High-ductility concrete and preparation method thereof

A high ductility concrete and concrete technology, applied in the field of concrete, can solve the problems of small increase in concrete ductility, delay in cement hydration and condensation, and strength not reaching the ideal value, etc., to achieve enhanced flexibility, enhanced adaptability, and reduced polarity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

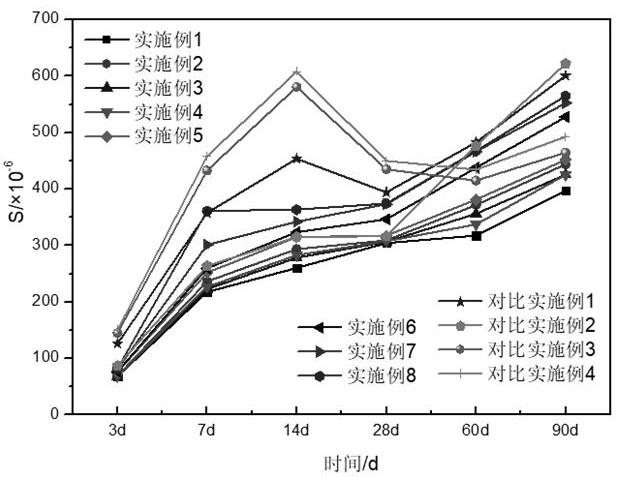

Examples

preparation example 1

[0043] Add 23 parts of POSS-glycidyl isobutyl ester to a mixed solvent composed of 80 parts of deionized water and 80 parts of tetrahydrofuran, stir until completely dissolved, add 100 parts of polyvinyl alcohol fiber and mix well, then add 30wt% sodium hydroxide Adjust the pH of the solution to 10, raise the temperature to 100°C and react for 3 hours, and finally add 15% dilute hydrochloric acid solution to adjust the pH to neutral, filter, wash, and dry to obtain grafted modified polyvinyl alcohol fibers.

preparation example 2

[0045] The rest are the same as Preparation Example 1, except that the consumption of POSS-glycidyl isobutyl ester is 18 parts.

preparation example 3

[0047] The rest are the same as in Preparation Example 1, except that the amount of POSS-glycidyl isobutyl ester is 10 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com