Method for determining numerical control bending springback angle of homogeneous pipe

A bending springback, pipe technology, applied in electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as the error between the springback angle calculated value and the test value, and the change of the shrinkage strain ratio is not considered, so as to improve the prediction Accuracy, improving springback prediction accuracy, and the effect of improving springback prediction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

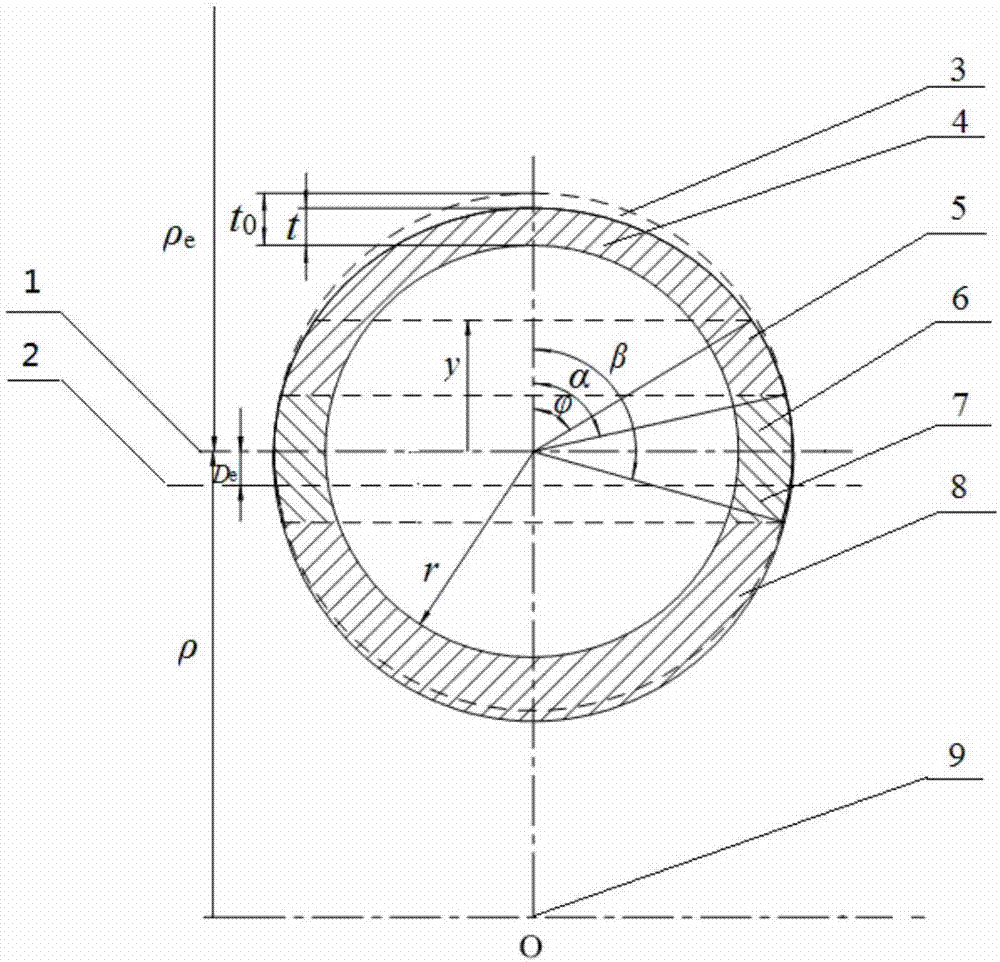

Embodiment 1

[0063] This embodiment is a method for calculating the springback angle of a homogeneous pipe in numerically controlled bending. In this embodiment, the curved pipe is made of TA18 titanium alloy, the outer diameter D is 12mm, and the initial wall thickness t 0 is 0.9mm, the bending radius ρ is 24mm, the bending angle θ before springback is 90゜, and the initial elastic modulus E 0 is 100380MPa, the stable value E of elastic modulus with plastic deformation a is 94109MPa, coefficient ξ, a 0 、a 1 , b 1 、a 2 and b 2 They are -59.08, 1.11687, 3.25907, 0.00409, 1.02701 and 0.02799 respectively, Poisson's ratio ν is 0.3, strengthening coefficient K is 1326.47MPa, hardening exponent n is 0.0702, and material constant b is -0.0006. The bending radius ρ is the distance from the bending center 9 to the geometrically neutral layer 1 .

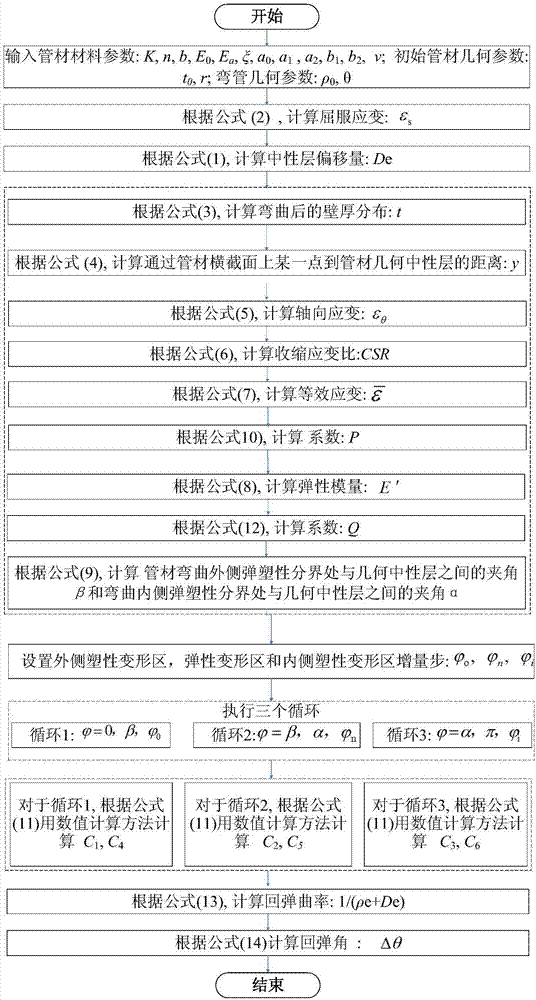

[0064] The calculation of the bending springback angle is realized through the following steps, and the specific process is:

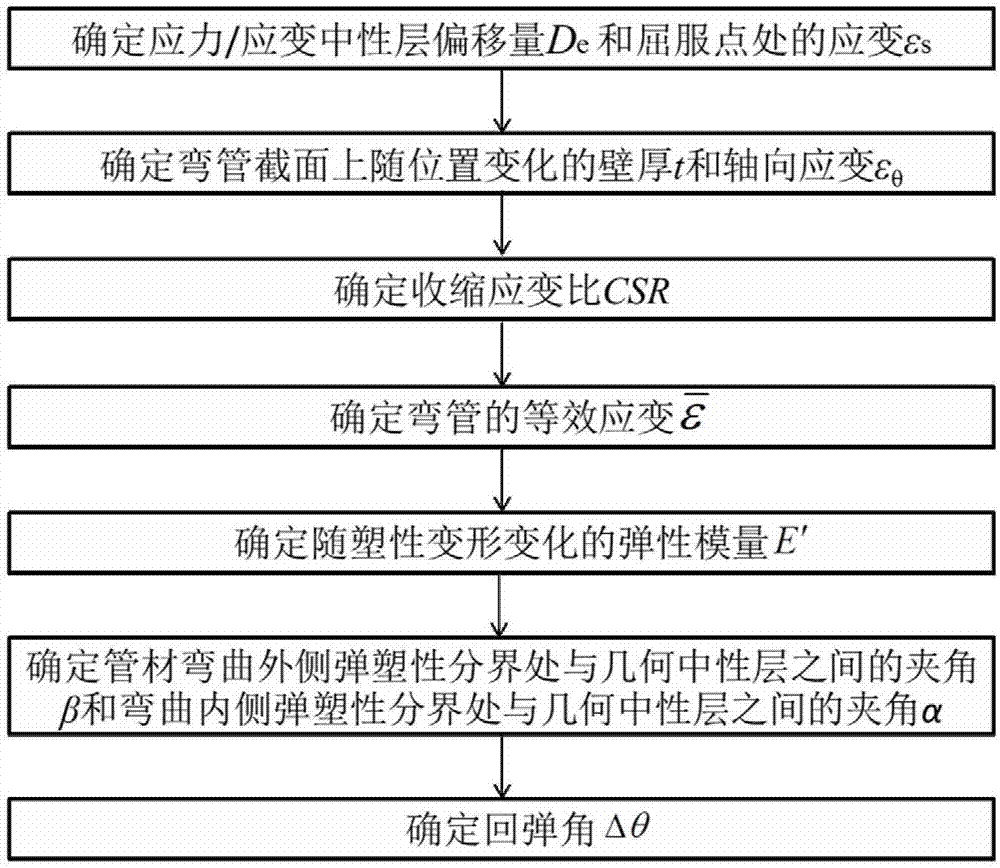

[0065] Step 1, det...

Embodiment 2

[0131] This embodiment is a method for calculating the springback angle of pipes in numerically controlled bending. In this embodiment, the curved pipe is made of TA18 titanium alloy, the outer diameter D is 12mm, and the initial wall thickness t 0 is 0.9mm, the bending radius ρ is 24mm, and the bending angle θ before springback is different from the bending angle of 120° in Example 1, and the initial elastic modulus E 0 is 100380MPa, the stable value E of elastic modulus with plastic deformation a is 94109MPa, coefficient ξ, a 0 、a 1 , b 1 、a 2 and b 2 They are -59.08, 1.11687, 3.25907, 0.00409, 1.02701 and 0.02799 respectively, Poisson's ratio ν is 0.3, strengthening coefficient K is 1326.47MPa, hardening exponent n is 0.0702, and material constant b is -0.0006.

[0132] The calculation of the bending springback angle is realized through the following steps, and the specific process is:

[0133] Step 1, determine the stress / strain neutral layer offset D e and the str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com