Bending Springback Prediction Method of Pipe Considering Elastic Modulus and Section Ellipse Distortion

A prediction method and technology of bending springback, applied in the direction of instrumentation, geometric CAD, calculation, etc., can solve problems such as springback angle prediction error, change of elastic modulus without considering bending cross-section distortion, springback angle error, etc., to achieve The effect of reducing the springback angle prediction error and improving the springback prediction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described below in conjunction with drawings and embodiments.

[0053] Embodiments of the present invention and its implementation process are as follows:

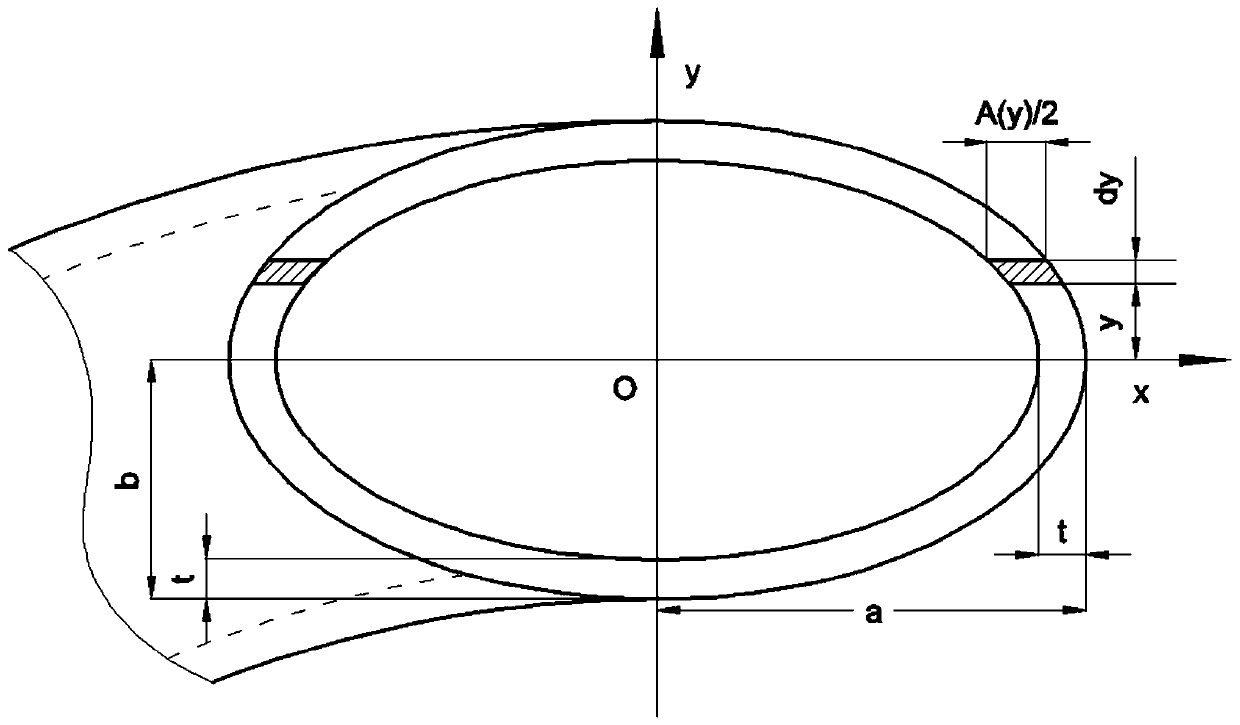

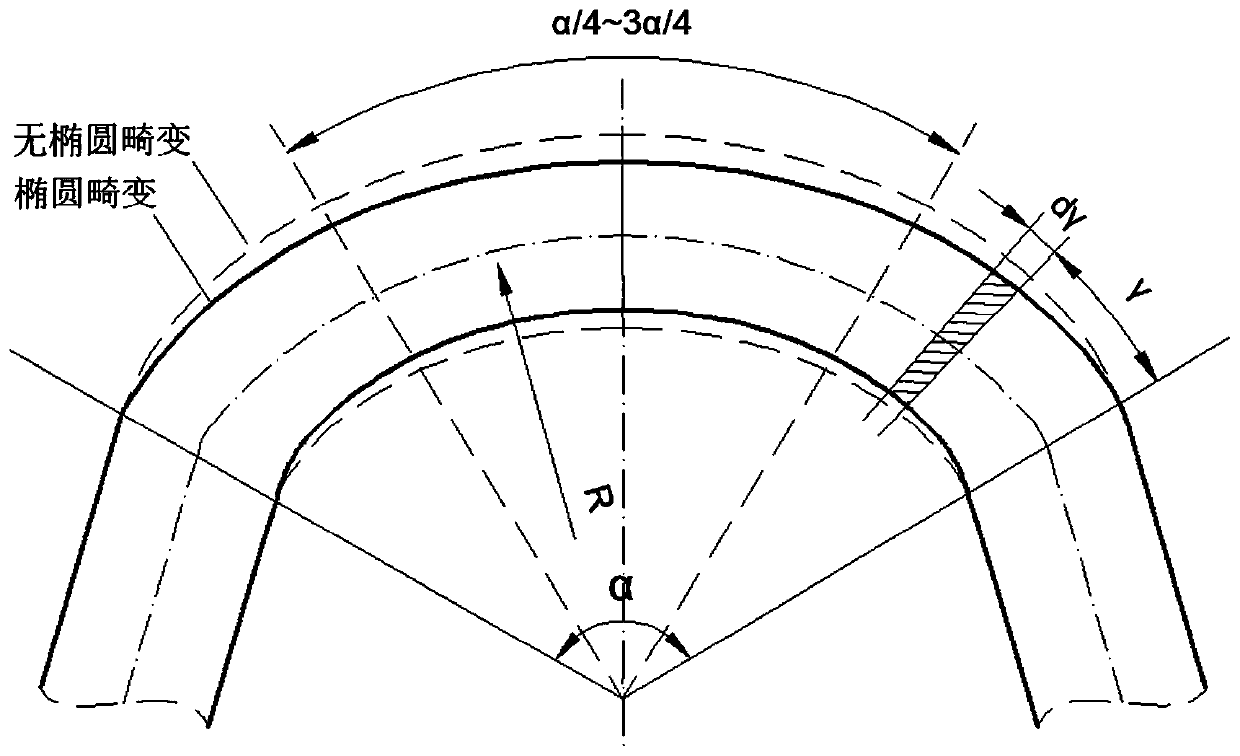

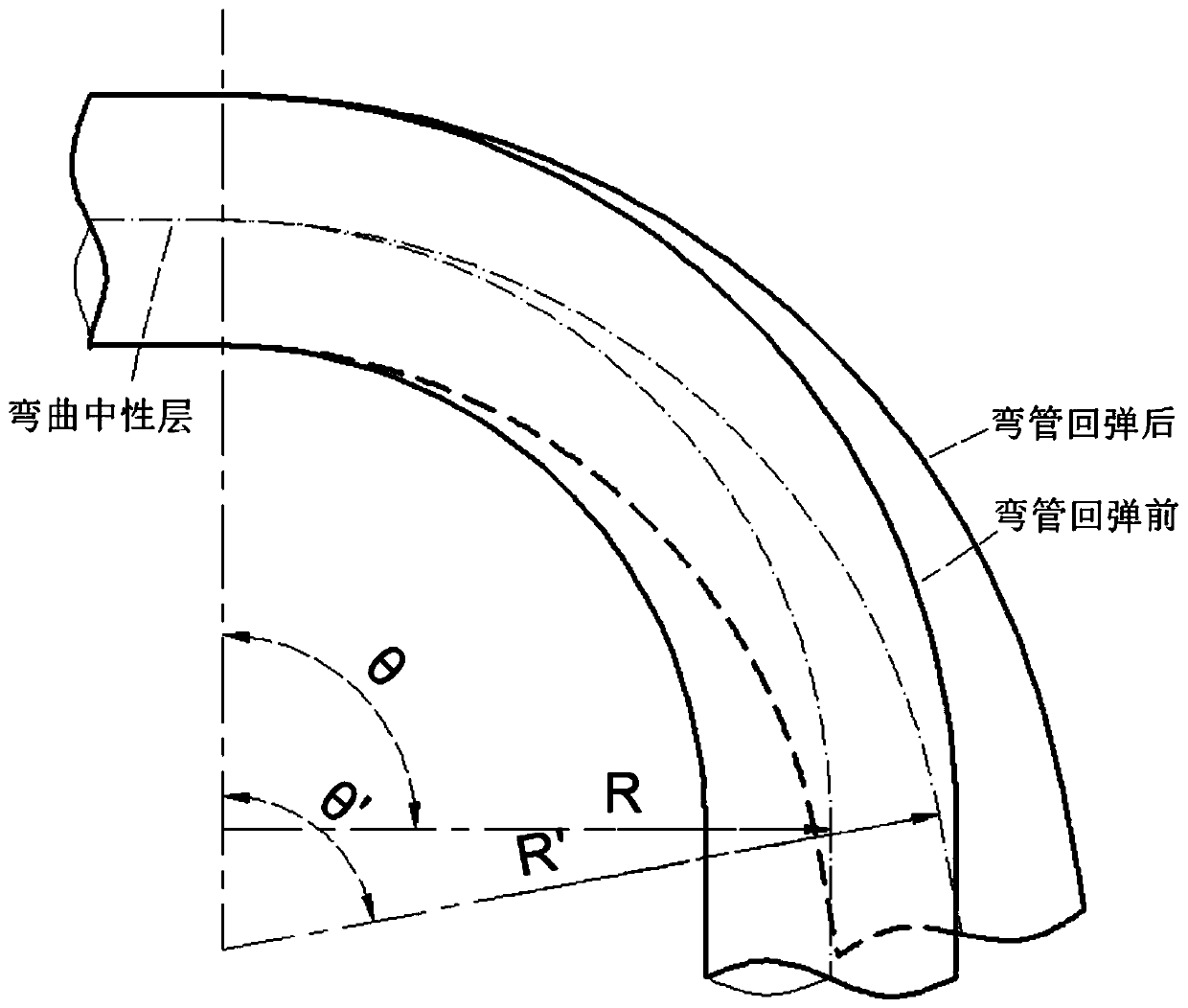

[0054] In this example, the curved pipe is made of 5A03 aluminum alloy, the wall thickness t is 7mm, the outer diameter D is 100mm, the bending radius is 200mm, the plastic coefficient C of the pipe is 273Mpa, the hardening index n is 0.160, and the initial elastic modulus E 0 is 73GPa, the extreme value E of elastic modulus with plastic deformation ext According to the experiment, 60GPa is taken, and the bending angle before springback is 120 degrees.

[0055] The prediction calculation of the bending springback angle is realized through the following steps, and the specific process is as follows:

[0056] 1) Determine the plastic coefficient C, hardening index n, and wall thickness t of the pipe by consulting the data and actual measurement;

[0057] In this example, by con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com