Road base material produced by stabilizing waste concrete construction waste aggregate with lime red mud

A technology for waste concrete and construction waste, applied in the field of road engineering, can solve the problems of destroying the natural landscape of mountains, soil erosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in more detail below in conjunction with specific implementation examples. It should be noted that the protection scope of the present invention is not limited thereto.

[0017] This embodiment includes the following steps:

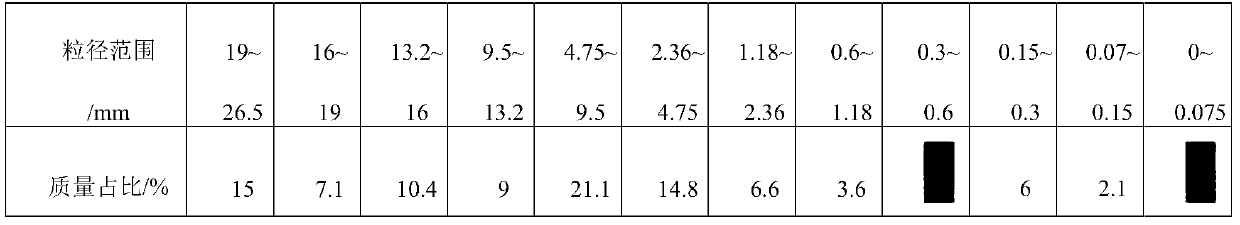

[0018] (1) Preparation of recycled coarse aggregate from waste concrete construction waste: the waste concrete construction waste undergoes coarse classification, sorting, impurity removal, crushing and screening to obtain refine coarse aggregate with a particle size range of 0-4.75 mm. And 4.75 ~ 31.5mm recycled coarse aggregate, mix the coarse and fine aggregate according to the mass ratio of 19:31, and let it dry naturally for later use. The particle size gradation of the mixed construction waste aggregate is shown in the table below, which meets the specification The scope specified in LF-B-1S in the recommended range table for lime and fly ash stable graded crushed stone in JTG TF20-2015 "Technical Rule...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com