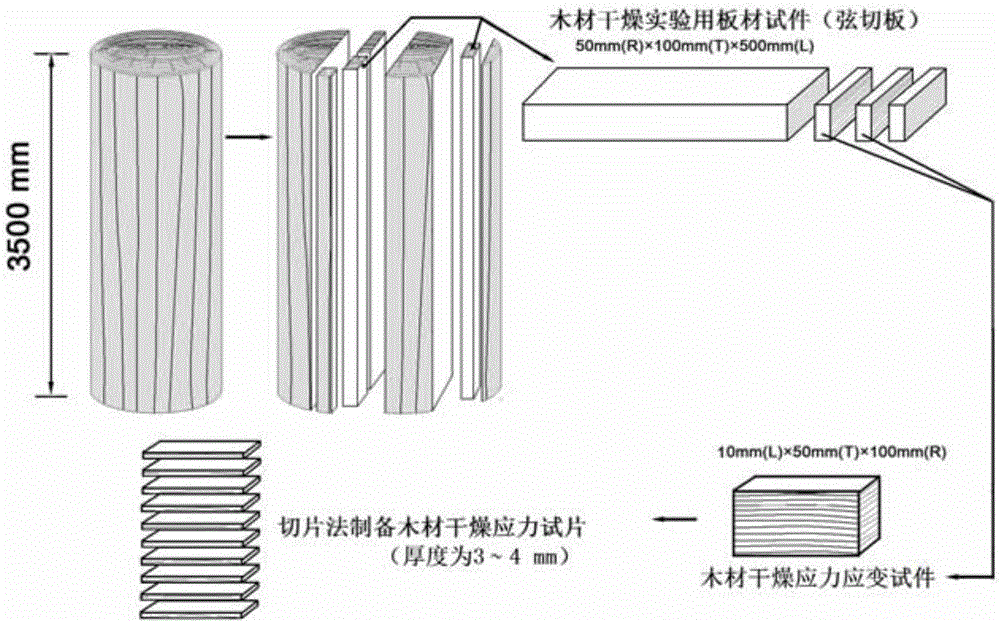

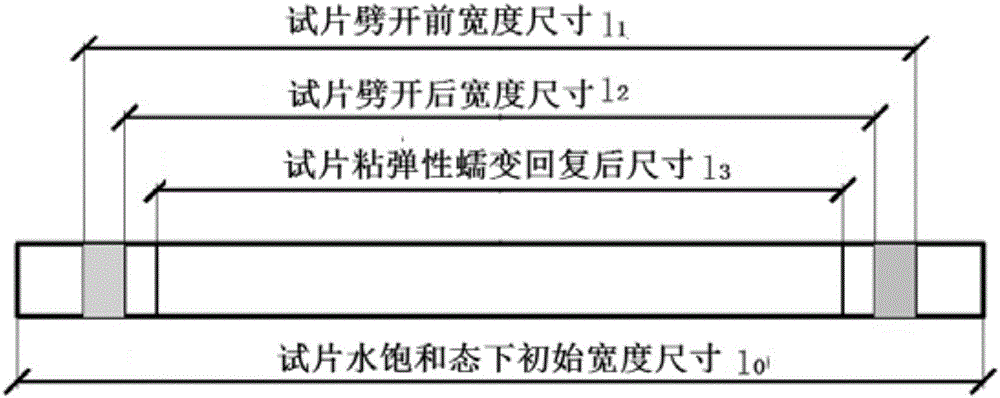

Sawn timber drying stress evaluating method for timber quality control

ActiveCN106225969AAchieve scientific evaluationOvercoming "Technical Ambiguity"Wood testingApparatus for force/torque/work measurementCreep strainAmbiguity

A sawn timber drying stress evaluating method for timber quality control is disclosed. The invention relates to a sawn timber drying stress evaluating method, and solves the problem that the drying stress and residual stress detection and analysis technology in a timber drying process in the prior art are low in precision, and that the purposes of controlling drying quality and shortening drying period can not be achieved. In order to test visco elastic creep along a sheet material width direction and free drying shrinkage strain of small dimension test pieces of same tree species under drying conditions, the mechano-sorptive creep strain along the sheet material width direction is calculated based on timber drying rheology principles. Timber drying mechano-sorptive creep gradient is defined, and affecting mechanism of timber mechano-sorptive creep gradient, timber water content gradient and other parameters on sheet material drying stress releasing process is determined. Technical ambiguity of describing timber drying stress by using conventional fork-tooth microtomy can be eliminated. The method is applicable to quantified description of coniferous wood drying stress, and scientific evaluation of timber drying quality is realized. The method is applied in the timber processing technical field.

Owner:NORTHEAST FORESTRY UNIVERSITY

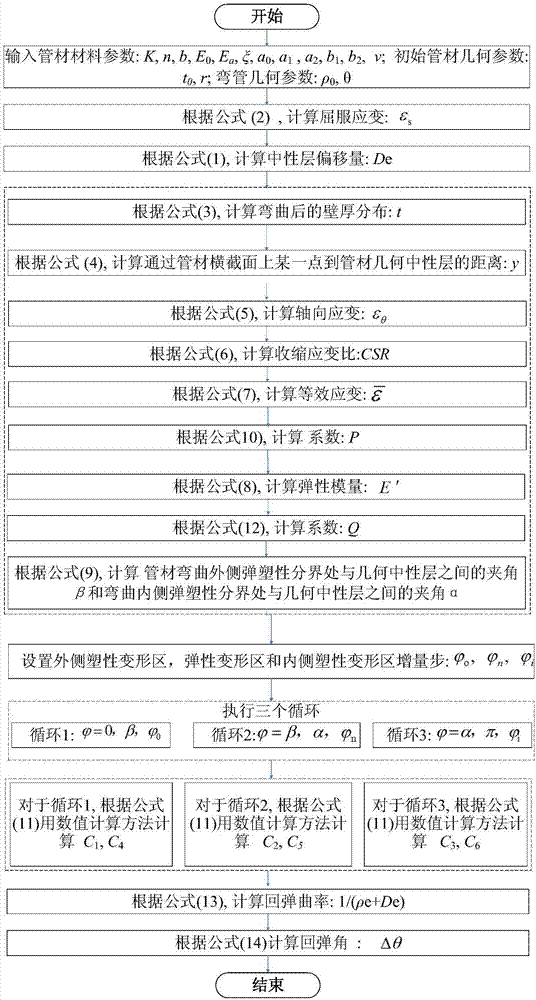

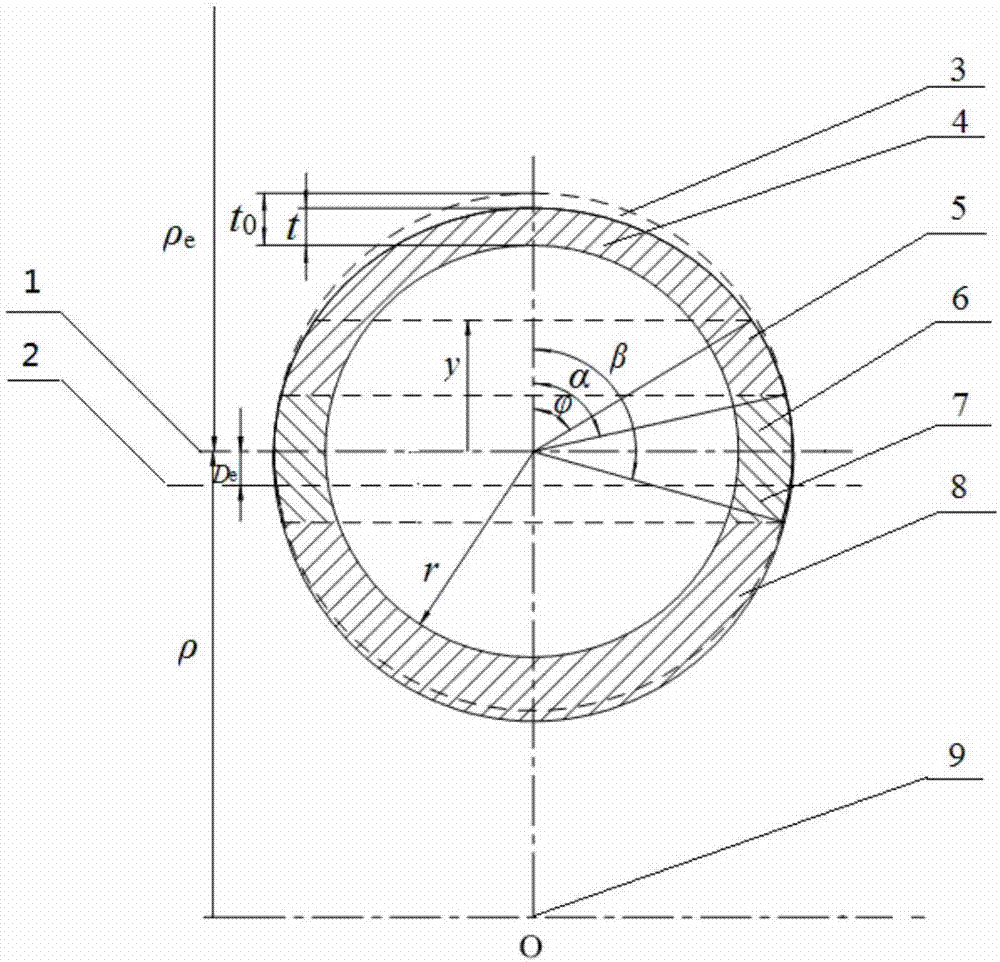

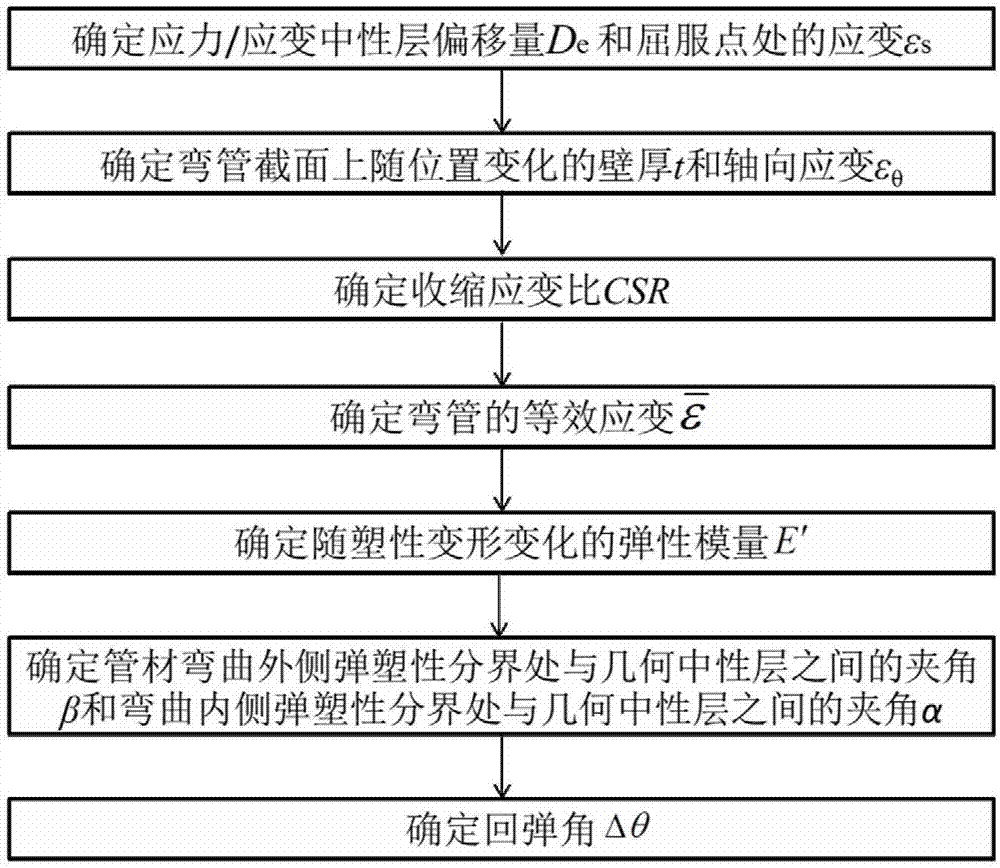

Method for determining numerical control bending springback angle of homogeneous pipe

InactiveCN106980717AImprove Springback Prediction AccuracyUniversalGeometric CADSpecial data processing applicationsNumerical controlEngineering

The invention discloses a method for determining a numerical control bending springback angle of a homogeneous pipe. Based on a Hill'48 anisotropic yield criterion and a static balance condition, a method for calculating bending springback of the homogeneous pipe by considering elastic modulus change and shrinkage strain ratio change is proposed, so that the springback prediction precision is improved and accurate control on pipe bending forming is realized. The method for calculating the bending springback of the homogeneous pipe by considering the elastic modulus change and the shrinkage strain ratio change in a pipe bending process is high in calculation speed, has a certain universality, can be used for preliminary prediction of the bending springback of the homogeneous pipe, and has an important guide effect for researching the influence of parameters on the springback.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

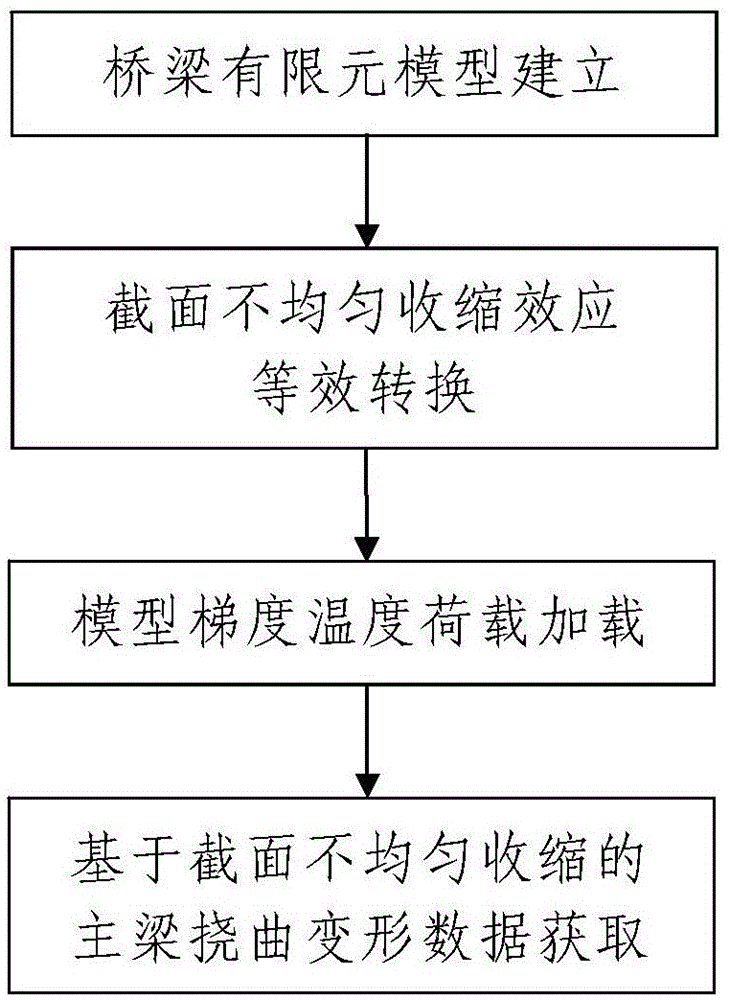

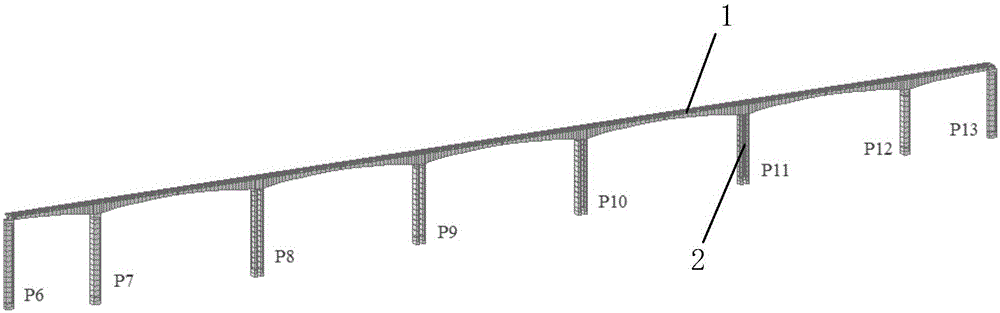

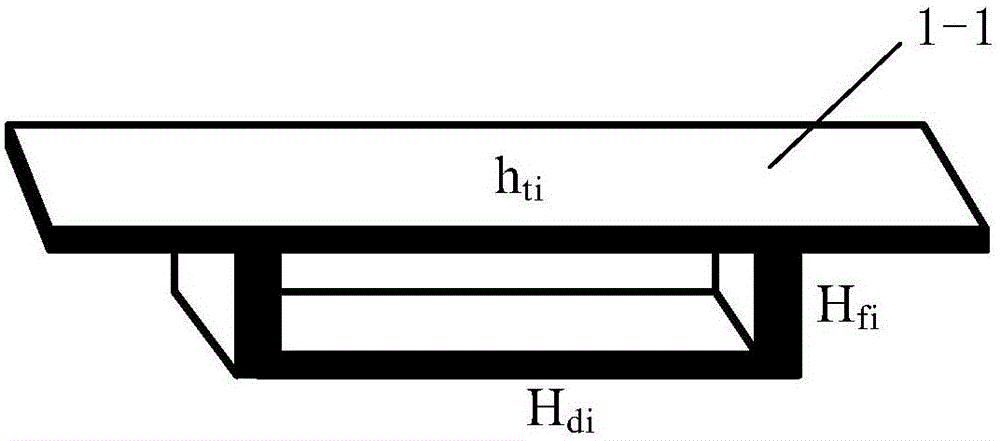

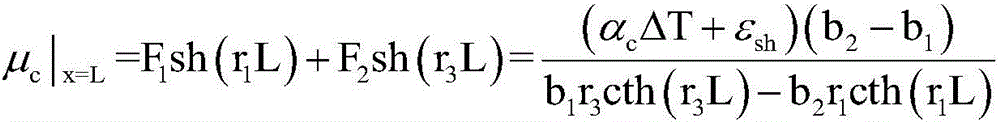

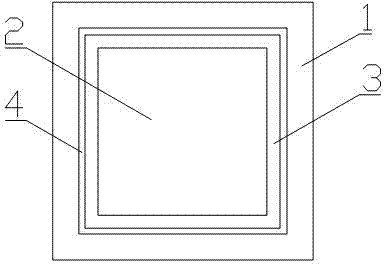

Section uneven shrinkage effect-based girder flexural deformation predicting method

InactiveCN105117510AThe method steps are simpleReasonable designSpecial data processing applicationsElement modelElement analysis

The invention discloses a section uneven shrinkage effect-based girder flexural deformation predicting method. The method comprises the following steps: I, establishment of a bridge finite element model: dividing a girder to be analyzed into N girder units, wherein the girder to be analyzed is a PC box girder; II, equivalent conversion of the section uneven shrinkage effect: respectively carrying out equivalent conversion on the section uneven shrinkage effect of each girder unit at a t moment to obtain the equivalent gradient temperature of each girder unit, wherein the equivalent conversion process comprises the selection of sections to be analyzed, the calculation of top plate shrinkage strain and bottom plate shrinkage strain and the calculation of the equivalent gradient temperature, and the equivalent gradient temperatures of N girder units form equivalent gradient temperature load information; III, loading of the model gradient temperature load; IV, obtaining of girder flexural deformation data on the basis of section uneven shrinkage. The method provided by the invention is simple in steps, reasonable in design and good in using effects; and a finite element analysis method is used to predict the girder flexural deformation by also considering the influence factors of the section uneven shrinkage, so that the prediction precision is high and the prediction is convenient to realize.

Owner:XIAN HIGHWAY INST

Tubeless diagonal tyre

The invention relates to a tubeless oblique crossing tire, comprising tyre foundation which comprises a tyre bead section. Tyre bead wires are arranged in inner of the tyre bead section. Bead fabric is arranged on rebate of the tyre bead section. Bead toe fabric is arranged on bead toe of the rebate and the bead fabric. An outside end of the bead toe fabric centre justifies to the tyre bead wires which in the innermost of the tyre foundation, and clings to an outside end of the toes of the bead fabric, and another end goes around and clings in the tyre foundations to extend into inner side of the tyre foundations. A masking adhesive tape which can fully cover the bead fabric and the bead toe fabric is arranged outside of the bead fabric and the bead toe fabric. The bead fabric generally is singles cloth and the bead toe fabric is canvas materiel. According to different tyre specifications, the bead fabric can be singles cloth of nylon, urethane elastic fiber, chinlon and polypropylene fiber, and the width of the bead toe fabric also selects out a suitable size according to tyre specification. Because the bead toe fabric clings to the outside of the singles cloth, the invention handles out the singles cloth shrinkage strain and knotting problems in process of vulcanization, and also improves air tightness of the tyre.

Owner:HAOHUA SOUTH CHINAGUILIN RUBBER

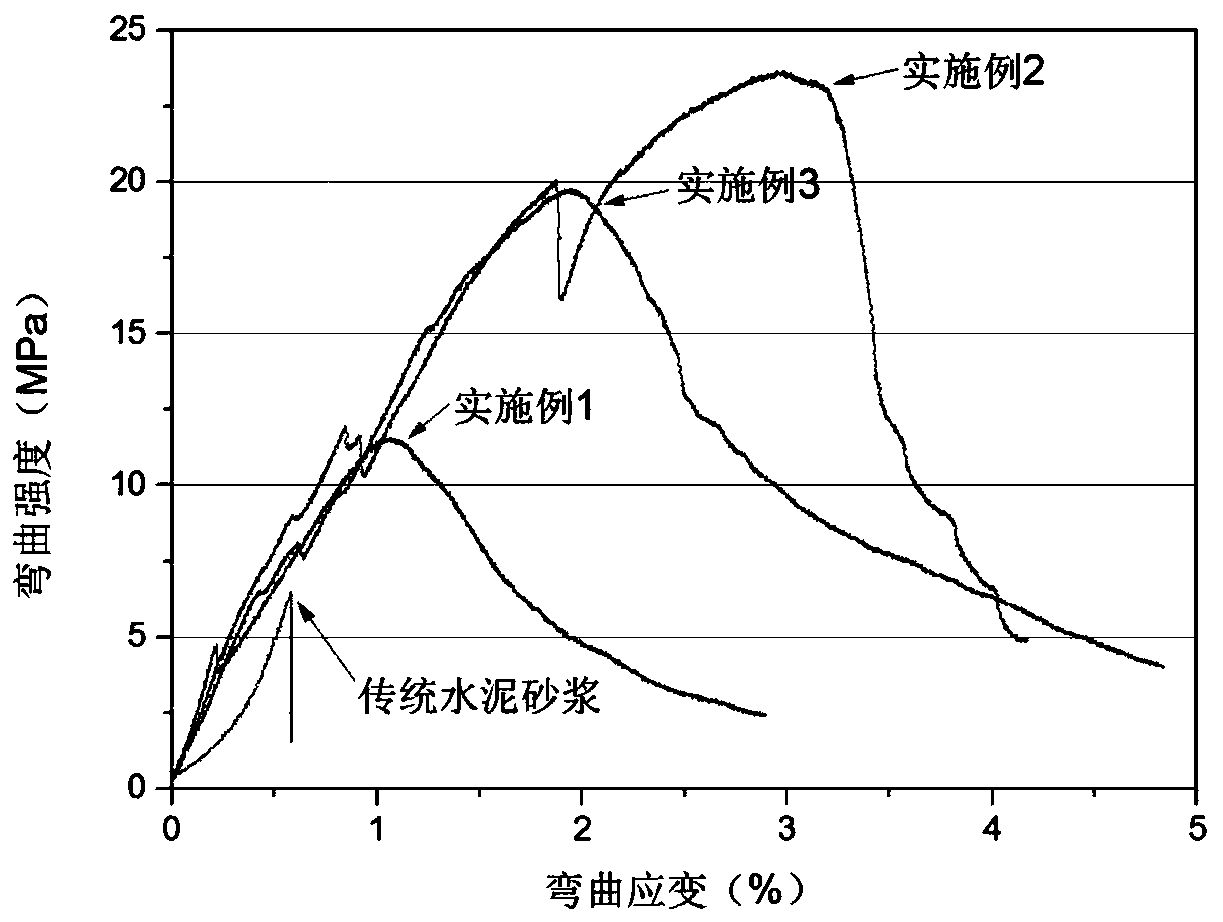

High-ductility concrete and preparation method thereof

The invention relates to high-ductility concrete. The high-ductility concrete comprises the following raw materials: a cementing material, an admixture, a fine aggregate, polyhedral oligomeric silsesquioxane modified polyvinyl alcohol fibers, an auxiliary agent and water, wherein the admixture comprises the reinforcing agent fly ash, silica fume and polytetrafluoroethylene micropowder. The ductility-increasing component of the high-ductility concrete is the polyhedral oligomeric silsesquioxane modified polyvinyl alcohol fibers; on one hand, a grafted modifier destroys partial intramolecular and intermolecular hydrogen bonds of the fibers in the aspect of structure, so the flexibility of the fibers is further enhanced, and a rigid cage-shaped structure is also beneficial to improving the breaking strength and compressive strength of the fibers; and on the other hand, the surface polarity of the grafted fibers is reduced, the adaptability of the grafted fibers to a concrete system is enhanced, the workability of mortar can be improved, hydration reaction is facilitated, and coagulation is promoted. The invention also finds that modified polyethylene fibers and the polytetrafluoroethylene micropowder have the effect of synergistically improving the shrinkage strain resistance of the concrete.

Owner:云浮市砼生新型材料有限公司

Method for obtaining shrinkage strain ratio in continuous change of titanium alloy tube

ActiveCN103115817AHigh precisionAccurately Obtain Shrinkage Strain RatioMaterial strength using tensile/compressive forcesCcd cameraTensile testing

The invention discloses a method for obtaining a shrinkage strain ratio in continuous change of a titanium alloy tube. A tube test sample is machined according to the size of a metal tube test sample in GB / T228-2002. A tensile test is carried out on a tensile test machine in a set tensile speed. The changes of the circumferential strain and the axial strain of the tube test sample in the tensile process are both precisely obtained through a CCD (Charge Coupled Device) camera. The circumferential strain and axial strain values of the tube test sample are precisely measured by using the camera in the one-way tensile process, and are subjected to elastic corrosion so as to accurately obtain the shrinkage stain ratio of the titanium alloy tube under a large plasticity deformation condition in the tensile process through formulas; and moreover the shrinkage strain ratio of the titanium alloy tube is decreased, that is, in the primary deformation period of the tube test sample, the shrinkage stain ratio is decreased dramatically, however, in later deformation, the decrease tendency of the shrinkage stain ratio is gradually reduced, and the decrease tendency of the shrinkage stain ratio in later deformation is gradually stable.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

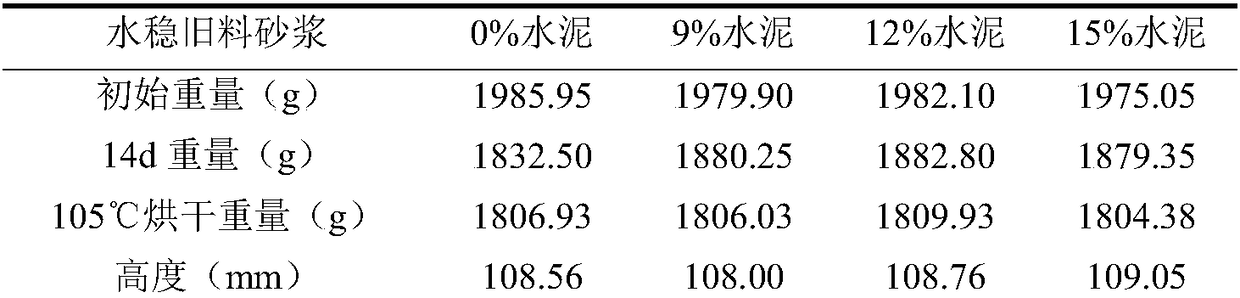

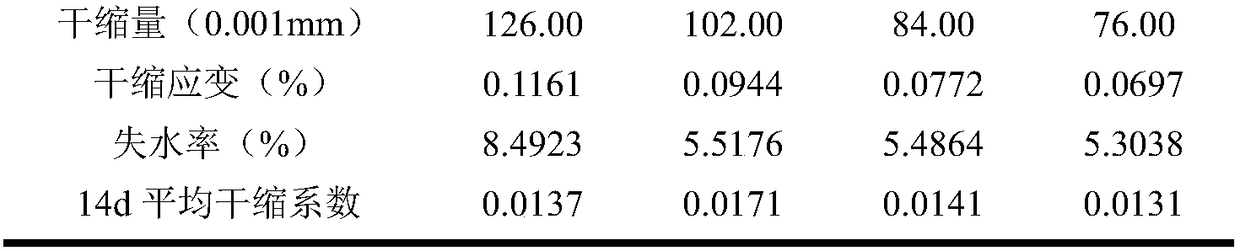

Method for determining dry shrinkage coefficient of cement stabilized macadam

The invention relates to a method for determining the dry shrinkage coefficient of cement stabilized macadam. The method comprises the following successive steps: step 1, determining the grading, optimum moisture content and maximum dry density of the cement stabilized macadam and determining the dosage of cement; step 2, calculating the dosage and water content of cement in a cement mortar test piece; step 3, making the test piece, and subjecting the shaped cement mortar test piece to maintenance; step 4, after completion of maintenance, placing the test piece in a dry shrinkage chamber to measure dry shrinkage amount and water loss rate; and step 5, calculating the dry shrinkage strain and dry shrinkage coefficient of the cement mortar test piece according to the measured water loss rateand dry shrinkage amount, and evaluating the dry shrinkage performance of the cement-stabilized graded macadam.

Owner:HENAN ZHONGYUAN EXPRESSWAY +1

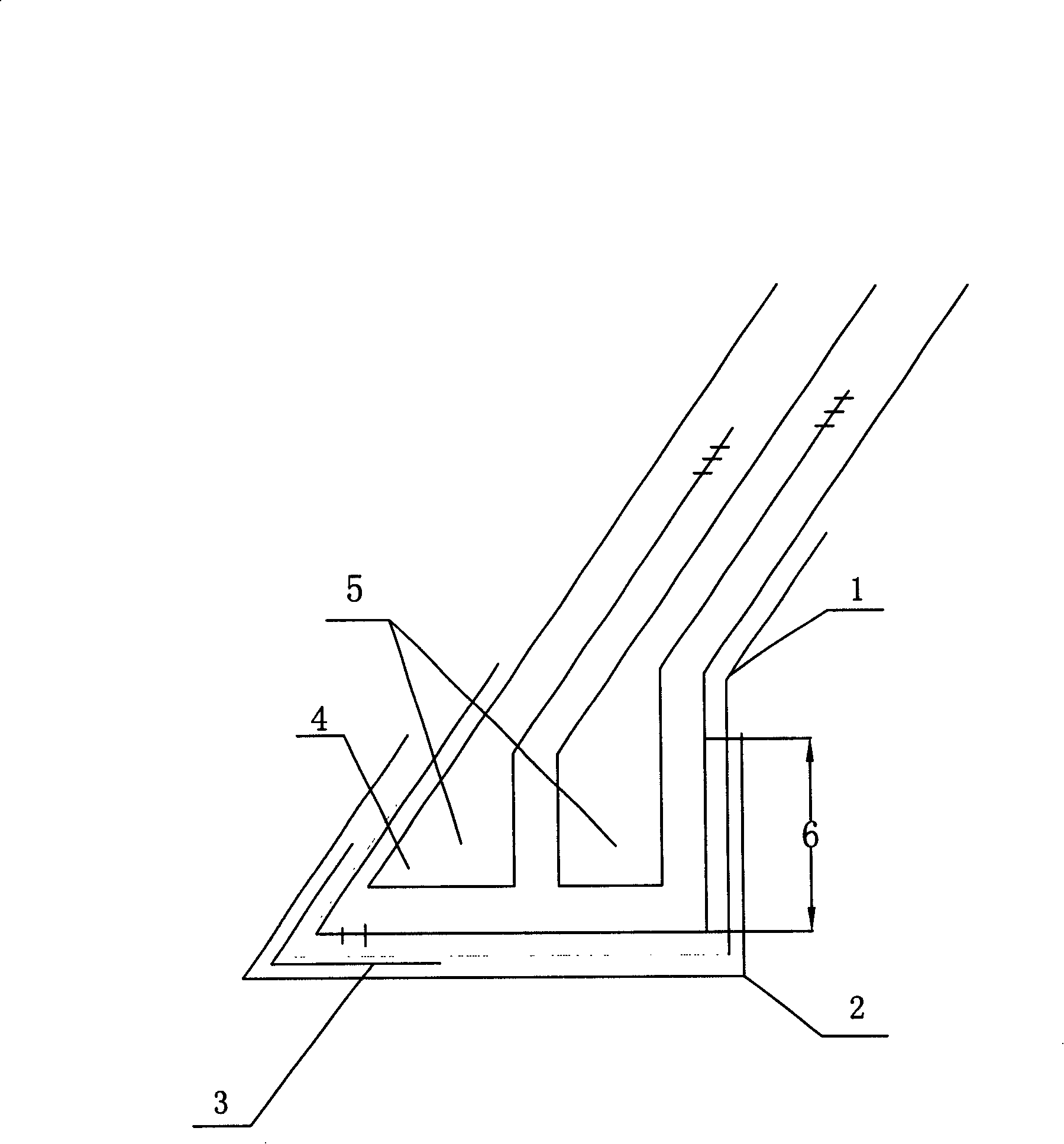

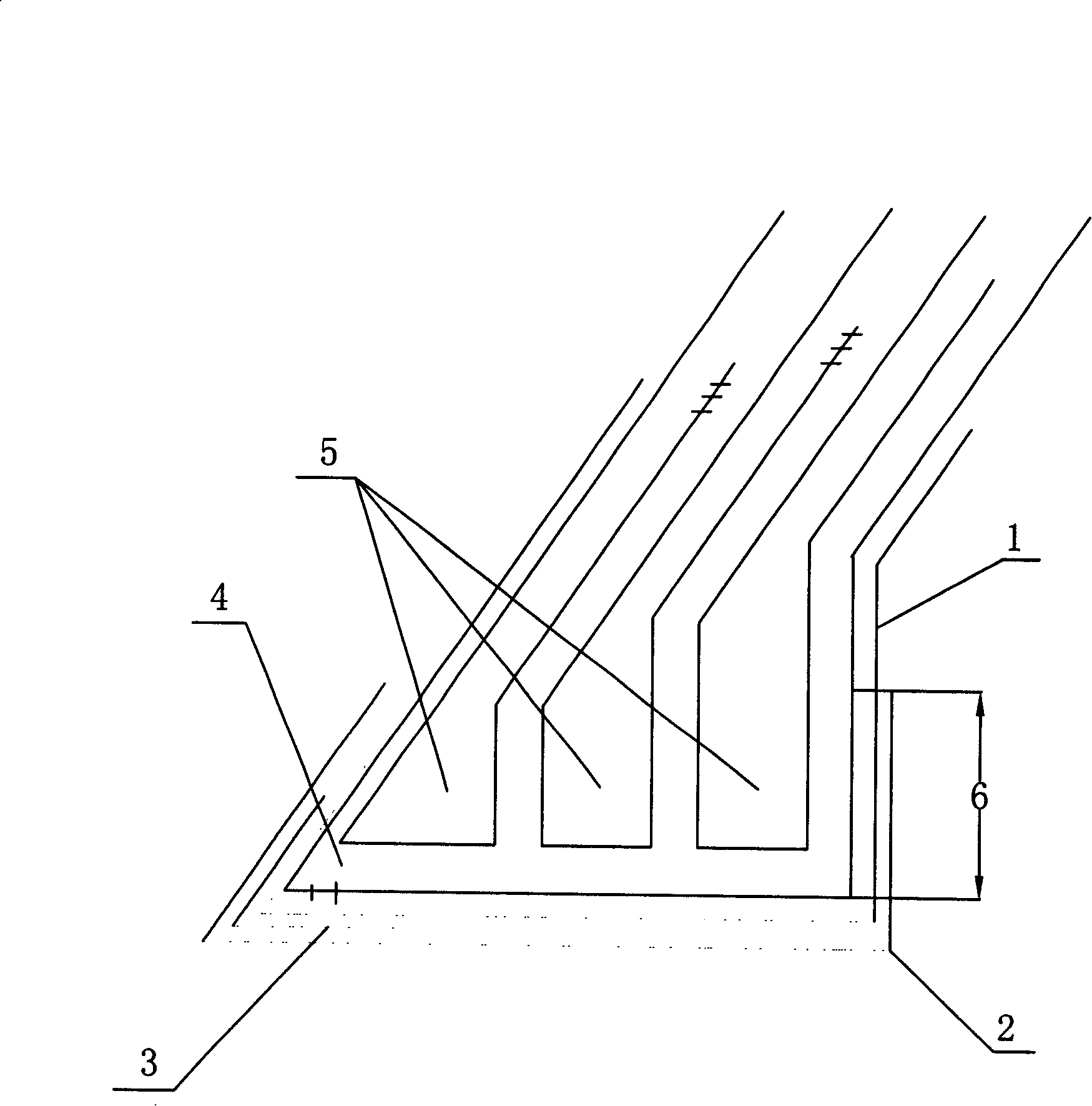

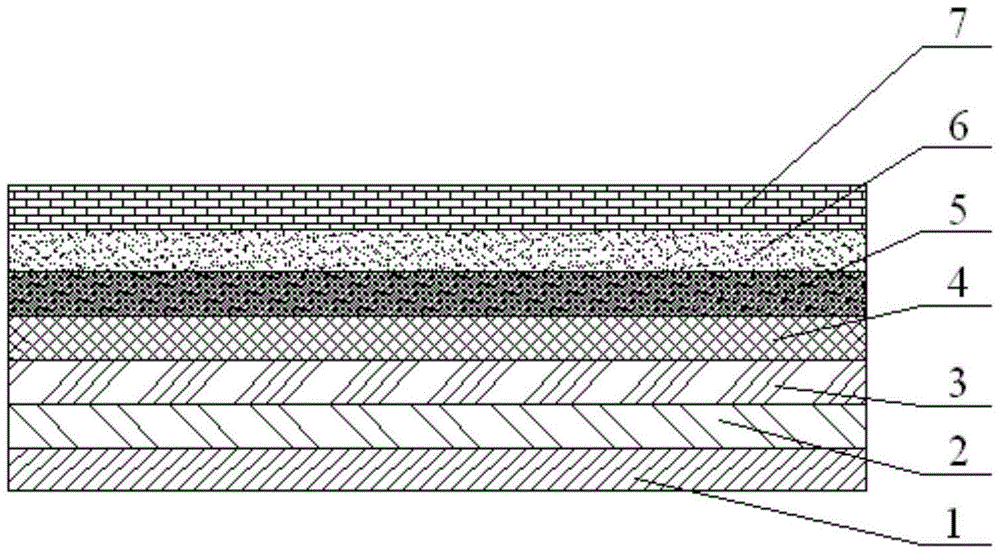

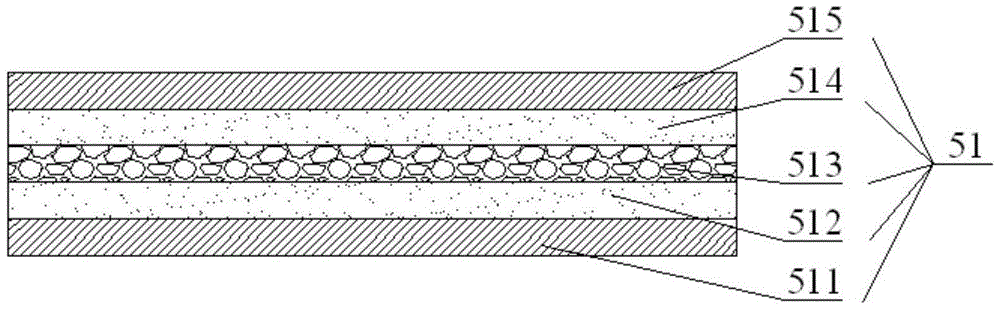

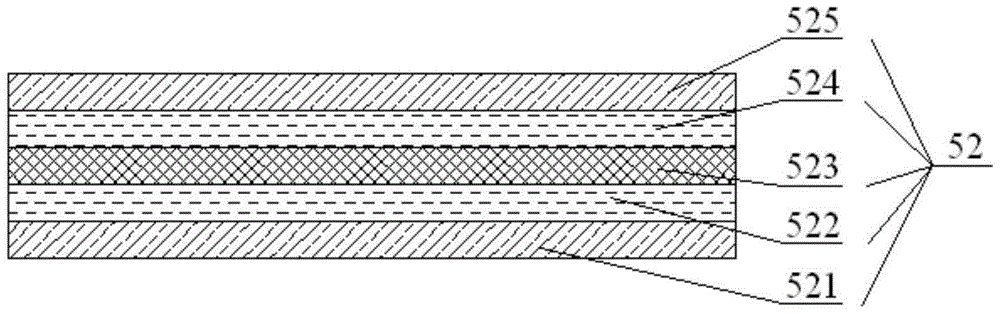

Root-resistant modified bitumen waterproof structure for planting roof

InactiveCN105201155ARetain propertiesTimely exclusionRoof covering using flexible materialsSynthetic resin layered productsWeather resistanceBituminous waterproofing

The invention provides a root-resistant modified bitumen waterproof structure for a planting roof. The waterproof structure includes a structural layer, a slope making layer, a heat preservation layer, a leveling layer, a root-resistant waterproof layer, a drainage layer and a filter layer, which are arranged from bottom to top; the root-resistant waterproof layer is made of modified bitumen waterproof rolling material; the modified bitumen waterproof rolling material is composite copper base modified bitumen waterproof rolling material or chemically root resistant type modified bitumen waterproof rolling material. The root-resistant modified bitumen waterproof structure for the planting roof, provided by the invention, has the dual functions of resisting water and preventing root penetration of the plant and the advantages of being root-resistant, tear-resistant, high in tensile strength and ductility, high in capability of adapting to base layer shrinkage strain and crack, and good in high and low temperature resistance, corrosion resistance, mildew resistance and weather resistance.

Owner:TIANJIN YUSHEN BUILDING WATERPROOF MATERIAL

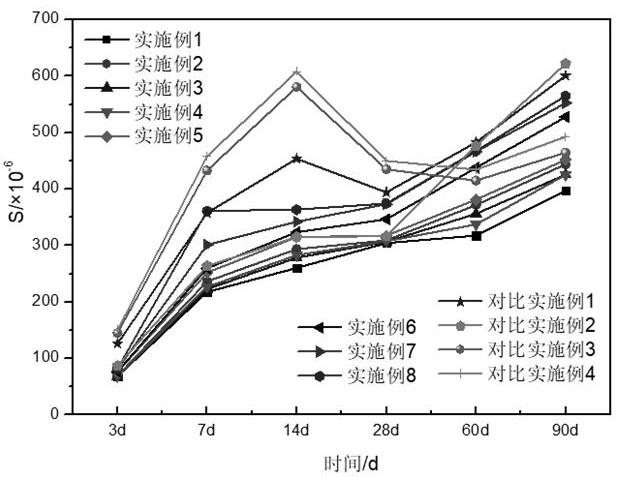

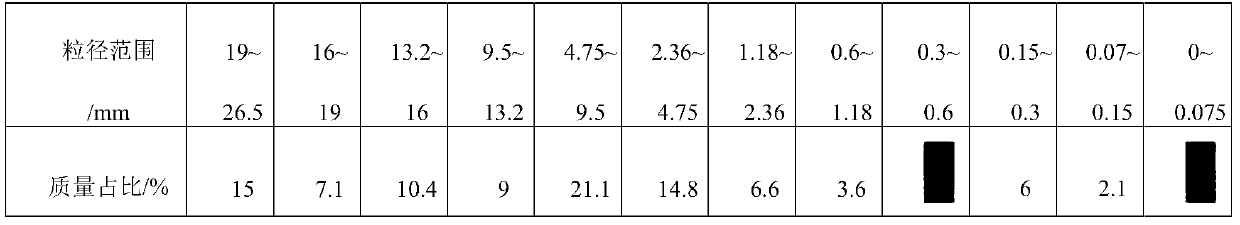

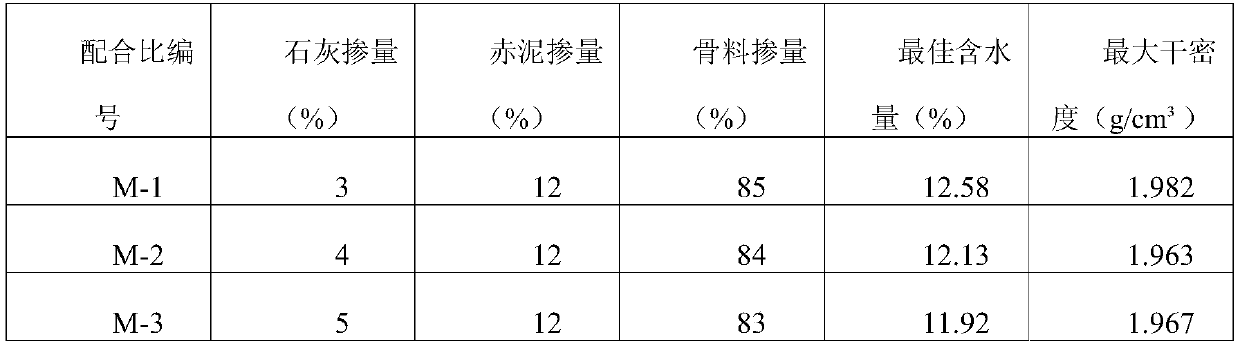

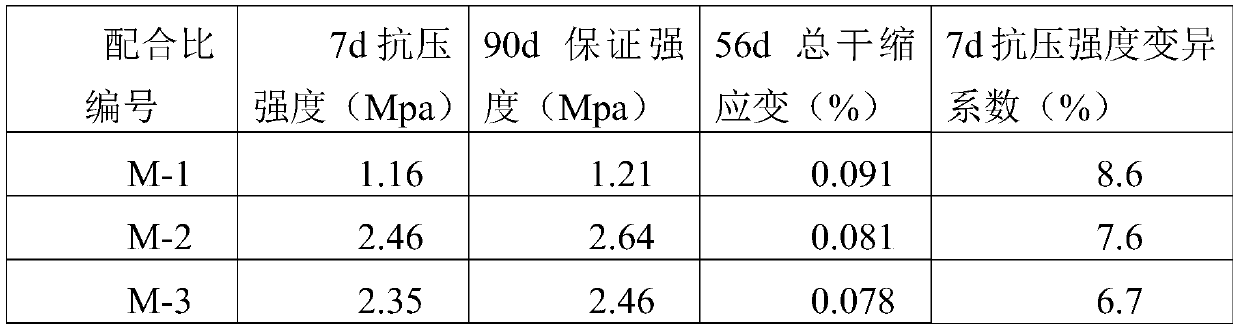

Road base material produced by stabilizing waste concrete construction waste aggregate with lime red mud

The invention discloses a road base material for stabilizing waste concrete construction waste aggregate with lime red mud, and belongs to the field of road engineering. Lime and red mud are used as inorganic binding materials, and the waste concrete construction waste aggregate is used as a stabilized material. A dry mixture comprises the components in percentage by weight: 3%-5% of lime, 12% ofred mud and 83-85% of waste concrete recycled aggregate. By adding water for mixing, the optimal water content of the compacted wet mixture is 11.92%-12.58%, and the maximum dry density of the compacted wet mixture is 1.963 g / cm<3>-1.982 g / cm<3>. The 7 d unconfined compressive strength of the base layer material is 1.16-2.46 MPa, the coefficient of variation is 6.7%-8.6%, and the 56 d total dry shrinkage strain is 0.078%-0.091%. Construction waste is fully recycled, use of natural gravel and lime is reduced, waste recycling is facilitated, and the problems of non-renewable resource shortage and environmental pollution are relieved.

Owner:BEIJING UNIV OF TECH

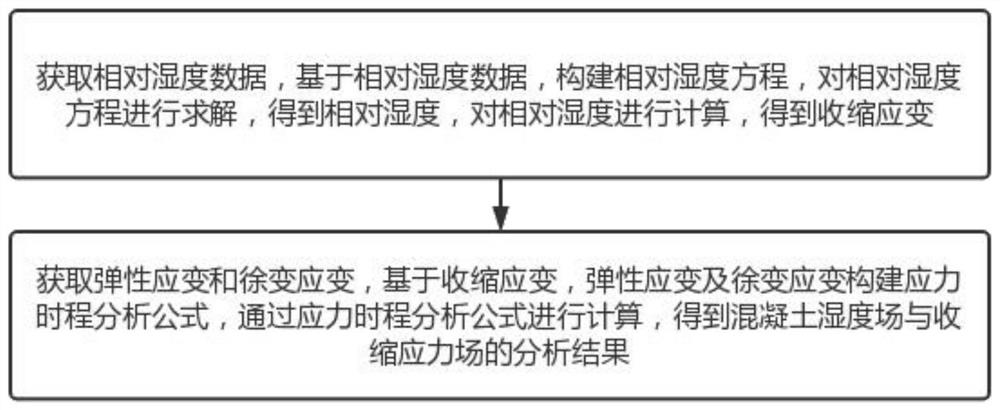

Method and system for analyzing humidity field and shrinkage stress field of concrete

PendingCN114091307AThe calculation result is accurateDesign optimisation/simulationSpecial data processing applicationsReinforced concreteCreep strain

The invention discloses a method and a system for analyzing a humidity field and a shrinkage stress field of concrete. The method comprises the following steps: acquiring relative humidity data, constructing a relative humidity equation based on the relative humidity data, solving the relative humidity equation to obtain relative humidity, and calculating the relative humidity to obtain shrinkage strain. acquiring elastic strain and creep strain, creating a stress time-history analysis formula based on the shrinkage strain, the elastic strain and the creep strain, calculating the stress time-history analysis formula to acquire analysis results of the concrete humidity field and the shrinkage stress field. The coupling relation between the relative humidity and the shrinkage strain is fully considered, and finally, the stress of the reinforced concrete structure under the shrinkage action is accurately analyzed on the premise of the creep action.

Owner:HUITONG ROAD & BRIDGE CONSTR GROUP

Prefabrication cast-in-place concrete floor

The invention belongs to a prefabrication cast-in-situ concrete slab, which comprises the following compositions by weight portion: 290 to 360 portions of ordinary portland cement, 72 to 90 portions of fly ash, 8 to 10 portions of additive, 740 to 820 portions of sand, 900 to 1,100 portions of stones and 170 to 230 portions of water. The invention provides a prefabrication cast-in-situ concrete slab having the advantages of small shrinkage strain, strong cracking resistance and short curing time.

Owner:刘期亮

Green cement-based composite material with low shrinkage and high ductility

The invention discloses a green cement-based composite material with low shrinkage and high ductility, and the green cement-based composite material mainly comprises cement, fly ash, industrial wasteresidue, metakaolin, machine-made sand, hydrophilic polyvinyl alcohol fiber, additives and water. According to the invention, the green cement-based composite material with shrinkage strain less than1050 mu epsilon, compressive strength greater than 45mpa and flexural strength greater than 10 MPa is prepared by optimizing the basic mixture ratio.

Owner:ZHEJIANG UNIV

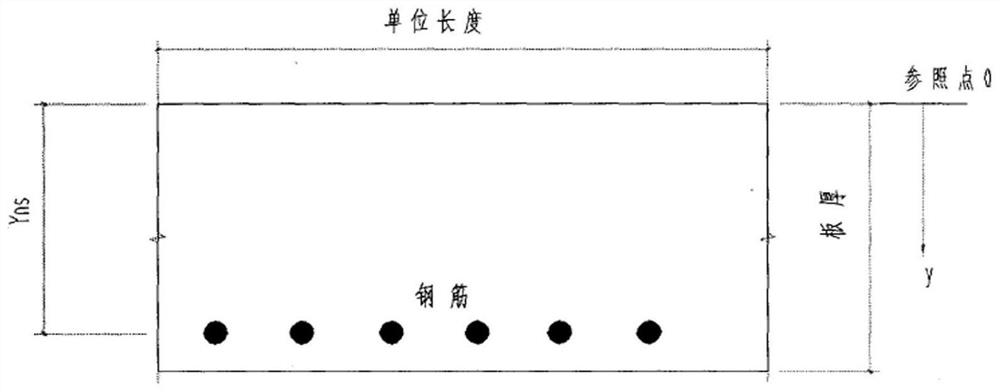

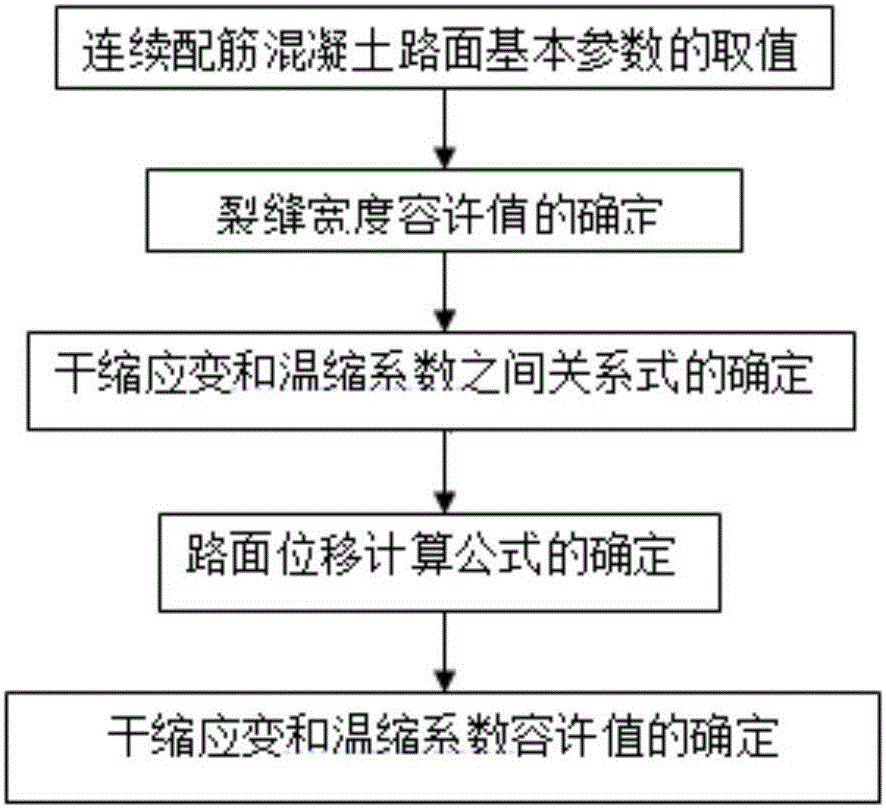

Method for determining allowable value of dry shrinkage strain and temperature shrinkage coefficient of continuous reinforcement concrete

InactiveCN105862540AReduce crack widthSimple stepsPaving reinforcementsIn situ pavingsRoad surfaceShrinkage strain

The invention discloses a method for determining allowable values of a dry shrinkage strain and a temperature shrinkage coefficient of continuous reinforcement concrete. The allowable values of the dry shrinkage strain and the temperature shrinkage coefficient are calculated based on a continuous reinforcement concrete pavement displacement calculation formula and a relation between the dry shrinkage strain and the temperature shrinkage coefficient, and a blank in the method for determining the dry shrinkage strain and the temperature shrinkage coefficient of the continuous reinforcement concrete at present is filled. After the allowable values of the dry shrinkage strain and the temperature shrinkage coefficient are determined, the allowable values can be used for guiding the structural design of the continuous reinforcement concrete pavement and the component design of concrete materials, the crack width of the continuous reinforcement concrete can be guaranteed to be smaller than the allowable value and thus the thrust of the continuous reinforcement concrete pavement is controlled. The method for determining the dry shrinkage strain and the temperature shrinkage coefficient of the continuous reinforcement concrete has the advantages of simple step, definite formula, clear thought and higher calculation accuracy.

Owner:CHANGAN UNIV

Production technology for coated glass fiber gridding cloth

InactiveCN109111865AImprove adhesionGood alkali resistanceNon-macromolecular adhesive additivesFilm/foil adhesivesGlass fiberFiberglass mesh

The invention discloses a production technology for coated glass fiber gridding cloth. The production technology comprises the following steps: weighing raw material for standby use according to a formula; stirring raw materials by a stirrer to enable raw materials and auxiliary materials to be evenly mixed; then, through a vacuum material suction device, continuously conveying mixed raw materialsto a screw extruder; after the raw materials are molten and compressed by the screw extruder, forming fusant of a viscous state, and then, conveying to a fusant filter through a fusant pipeline to befiltered; sending the fusant into a metering pump, controlling by the metering pump to be sent into a spinning box body, carrying out a spinning operation to obtain a silk bundle, and carrying out airflow traction on the silk bundle to form a fiber network blank. The coated glass fiber gridding cloth has the advantages of good alkali resistance, flexibility and warp and weft direction height tensile resistance, good chemical stability, alkali resistance, cement etching resistance, other chemical corrosion resistance, high strength, high modulus, light weight, good size stability, stiffness, flatness, small possibility of shrinkage strain and good positioning performance.

Owner:合肥神舟建筑集团有限公司

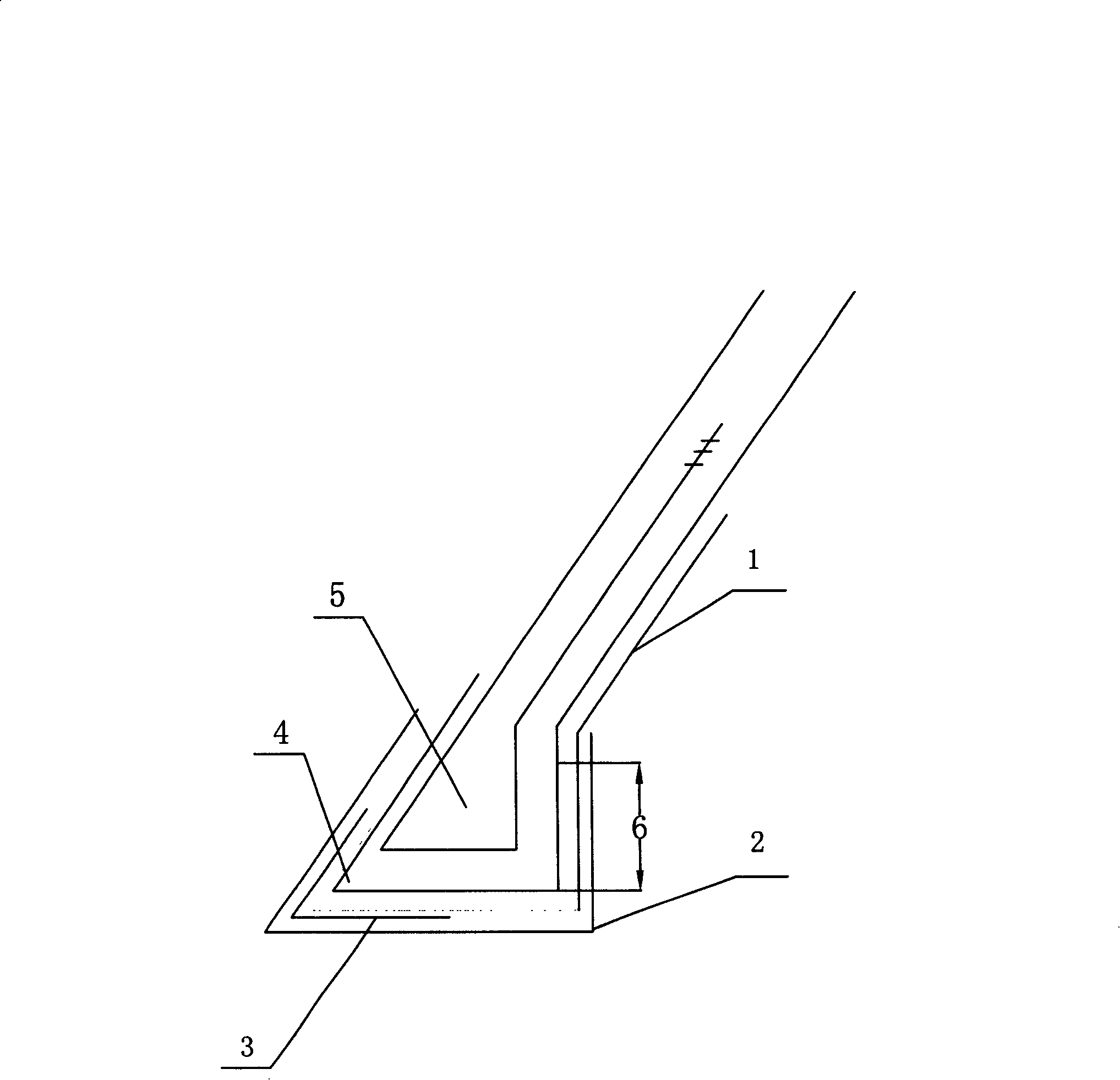

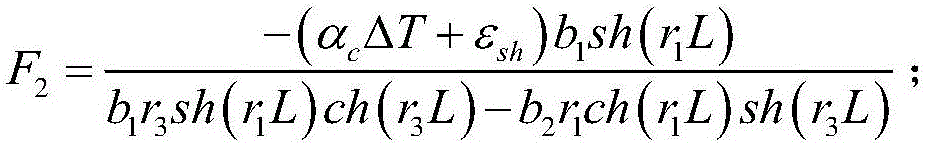

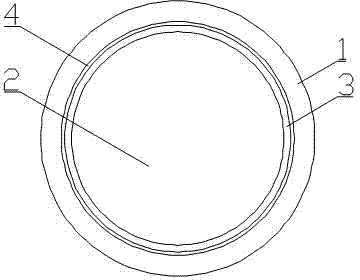

Concrete filled steel tube capable of preventing stripping damage

InactiveCN104120833AReduce shrinkage strainDoes not affect liquidityStrutsPillarsAdhesiveShrinkage strain

The invention discloses a concrete filled steel tube capable of preventing stripping damage. The concrete filled steel tube comprises a steel tube (1) and concrete (2), wherein a geotechnical cloth layer (3) is arranged between the steel tube (1) and the concrete (2); the geotechnical cloth layer (3) is arranged close to the inner wall of the steel tube (1) and connected with the inner wall of the steel tube (1) through structural adhesive (4). The concrete filled steel tube capable of preventing the stripping damage has the advantages that geotechnical cloth high in tensile strength is selected for restraining boundary concrete in the concrete filled steel tube, so that the shrinkage strain of the boundary concrete is reduced, and the fluidity of the dense concrete is not influenced; the geotechnical cloth is closely adhered to the inner wall of the steel tube; the elastic deformation is generated in the presence of the shrinkage strain of the boundary concrete, so that the stripping damage to the concrete filled steel tube is avoided, and the stability and the anti-seismic property of the concrete filled steel tube are improved.

Owner:WUHAN UNIV

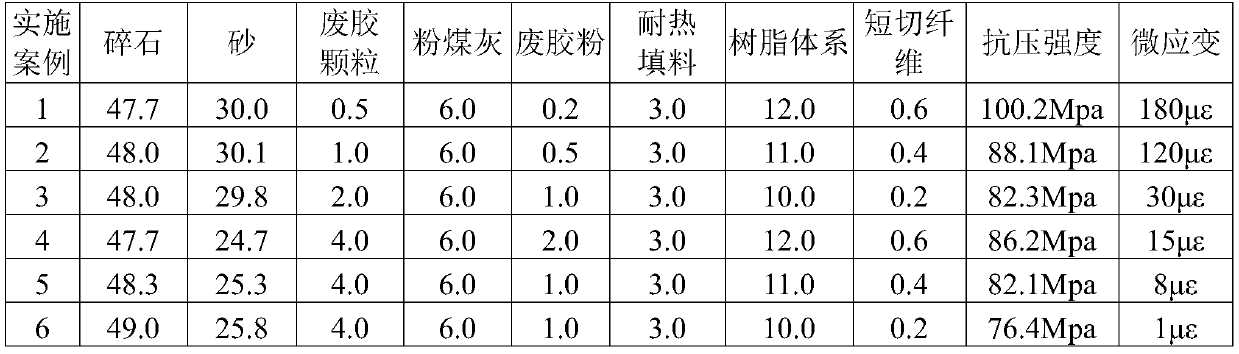

Low-shrinkage, high-corrosion-resistance and high-strength resin concrete and preparation method thereof

ActiveCN110746140AExtend curing timeReduce shrinkage strainSolid waste managementFiberEnergy absorption

The invention provides a low-shrinkage, high-corrosion-resistance and high-strength resin concrete and a preparation method thereof. The concrete comprises 8.0-15.0% of a resin system, 45.0-52.0% of gravels, 20.0-36.0% of sand, 3.0-8.0% of fly ash, 0.5-10.0% of waste rubber particles, 0.2-2.0% of waste rubber powder and 0.1-6.0% of chopped fibers. The waste rubber particles and the waste rubber powder are added to reduce early curing shrinkage of the resin concrete; and the curing time of resin in the resin concrete is prolonged, the stress relaxation of the resin concrete is increased, the shrinkage strain of the concrete under a constraint condition is reduced, the early-stage non-load crack of the resin concrete is avoided, the vibration resistance and the energy absorption property ofthe resin concrete are improved, the problem of volume instability caused by large early curing shrinkage of the resin concrete is solved, large-area and large-volume pouring of the resin concrete inengineering can be achieved, and the resin concrete can be applied to engineering with high requirements for water resistance, corrosion resistance and durability, such as swimming pool walls and sewage treatment pools, and engineering needing vibration resistance, such as machine tool foundations, to replace cement concrete.

Owner:HARBIN ENG UNIV

GRC board based on steel slag carbonization

The invention belongs to the technical field of construction materials, and particularly relates to a GRC board based on steel slag carbonization. The GRC board is prepared from the following raw materials in parts by volume: 40-45 parts of steel slags, 40-50 parts of quartz sands, 2-6 parts of glass fibers and 5-10 parts of water. The matrix is formed from steel slag by carbonizing and hardening,and is transformed into a matrix with gelling performance and excellent mechanical performance by a steel slag carbonizing process, and the inert quartz sands and glass fibers are uniformly dispersedinside the matrix; furthermore, the production cost can be reduced by using conventional medium-alkaline glass fibers due to the fact that the specific low alkaline environment of the carbonized matrix has low requirement for alkali resistance on glass fibers; the GRC board has extremely low volume shrinkage strain and high volume stability; and the GRC board based on steel slag carbonization hasexcellent mechanical performance, high durability, low cost and high environmental friendliness, and the preparation method has the advantages of simple and controllable process, short preparation cycle and the like.

Owner:WUHAN UNIV OF TECH

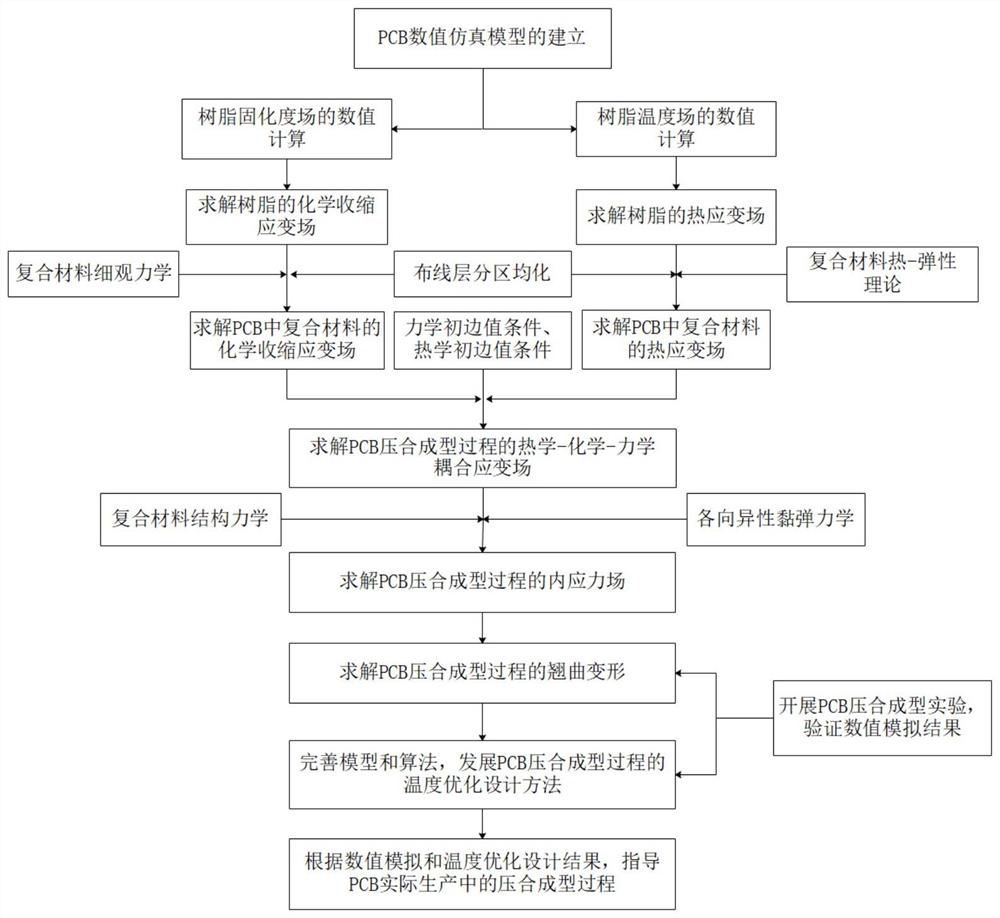

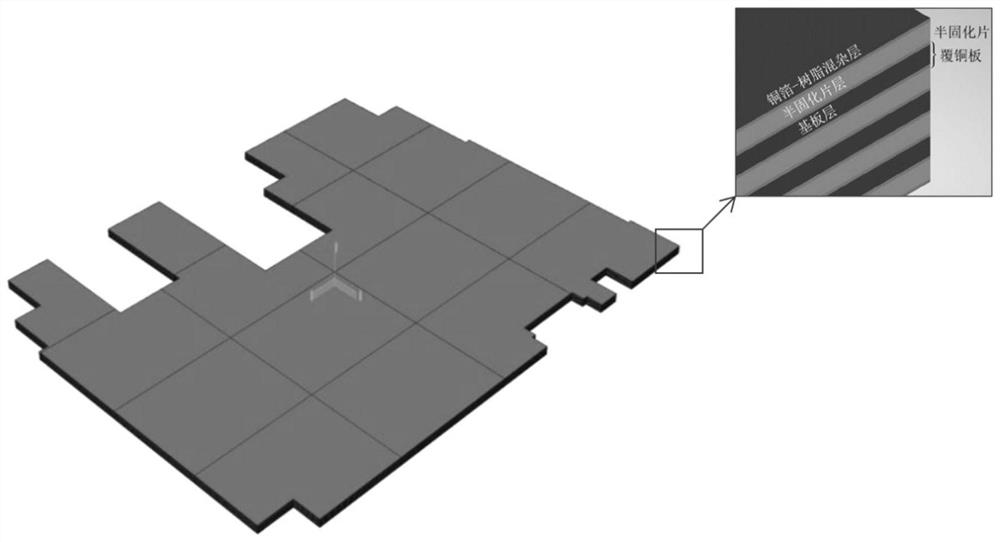

Temperature optimization design method and system for reducing buckling deformation of PCB after lamination

ActiveCN114189999ASolve the problem caused by the amount of warping deformationReduce warpagePrinted circuits stress/warp reductionDesign optimisation/simulationThermodynamicsProcess engineering

The invention discloses a temperature optimization design method and system for reducing buckling deformation of a PCB after lamination, and the method comprises the steps: carrying out the layering modeling of the PCB, carrying out the partitioning of a mixed layer, and defining an equivalent material performance parameter in each region; calculating a temperature field and a curing degree field of resin in the PCB; determining the highest curing temperature of the PCB in the thermocompression bonding stage; obtaining a thermal strain field and a chemical shrinkage strain field of the composite material in the PCB based on the temperature field and the curing degree field; numerical simulation of PCB press-fit forming is carried out, and the buckling deformation amount of the PCB at the highest curing temperature is obtained; and changing the maximum curing temperature of the PCB in the press-fit forming numerical simulation process to obtain the buckling deformation of the PCB after press-fit forming at different maximum curing temperatures, and finally selecting the maximum curing temperature which enables the buckling deformation to be minimum. According to the invention, the problem caused by reducing the buckling deformation in the PCB press-fit forming process in the prior art is solved.

Owner:SHANDONG UNIV

Low-contraction, high-temperature-resistant, and high-strength resin concrete and preparation method thereof

The invention provides a low-contraction, high-temperature-resistant, and high-strength resin concrete and a preparation method thereof. The resin concrete comprises following components in percentageby weight: 8.0 to 15.0% of a resin system, 45.0% to 51.0% of broken stone, 20.0 to 38.0% of sand, 2.0 to 7.0% of fly ash, 0.5 to 3.0% of a heatproof filling material, 0.0 to 5.0% of waste rubber particles, 0.2 to 2.0% of waste rubber powder, and 0.1 to 6.0% of chopped fibers. By adding waste rubber particles and waste rubber powder, the curing and contraction of the resin concrete in the early stage are prevented; the curing time of resin in the resin concrete is prolonged; the stress relaxation of the resin concrete is improved; under a constraint condition, the contraction strain of concrete is reduced, and the non-loaded cracks of the resin concrete are prevented in the early stage. The vibration-resistant performance and energy-absorbing performance of the resin concrete are improved.The problem of unstable volume due to the large curing-shrinkage of the resin concrete in the early stage is solved. Large-scale and large-volume casting of the resin concrete in a project can be realized. The resin concrete can replace cement concrete in some engineering projects, which have high requirements on high temperature resistant performance, waterproof performance, corrosion resistantperformance, and durability, such as desulfurization towers, high temperature chemical liquid ponds, and the like.

Owner:HARBIN ENG UNIV

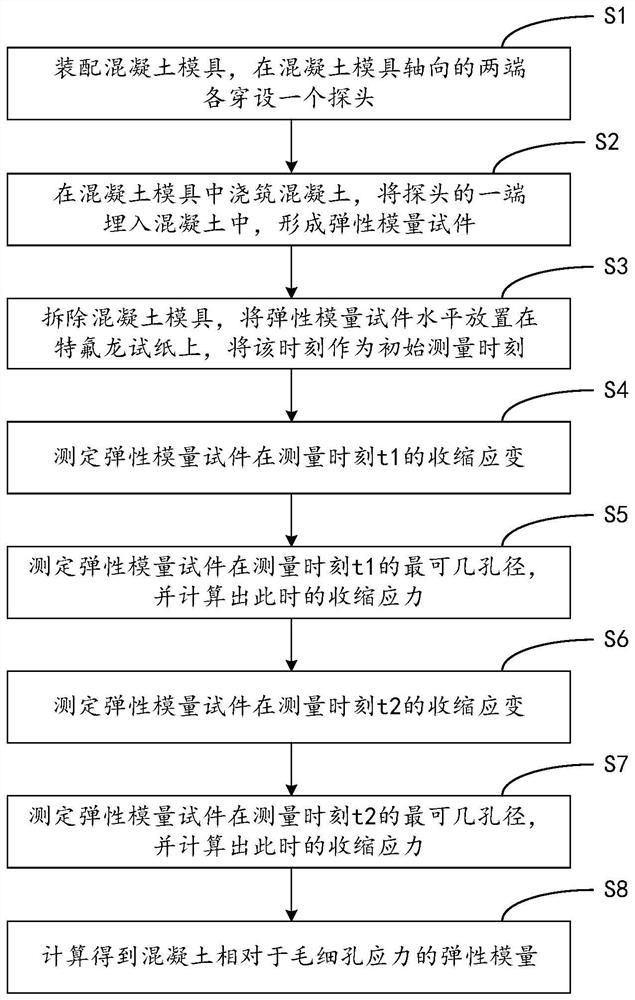

Concrete elasticity modulus measuring method based on capillary pore stress

ActiveCN112326419AThe result is accurateReduce mistakesStrength propertiesStructural engineeringShrinkage strain

The invention relates to the field of concrete mechanical property tests, and particularly discloses a concrete elasticity modulus measuring method based on capillary pore stress. The method comprisesthe following steps of: firstly, assembling a concrete mold, and then pouring concrete into the concrete mold to form an elasticity modulus test piece with probes at two ends; removing the concrete mold after the elasticity modulus test piece is initially set, and measuring the shrinkage strain and the shrinkage stress of the elasticity modulus test piece at a measurement moment t1 and a measurement moment t2; and calculating the elasticity modulus Et(delta t) of the elasticity modulus test piece relative to the capillary pore stress within delta t time, thereby obtaining the elasticity modulus of the concrete relative to the capillary pore stress. The elasticity modulus measuring method based on the capillary pore stress adopted by the invention does not need external loading, so that interference of external factors like the loading speed is avoided, the elasticity modulus of concrete relative to the capillary pore stress can be accurately measured, the constraint stress of the concrete is calculated, and the calculation method is smaller in error and more accurate in result.

Owner:CHONGQING UNIV

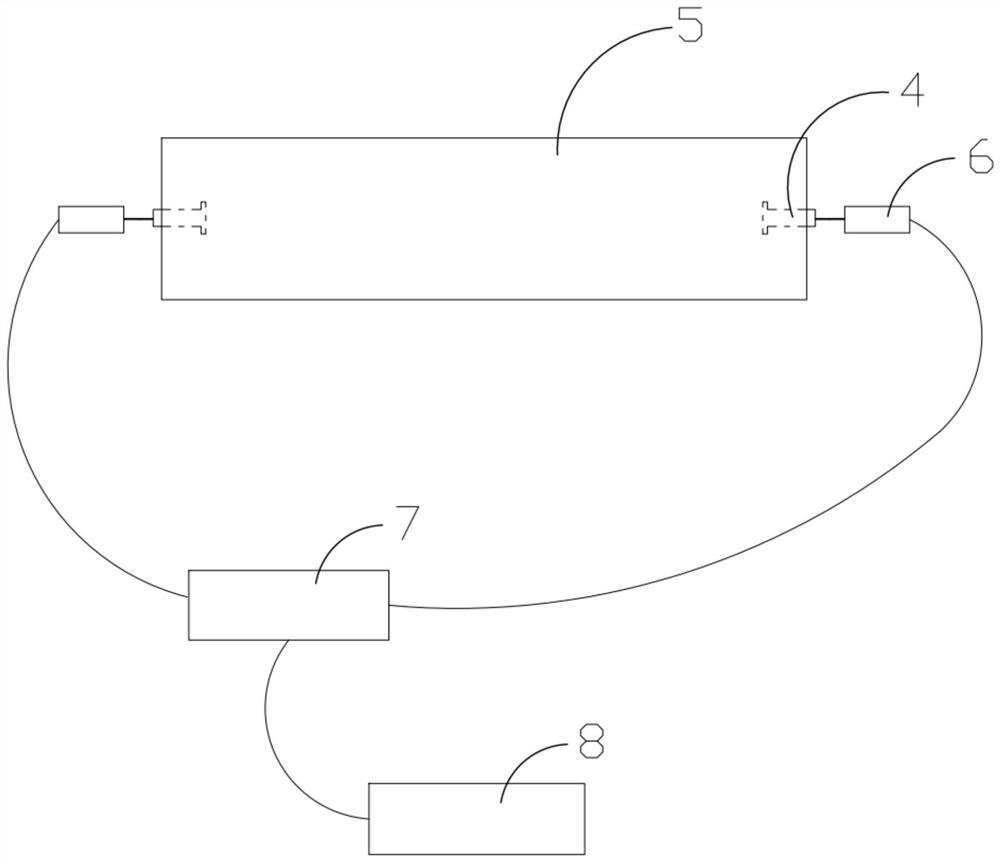

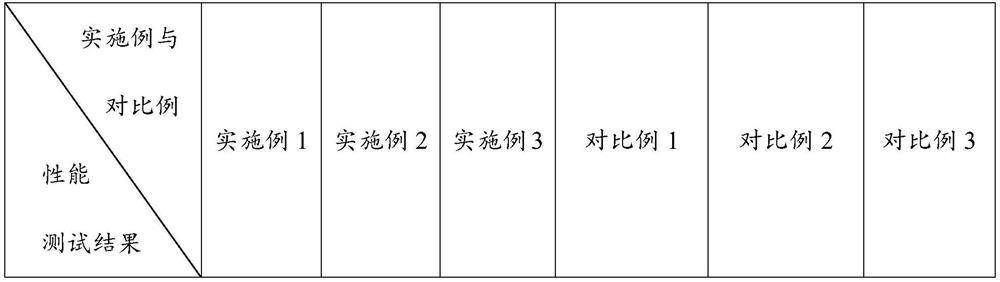

Magnesium oxychloride aeolian sand composite material capable of being subjected to 3D printing as well as preparation method and application thereof

ActiveCN112661479AReduced early contraction strainImprove crack resistanceAdditive manufacturing apparatusAggregate (composite)Magnesium chlorate

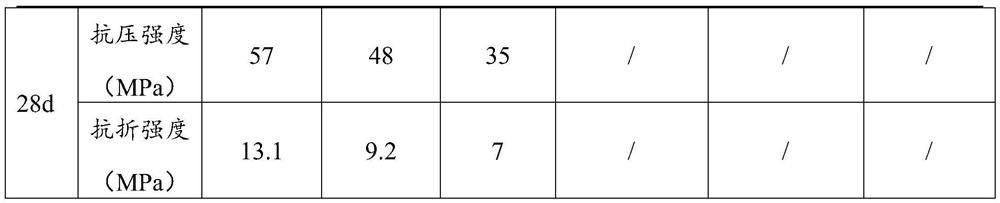

The invention provides a magnesium oxychloride aeolian sand composite material capable of being subjected to 3D printing, and relates to the technical field of building materials. The magnesium oxychloride aeolian sand composite material comprises the following components in parts by weight: 0.9-1.1 parts of magnesium oxide powder, 0.4-0.6 part of magnesium chloride hexahydrate, 2.0-4.0 parts of aeolian sand, 0.4-0.6 part of water, 0.1-0.2 part of fly ash, 0.1-0.2 part of silica fume and 0.003-0.008 part of cellulose ether; the magnesium oxide powder comprises MgO with the mass content of 70% or above and the balance being MgCO3 and CaO. The magnesium oxychloride aeolian sand composite material is extremely low in static yield stress, dynamic yield stress and plastic viscosity, extrudate is continuous and free of breakage, and the magnesium oxychloride aeolian sand composite material is more suitable for 3D printing; and the early shrinkage strain is -0.0028, the 28d compressive strength is 35-57 MPa and the breaking strength is 7-13.1 MPa within 8 hours under a high aggregate ratio.

Owner:HEBEI UNIV OF TECH

High-corrosion-resistance light resin concrete without restrained shrinkage and preparation method thereof

ActiveCN110776337ASmall shrinkageReduce early cure shrinkageSolid waste managementCeramicwareFiberEnergy absorption

The invention provides high-corrosion-resistance light resin concrete without restrained shrinkage and a preparation method thereof. The high-corrosion-resistance light resin concrete comprises the following components in parts by weight: 10.0%-18.0% of a resin system (composed of resin, a curing agent and an accelerant, wherein a proper amount of a diluent is added according to the viscosity of the resin), 40.0%-48.0% of light porous coarse aggregate, 15.0%-32.0% of sand, 4.0%-9.0% of fly ash, 2.0%-15.0% of waste rubber particles, 0.2%-2.0% of waste rubber powder and 0.1%-8.0% of chopped fibers. According to the invention, the waste rubber particles, the waste rubber powder and the lightweight aggregate are doped, so early free shrinkage of the resin concrete and shrinkage of the resin concrete under constraint conditions can be reduced; the curing time of the resin in the resin concrete is prolonged; stress relaxation of the resin concrete is increased; shrinkage strain of the concrete under constraint conditions is greatly reduced; early non-load cracks of the resin concrete are eradicated; and the problem of volume instability caused by large early curing shrinkage of the resinconcrete is solved, and meanwhile, vibration resistance and energy absorption characteristics of the resin concrete are also improved.

Owner:HARBIN ENG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com