Temperature optimization design method and system for reducing buckling deformation of PCB after lamination

A technology for optimizing design and warping, applied in CAD circuit design, design optimization/simulation, computer-aided design, etc., can solve the problems of increased thickness and weight, lack of versatility, and affecting PCB production efficiency, etc., to reduce warping deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

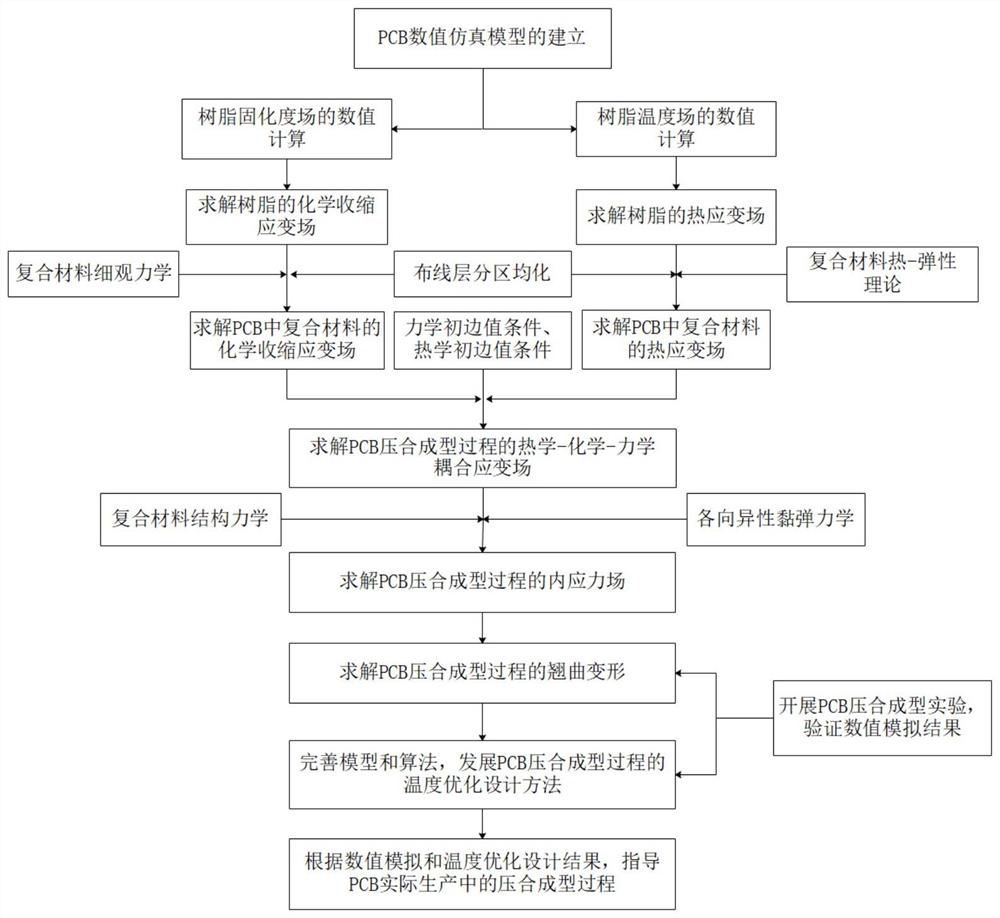

Embodiment 1

[0043] In one or more embodiments, a temperature optimization design method for reducing warpage deformation after PCB lamination is disclosed, using layered, partitioned modeling and thermal-chemical-mechanical coupling methods to simulate the PCB lamination process, Reveal the solidification deformation and residual stress formation mechanism of PCB during thermal compression-cold compression-opening and cooling to room temperature, and establish a thermal conduction-curing model of composite materials including thermal curing reaction, thermoelastic effect and physical and mechanical properties evolution of fiber composite materials , systematically and comprehensively analyze the size and regularity of the warping deformation change of the PCB during the pressing process, and form a prediction method for the curing deformation and residual stress of the PCB during the pressing process, and then can target various PCB specific pressing molding processes process, quickly and ...

Embodiment 2

[0085] In one or more embodiments, a temperature-optimized design system for reducing warpage after PCB lamination is disclosed, including:

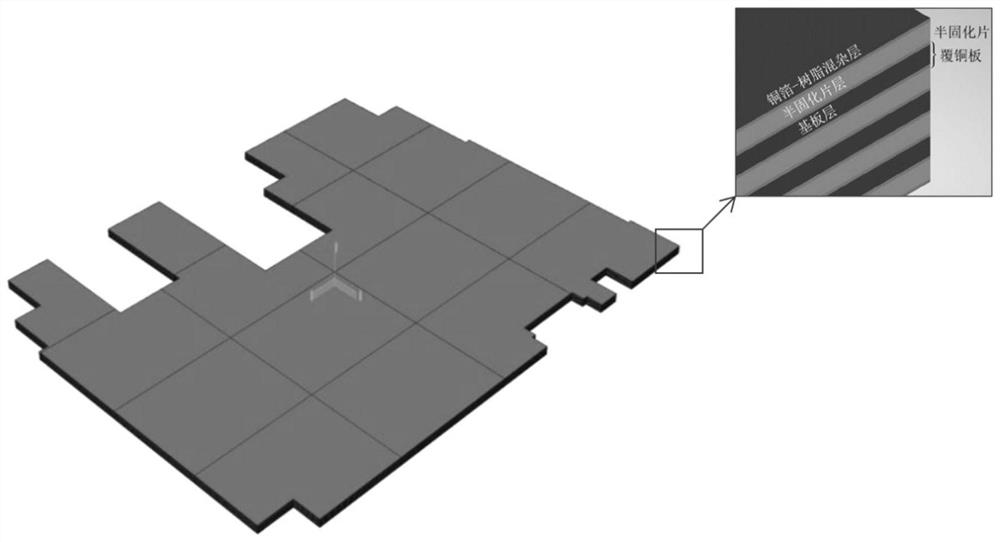

[0086] Model building blocks for layered modeling of PCBs, partitioning mixed layers, and defining equivalent material performance parameters in each region;

[0087] Numerical simulation module, the numerical simulation module includes three parts: heat transfer analysis unit, strain field calculation unit and stress field calculation unit;

[0088] The heat transfer analysis unit is used for heat transfer analysis of the PCB pressing process, calculating the temperature field and curing degree field of the resin in the PCB; determining the maximum curing temperature of the PCB hot pressing stage;

[0089] The strain field calculation unit is used to calculate the thermal strain field and chemical shrinkage strain field of the resin in the PCB based on the temperature field and the curing degree field; and then obtain the thermal strain...

Embodiment 3

[0094] In one or more embodiments, a terminal device is disclosed, including a server, the server includes a memory, a processor, and a computer program stored on the memory and operable on the processor, and the processor executes the The program realizes the temperature optimization design method of reducing the warping deformation of the PCB after lamination in the first embodiment. For the sake of brevity, details are not repeated here.

[0095] It should be understood that in this embodiment, the processor can be a central processing unit CPU, and the processor can also be other general-purpose processors, digital signal processors DSP, application specific integrated circuits ASIC, off-the-shelf programmable gate array FPGA or other programmable logic devices , discrete gate or transistor logic devices, discrete hardware components, etc. A general-purpose processor may be a microprocessor, or the processor may be any conventional processor, or the like.

[0096] The me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com