Method for determining dry shrinkage coefficient of cement stabilized macadam

A technology of cement-stabilized crushed stone and dry shrinkage coefficient, applied in the field of traffic civil engineering, can solve the problems of beams that are difficult to maintain a complete square cross-section, beam-type specimens are easily damaged when demoulded, and beam-type specimens are formed and segregated. To achieve the effect of easy operation, accurate weighing and accurate calculation of water loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

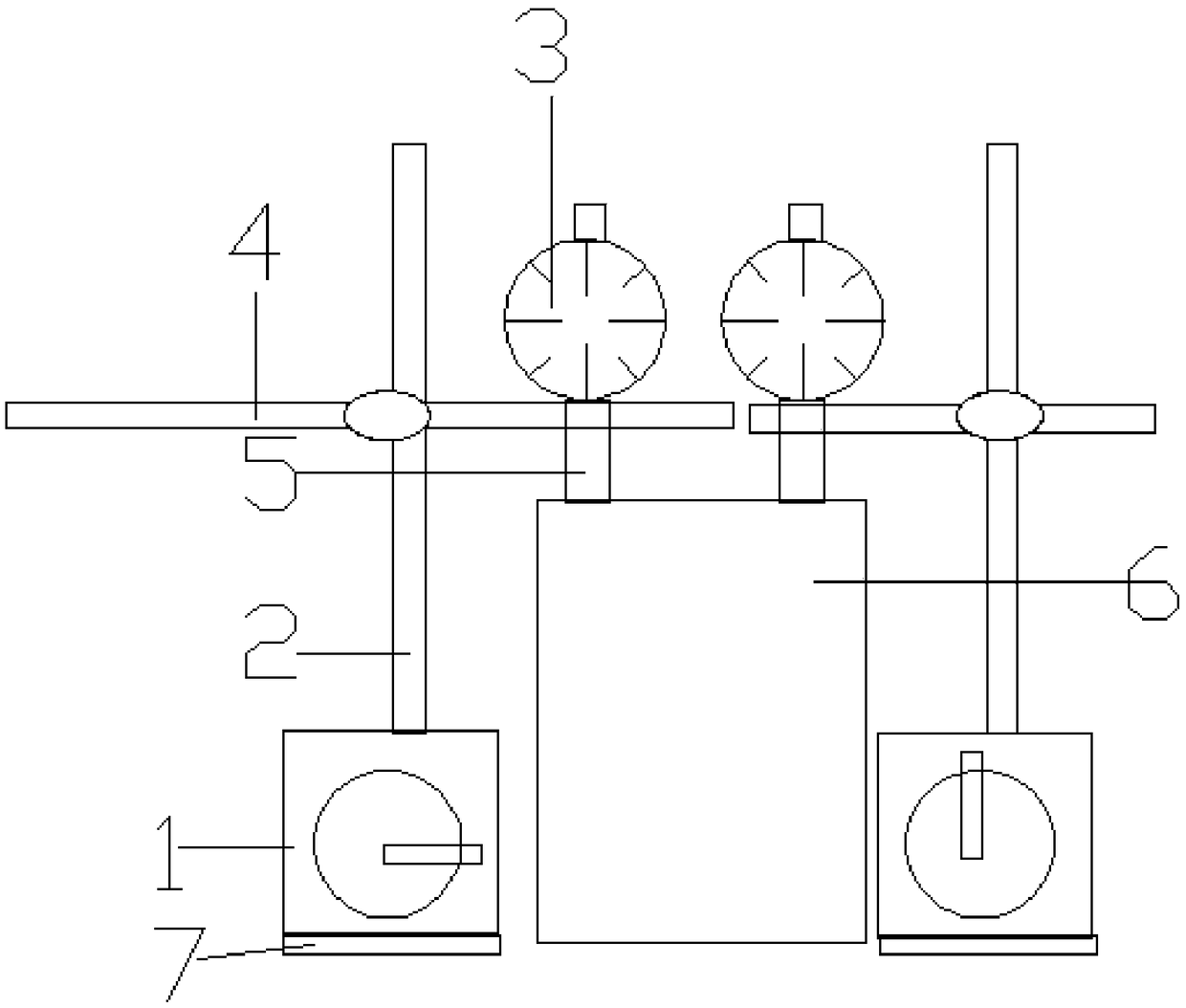

Method used

Image

Examples

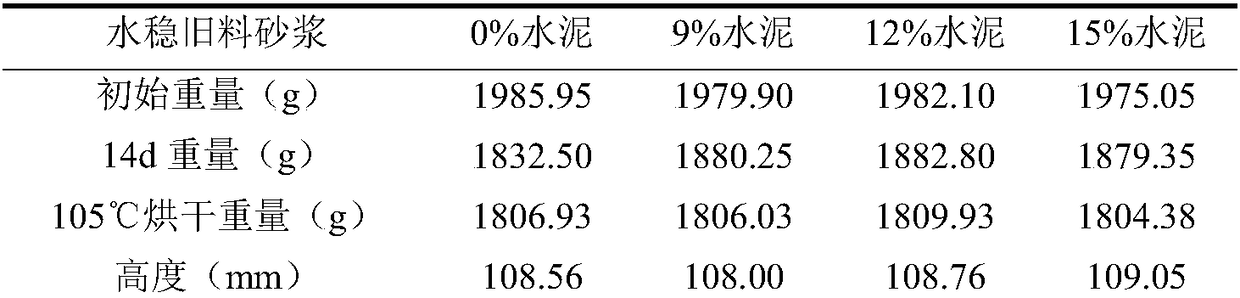

Embodiment 1

[0061] In this group of tests, old water-stabilized gravel fine aggregates were used, and the gradation of cement-stabilized gravel was determined by the recommended gradation in JTG / TF20-2015 of "Technical Rules for Construction of Highway Pavement Base" JTG / TF20-2015. Material Test Regulations "JTG E51-2009 Inorganic Binder Stabilized Materials Compaction Test Method Determine the optimum moisture content and maximum dry density of cement-stabilized gravel, and select the cement dosage.

[0062] According to the determined proportion of fine aggregate in the cement-stabilized crushed stone gradation, the dosage and water content of cement in the molded cement mortar specimens were calculated. Specifically, based on the proportion of fine aggregate in the gradation, the cement content and water content determined under all aggregates are divided by the proportion of fine aggregate to calculate the cement dosage and water content in the formed cement mortar specimen.

[0063] ...

Embodiment 2

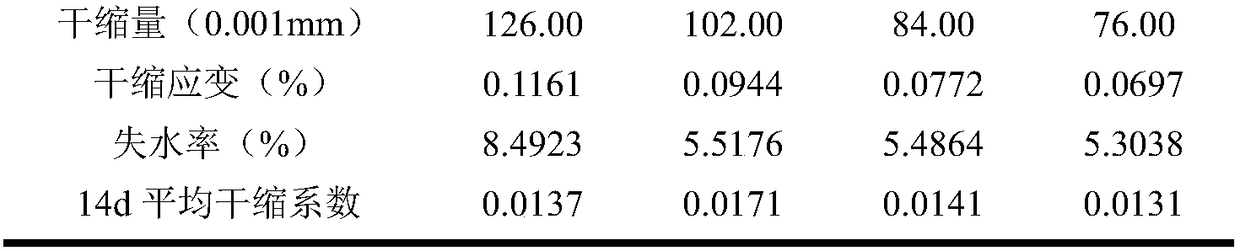

[0072] The difference from Example 1 is that this group of tests used fly ash crushed stone old material fine aggregate, under the overall blending mode, the content of fine aggregate below 4.75mm in the design gradation is about 40%, and the cement dosage of 3.5% Converted to cement mortar, it is 8.75%, and 5.5% cement dosage is converted to 13.75% in cement mortar; according to the maximum moisture content and maximum dry density of the molded specimen, the drying shrinkage test results measured after curing are shown in the following table 2-1 Show:

[0073] Table 2-1 Drying shrinkage test results of fly ash old material mortar

[0074]

[0075] From the results in Table 2-1, it can be concluded that the shrinkage coefficient of fly ash old material mortar first increases and then decreases and then increases with the increase of cement dosage. From the perspective of comprehensive shrinkage strain and shrinkage coefficient, the 0-4.75mm fine The optimum cement dosage f...

Embodiment 3

[0077] As a control group, new material fine aggregate was used in this group of experiments. Under the overall blending method, the content of fine aggregate below 4.75mm in the design gradation is about 40%, and the cement dosage of 3.5% is converted to 8.75% in cement mortar. , 5.5% cement dosage is converted to 13.75% in cement mortar; according to the maximum moisture content and maximum dry density of the molded specimen, the drying shrinkage test results measured after curing are shown in the following table 3-1:

[0078] Table 3-1 Drying shrinkage test results of new mortar

[0079]

[0080] From the results in Table 3-1, it can be concluded that the shrinkage coefficient of new fine aggregate decreases firstly and then increases and then decreases with the increase of cement dosage. From the perspective of comprehensive shrinkage strain and shrinkage coefficient, the fine aggregate of 0-4.75mm The cement-stabilized macadam with new limestone aggregate as the aggreg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com