Green cement-based composite material with low shrinkage and high ductility

A technology of green cement and composite materials, applied in the field of construction engineering materials, can solve the problems of high cost, poor brittleness and ductility, low shrinkage and ductility, etc., and achieve the effect of solving high cost, low shrinkage and high ductility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

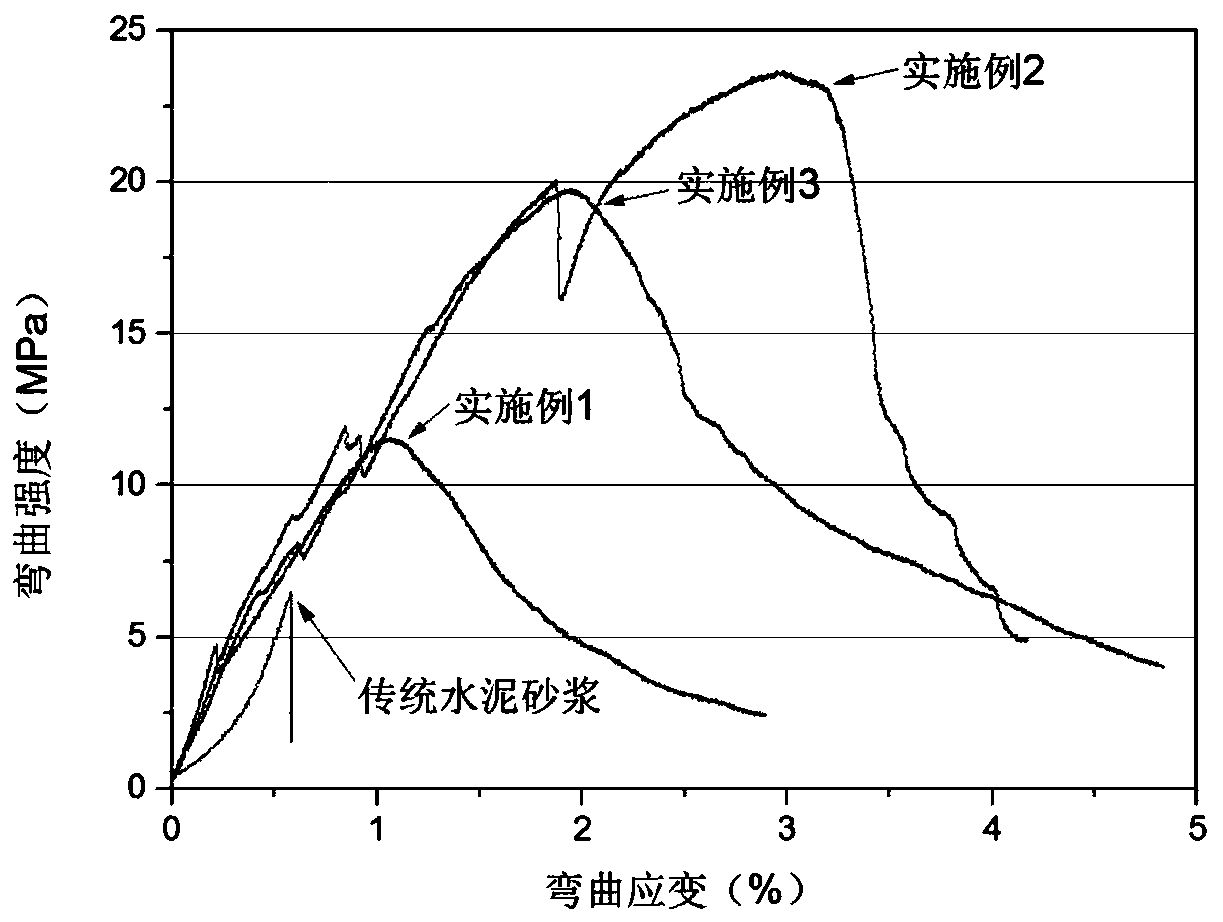

[0021] Example 1: 50 parts of cement, 30 parts of fly ash, 15 parts of granulated blast furnace slag, 15 parts of metakaolin, 0.2 part of polycarboxylate superplasticizer, 9 parts of calcium sulfoaluminate expansion agent, dispersible latex 0.3 parts of powder, 0.3 parts of defoamer, 50 parts of sand, 32 parts of water, wherein the hydrophilic polyvinyl alcohol fiber is 0.3% of the total mass. The shrinkage strain of the green cement-based composite material prepared in this example is 1003με, the compressive strength is 54MPa, and the flexural strength is 11.57MPa.

Embodiment 2

[0022] Example 2: 50 parts of cement, 30 parts of fly ash, 15 parts of granulated blast furnace slag, 15 parts of metakaolin, 0.2 part of polycarboxylate superplasticizer, 9 parts of calcium sulfoaluminate expansion agent, dispersible latex 0.3 parts of powder, 0.3 parts of defoamer, 45 parts of sand, 32 parts of water, wherein the hydrophilic polyvinyl alcohol fiber is 0.9% of the total mass. As shown in Tables 1, 2, and 3, the shrinkage strain of the green cement-based composite material prepared in this example is 935με, the compressive strength is 46.1MPa, and the flexural strength is 23.65MPa.

Embodiment 3

[0023] Example 3: 50 parts of cement, 30 parts of fly ash, 15 parts of granulated blast furnace slag, 15 parts of metakaolin, 0.2 part of polycarboxylate superplasticizer, 9 parts of calcium sulfoaluminate expansion agent, dispersible latex 0.3 parts of powder, 0.3 parts of defoamer, 40 parts of sand, 32 parts of water, wherein the hydrophilic polyvinyl alcohol fiber is 1.5% of the total mass. As shown in Tables 1, 2, and 3, the shrinkage strain of the green cement-based composite material prepared in this example is 869με, the compressive strength is 45.86MPa, and the flexural strength is 19.77MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com