Tubeless diagonal tyre

A bias-ply tire and inner tube technology, which is applied to tire parts, tire edges, transportation and packaging, etc., can solve the problems of shrinkage and deformation of the slit wrapping cloth, achieve shrinkage deformation and knotting, and improve air tightness and appearance Quality, effect of improving quality and airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

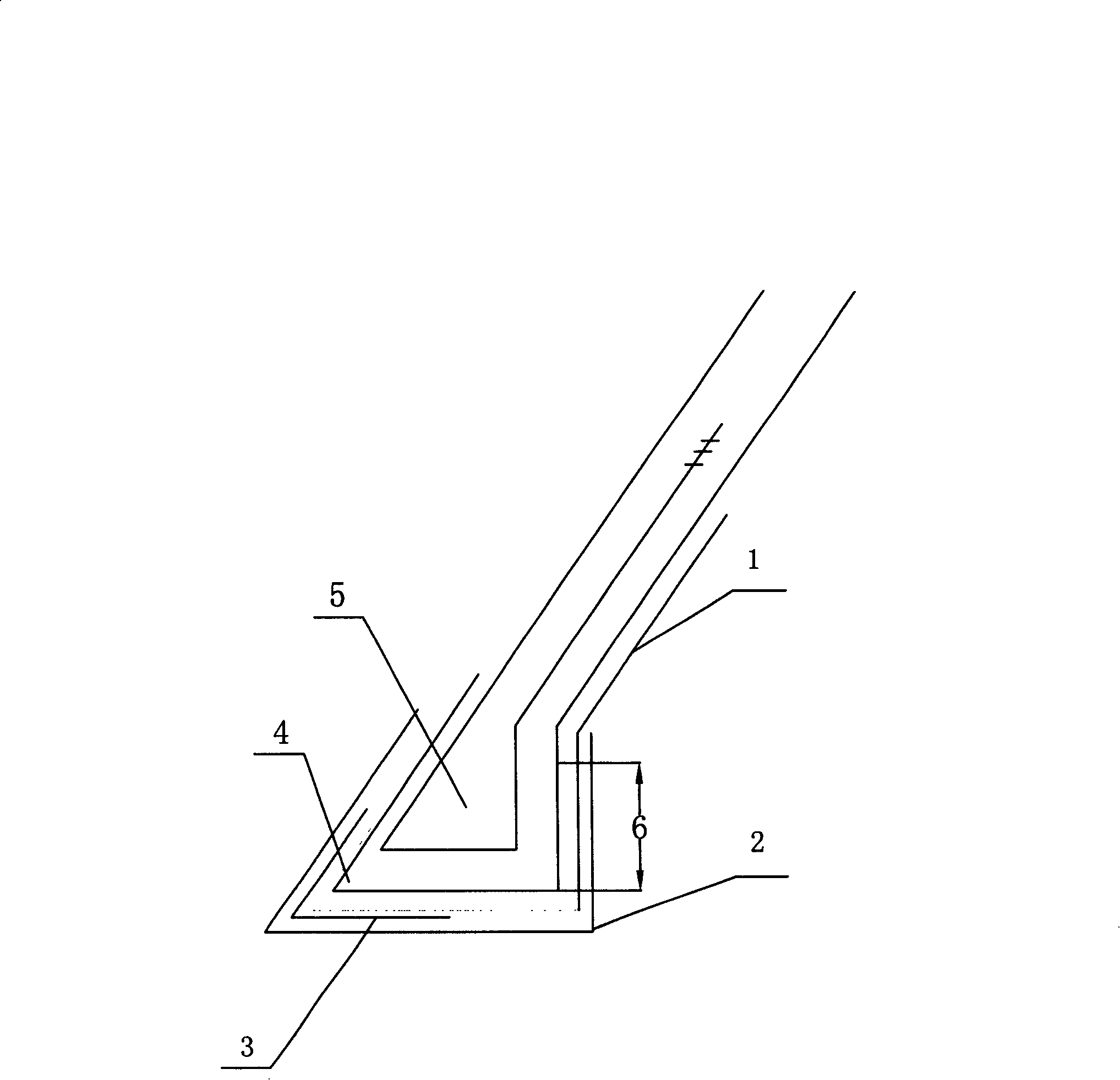

[0019] figure 1 It is a schematic diagram of the cross-sectional structure of the bead part of the tubeless bias tire in this example. There is a bead wire 5 inside the bead part of the carcass. There are 4 places of the fetal toe and outside the mouth wrapping cloth 1, there is a fetal toe wrapping cloth 3, and outside the mouth opening cloth 1 and the fetal toe wrapping cloth 3, there is a cover for completely covering the mouth opening cloth 1 and the fetal toe wrapping cloth 3 Sealing strip 2. The outer end of the fetal toe wrap 3 is aligned with the center of the bead steel wire 5 in the carcass, and is closely attached to the outer surface of the slit wrap 1 and the fetal toe 4, and the other end bends and extends to the inner side of the carcass. The slit wrap 1 in this example is nylon monofilament cloth, the toe wrap 3 is canvas, and the width of the toe wrap 3 is 30 mm.

Embodiment 2

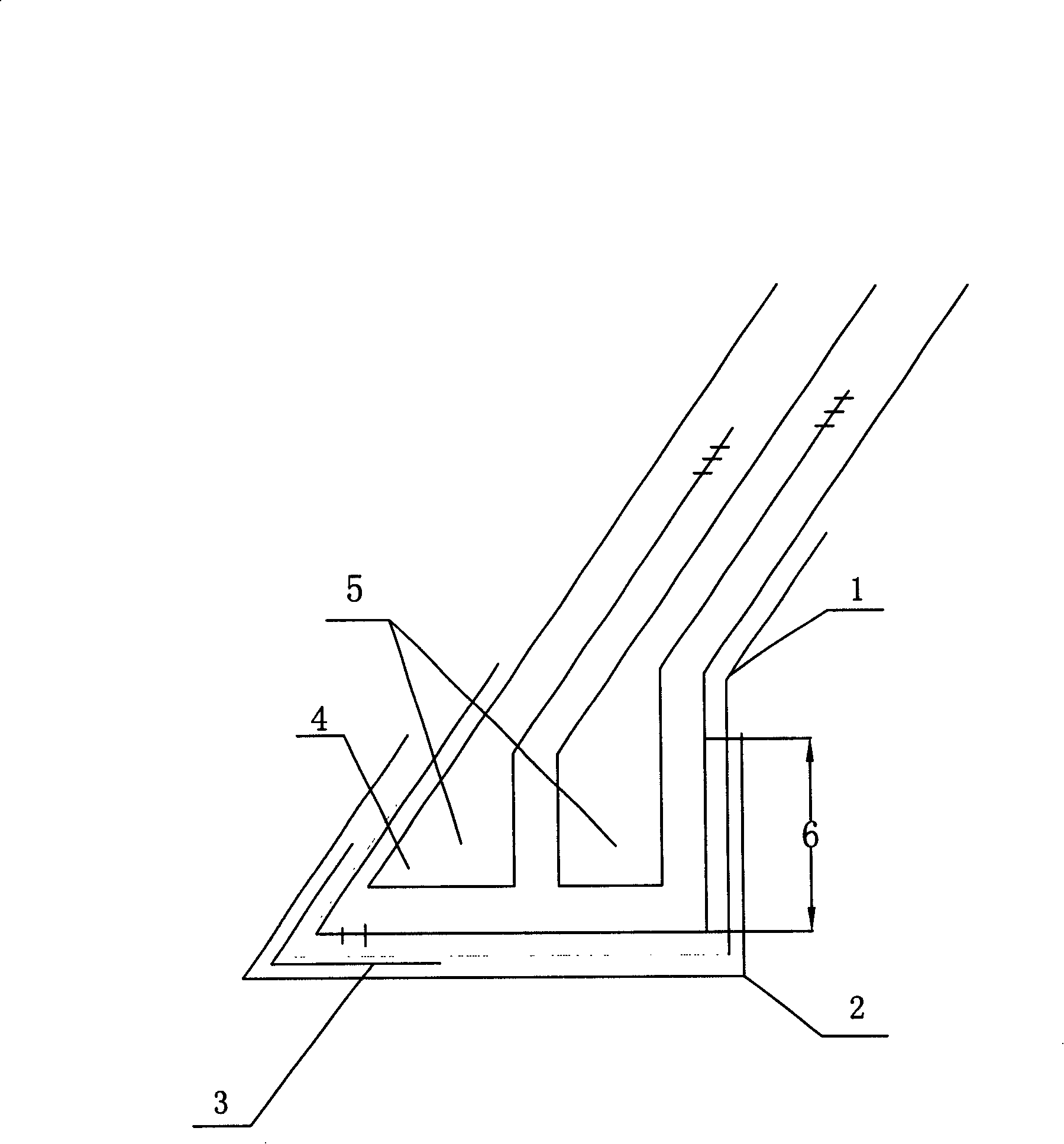

[0021] figure 2 It is a schematic diagram of the cross-sectional structure of the bead part of the tubeless bias tire in this example. There are two bead wires 5 in the bead part of the carcass. There are 4 fetal toe coverings and 1 outside the mouth wrapping cloth 3, and there is a fetal toe covering cloth 3 outside the slit opening 1 and the fetal toe covering cloth 3. Sealing strip 2. The outer end of the fetal toe cloth 3 is aligned with the center of the innermost bead wire 5 in the carcass, and is closely attached to the outer surface of the sub-mouth cloth 1 and the fetal toe 4, and the other end is curved and extended to the inside of the carcass . The slit wrap 1 in this example is nylon monofilament cloth, the toe wrap 3 is canvas, and the width of the toe wrap 3 is 40mm.

Embodiment 3

[0023] figure 2 It is a schematic diagram of the cross-sectional structure of the bead part of the tubeless bias tire in this example. There are two bead wires 5 in the bead part of the carcass. There are 4 fetal toe coverings and 1 outside the mouth wrapping cloth 3, and there is a fetal toe covering cloth 3 outside the slit opening 1 and the fetal toe covering cloth 3. Sealing strip 2. The outer end of the fetal toe cloth 3 is aligned with the center of the innermost bead wire 5 in the carcass, and is closely attached to the outer surface of the sub-mouth cloth 1 and the fetal toe 4, and the other end is curved and extended to the inside of the carcass . The slit wrap 1 in this example is spandex monofilament cloth, the toe wrap 3 is canvas, and the width of the toe wrap 3 is 40mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com