Composite engaging-type thermal-insulation wall plate composed of rigid polyurethane foam and reinforced foamed concrete

A technology of polyurethane rigid foam and reinforced foam, which is applied in the direction of building components, buildings, building structures, etc., can solve the problems of difficult to achieve technical indicators, long construction period, time-consuming, etc., and achieve improved earthquake resistance, enhanced pressure resistance, enhanced Effect of Water Penetration Resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

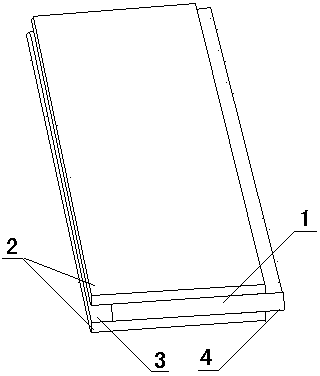

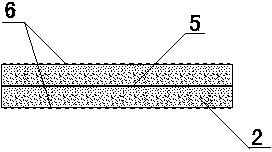

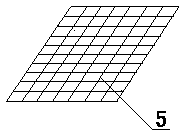

[0010] Referring to the accompanying drawings, a polyurethane rigid foam and reinforced foam concrete composite socket-type thermal insulation wall board includes a polyurethane rigid foam board 1 and a reinforced foam concrete board 2. The polyurethane rigid foam board 1 is used in the middle of the thermal insulation wall board, and polyurethane Both sides of the hard foam board 1 are respectively provided with reinforced foam concrete boards 2, and the polyurethane rigid foam board 1 is completely integrated with the reinforced foam concrete boards 2 on both sides, and one side is provided with a socket 3, and the opposite side is provided with a tenon 4. Constitute a composite thermal insulation wall panel; the reinforced foam concrete panel is provided with a steel mesh 5 inside and a fiber mesh 6 on both surfaces. When the present invention is produced, one side of the reinforced foam concrete board 2 on both sides and both sides of the rigid polyurethane foam board 1 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com