Magnesium oxychloride aeolian sand composite material capable of being subjected to 3D printing as well as preparation method and application thereof

A 3D printing and composite material technology, applied in the field of magnesium oxychloride aeolian sand composite material and its preparation, can solve the problems of difficult molding, environmental pollution, large early shrinkage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The present invention also provides a preparation method of the 3D-printable magnesium oxychloride aeolian sand composite material described in the above technical solution, comprising the following steps:

[0038] (1) mixing magnesium oxide powder, aeolian sand, fly ash and silica fume to obtain a mixed powder;

[0039] (2) Magnesium chloride hexahydrate is dissolved in water, then mixed with the mixed powder obtained in the step (1), to obtain a prefabricated slurry;

[0040] (3) mixing the prefabricated slurry obtained in the step (2) with cellulose ether to obtain a 3D printable magnesium oxychloride aeolian sand composite material.

[0041] The invention mixes magnesium oxide powder, drift sand, fly ash and silica fume to obtain mixed powder.

[0042] In the present invention, the equipment for mixing the magnesium oxide powder, aeolian sand, fly ash and silica fume is preferably a concrete mixer. In the present invention, the mixing time of the magnesium oxide p...

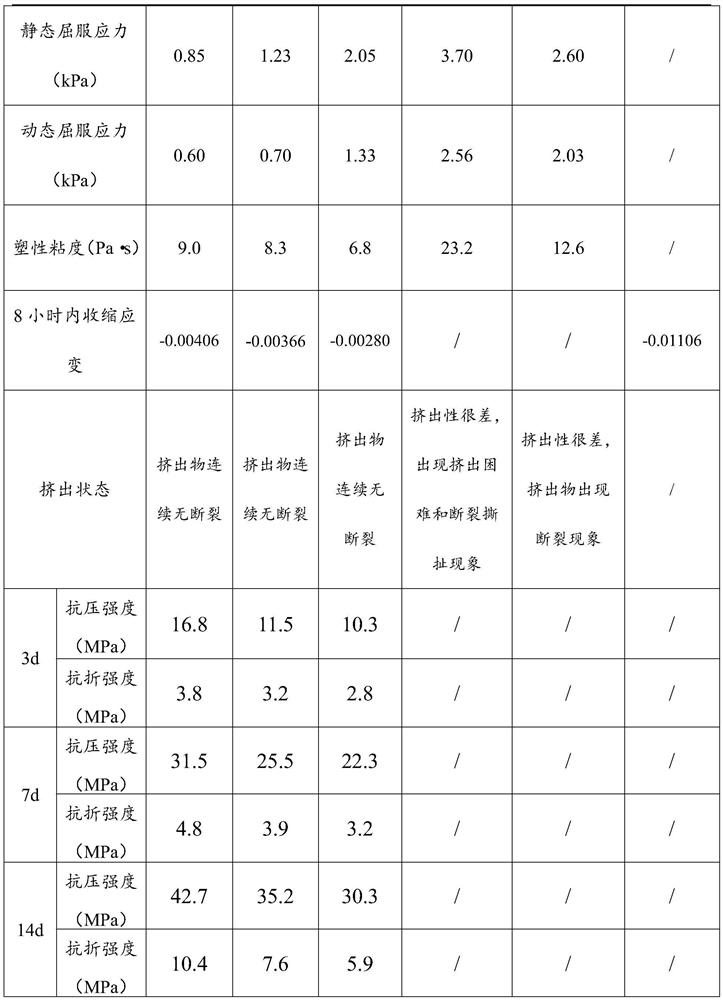

Embodiment 1

[0055] In Example 1, the magnesium oxychloride aeolian sand composite material that can be printed in 3D is calculated in parts by weight, and its components are as follows:

[0056] 0.9 parts of magnesium oxide powder of 80-120 μm (MgO mass percentage content is 71.2%, the balance is MgCO 3 and CaO), 0.4 parts of magnesium chloride hexahydrate (mass percentage of magnesium chloride is 45.5%), 0.4 parts of water, 0.1 part of Class I fly ash of 50-100 μm, 0.1 part of silica fume of 10-35 μm, and wind of 100-150 μm 2.0 parts of accumulated sand and 0.005 parts of hydroxypropyl methylcellulose with a water content of 2.1%, a pH value of 6.5 (1% solution, 25°C), and a viscosity of 95 Pa·s (2% aqueous solution, 20°C);

[0057] The preparation method of described 3D printable magnesium oxychloride aeolian sand composite material, concrete steps are as follows:

[0058] (1) Pour magnesium oxide powder, aeolian sand, fly ash and silica fume into a concrete mixer and mix for 2 minutes...

Embodiment 2

[0063] In Example 2, the magnesium oxychloride aeolian sand composite material that can be printed by 3D is calculated in parts by weight, and its components are as follows:

[0064] 1.0 parts of 80-120 μm magnesium oxide powder (MgO mass percentage content is 71.2%, the balance is MgCO 3 and CaO), 0.5 parts of magnesium chloride hexahydrate (mass percentage of magnesium chloride is 45.5%), 3.0 parts of 100-150 μm aeolian sand, 0.5 parts of water, 0.15 parts of 50-100 μm Class I fly ash, 10-35 μm 0.15 parts of silica fume and 0.005 parts of hydroxypropyl methylcellulose with a water content of 2.1%, a pH value of 6.5 (1% solution, 25°C), and a viscosity of 95 Pa·s (2% aqueous solution, 20°C);

[0065] The preparation method of described 3D printable magnesium oxychloride aeolian sand composite material, concrete steps are as follows:

[0066] (1) Pour magnesium oxide powder, aeolian sand, fly ash and silica fume into a concrete mixer and mix for 2 minutes to obtain a mixed po...

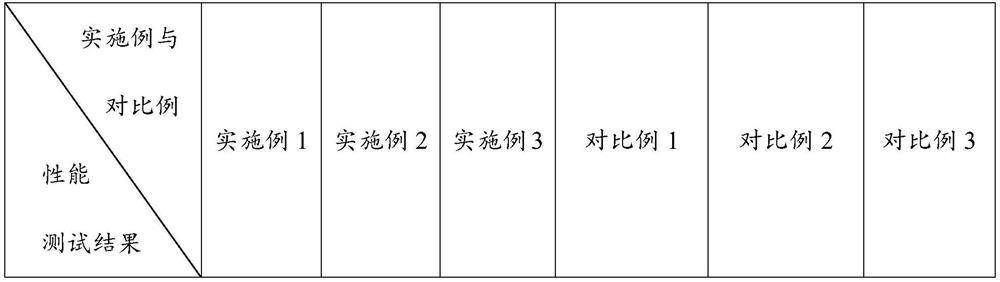

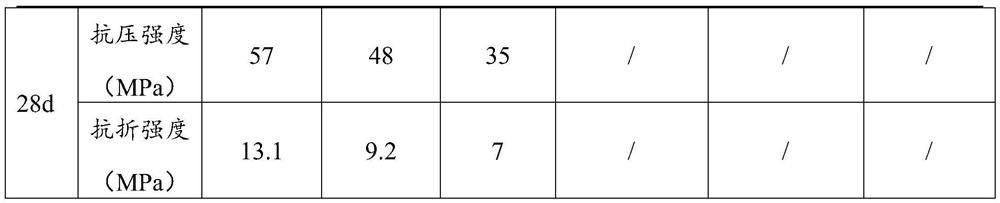

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com