Fireproofing and heat-insulating adhesive

A technology of fire prevention and heat preservation and adhesive, which is applied in the direction of heat preservation, fire protection and adhesive, etc. It can solve the problems of insufficient compressive strength, failure of the combustion performance of the core board, and insufficient adhesion between the core material and the color steel plate, etc. Achieve the effect of being conducive to the promotion and application of industrialization, light weight and fast coagulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 Embodiment 1~6 and comparative Embodiment 1~2

[0050] Step 1) Preparation of polystyrene foam substrate

[0051] Using polystyrene pre-expanded particles with a density of 5-15g / L as raw material, the steam penetration pressure P 1 MPa, steam penetration time is t 1 Prepare polystyrene foam sheets.

[0052] Step 2) Prepare polystyrene fireproof insulation board

[0053] The polystyrene foam board was placed in the fireproof coating modification equipment, and then the fireproof and thermal insulation adhesive formulated in Table 2 was added to the P 2 Added under high pressure of MPa into the fireproof coating modification equipment placed polystyrene foam board, and then in P 3 Standing time under MPa pressure t 2 , so that the fireproof and thermal insulation adhesive penetrates into the polystyrene foam board, so as to carry out coating modification, and then curing molding time t 3 , get EPS fire insulation board.

[0054] Step 3) prepare polystyrene color steel sandwich panel

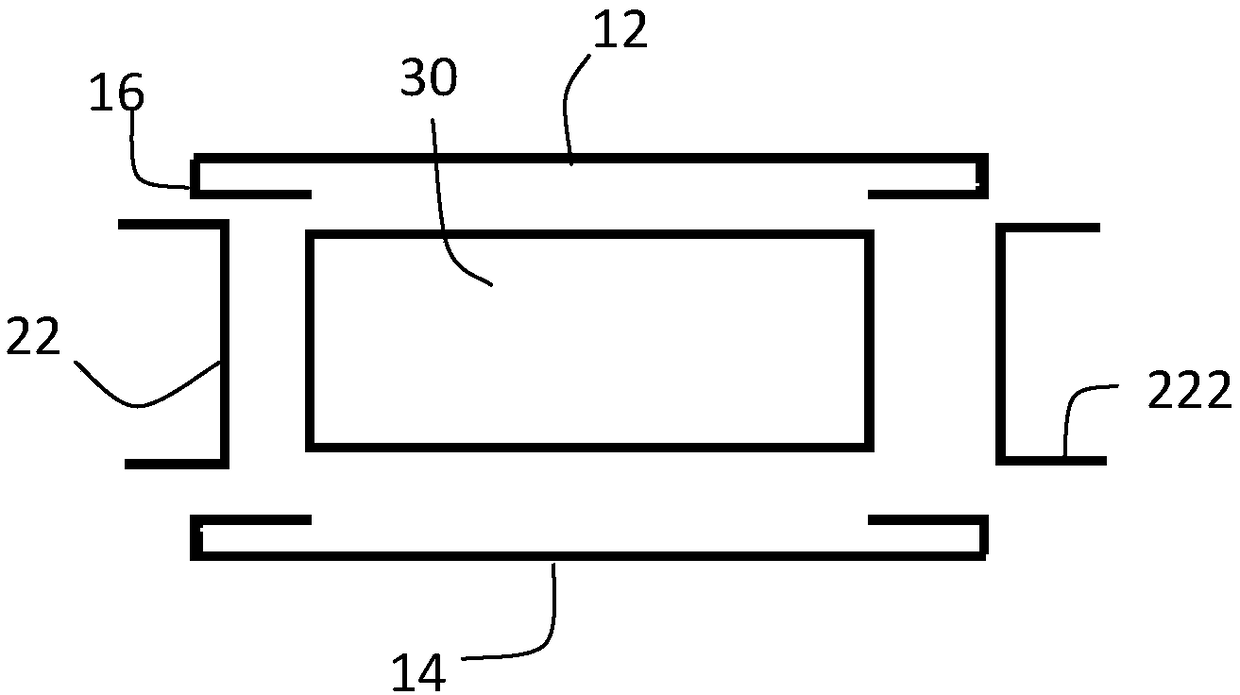

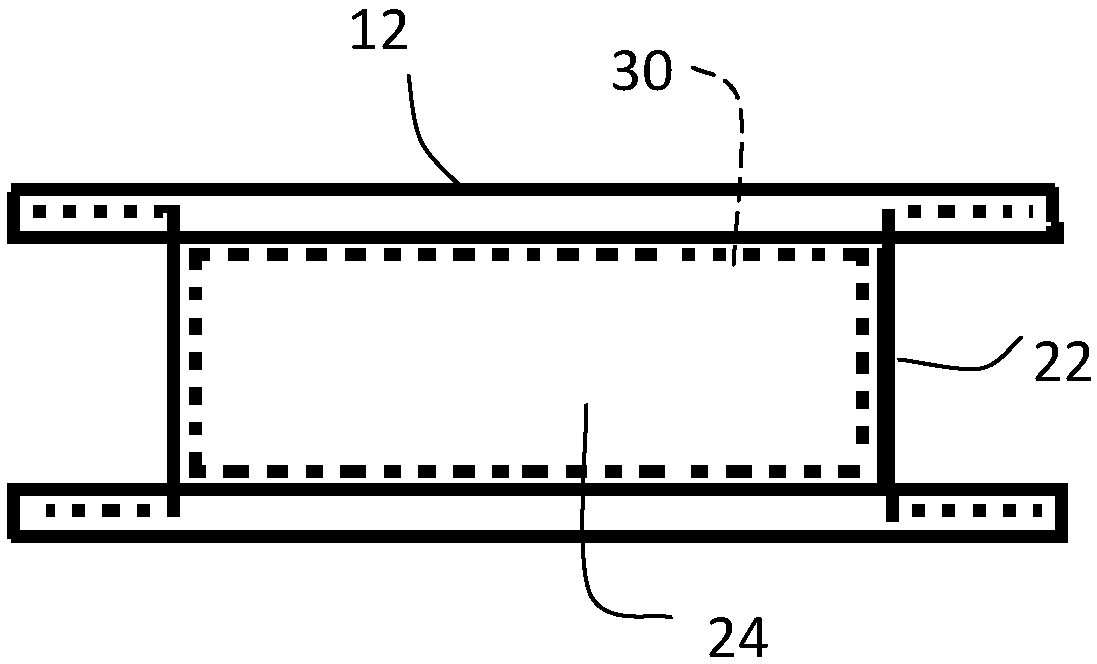

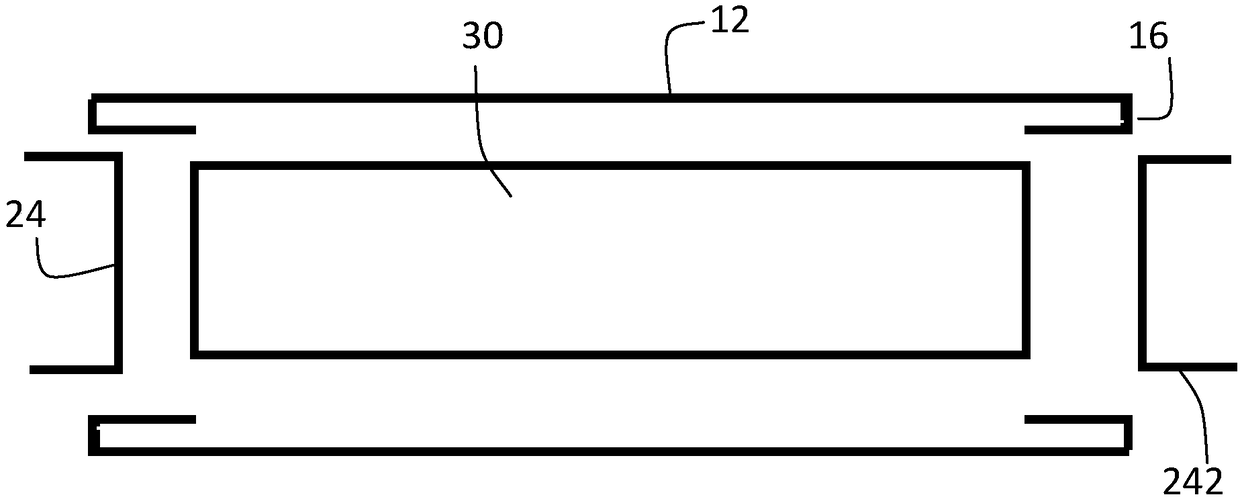

[0055] like Figure 1~4 As shown...

Embodiment 6

[0076] In Example 6, since no heat-insulating additive and infrared opacifying agent were added, the fire-proof adhesive had only a fire-proof effect and no heat-insulating function, and could not exert a synergistic effect of heat-insulating with the EPS foam board. The thermal conductivity of 1-5 fireproof and thermal insulation adhesives is relatively large under the same specific gravity.

[0077] In terms of the preparation of color steel sandwich panels, the present invention adopts the integrated combination of grooved side panels, grooved sealing panels, and upper and lower panels in structure. When the surface of the sandwich color steel plate is stressed, due to the and the integrated reinforcement of the edge of the core plate, and the groove structure of the side plate and the sealing plate acts as an external support frame, which further improves the bending strength of the sandwich color steel plate when the surface is stressed; on the other hand, due to the core ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Calorific value | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com