Preparation method for electrode with three-dimensional structure formed by coating nickel sulfide by fold graphene through self-repairing

A graphene and self-repairing technology, which is applied in the field of nanomaterials and electrochemistry, can solve the problems of excessive changes in electrode structure and low conductivity, and achieve the effect of fast charging and discharging with large currents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

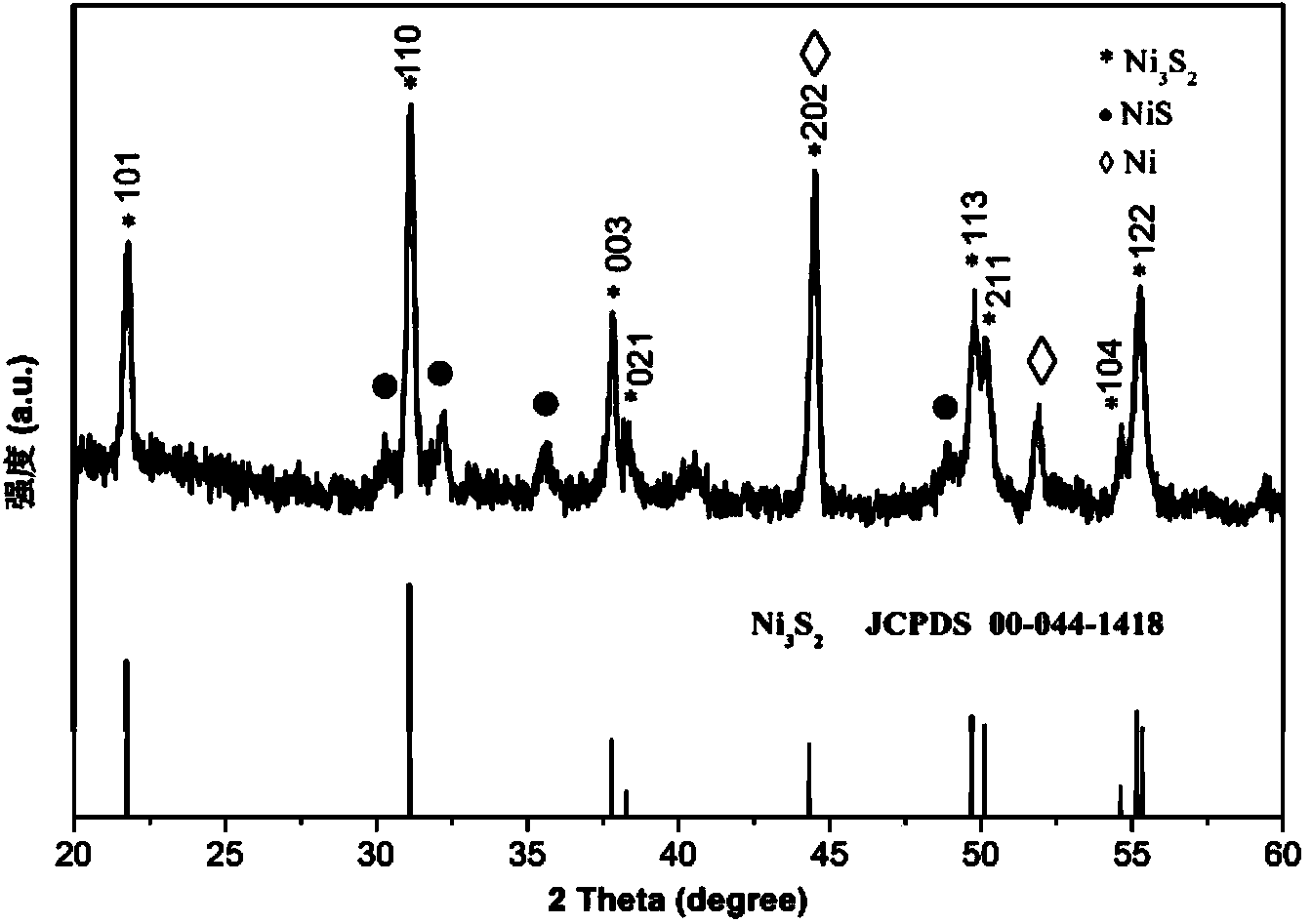

[0031] Embodiment 1: as Figure 6 shown

[0032] One, the preparation of graphene dispersion liquid:

[0033] a) Add 1g of graphite powder and 23ml of concentrated sulfuric acid in a 250ml Erlenmeyer flask, mix and stir at room temperature for 24 hours;

[0034] b) Put the Erlenmeyer flask into a constant temperature water bath, the reaction temperature is 40 degrees Celsius, and add 100mgNaNO to the dispersion obtained in step a) 3 , stirred for 5 minutes, then slowly added 1500mgKMnO 4 , and keep the solution temperature below 45 degrees Celsius, and stir for 30 minutes;

[0035] c) Add 3ml of deionized water to the dispersion obtained in step b), stir for 5 minutes, then add 3ml of deionized water, then stir for 5 minutes, then add 40ml of deionized water, and stir for 15 minutes;

[0036] d) Remove the Erlenmeyer flask from the water bath, add 140ml of deionized water and 10ml of 30% H 2 o 2 to stop the oxidation reaction;

[0037] e) The suspension obtained in step...

Embodiment 2

[0052] One, the preparation of graphene dispersion liquid: same as embodiment 1;

[0053] 2. Preparation of three-dimensional wrinkled graphene self-healing coated nickel sulfide structure electrode

[0054] 1) Prepare 50mL of NaOH solution with a mass fraction of 10%, add 0.25g S, 0.65g NaOH to it 2 S·9H 2 0, stirring in a water bath until an orange-yellow transparent solution is formed, and the temperature of the water bath is between 60 degrees Celsius;

[0055] 2) Add 10 mL of graphene oxide solution (concentration is about 4.7 mg / mL) to the solution obtained in step 1), and stir with magnetic force for 1 hour;

[0056] 3) Add about 72 mL of dilute hydrochloric acid with a mass fraction of 5% to the solution obtained in step 2), adjust the pH of the solution to 2, a white precipitate precipitates out, and stir magnetically for 1 hour;

[0057] 4) Suction filtration of the suspension obtained in step 3) to obtain graphene-coated sulfur particles, and drying in air at 70 ...

Embodiment 3

[0062] One, the preparation of graphene dispersion liquid: same as embodiment 1;

[0063] 2. Preparation of three-dimensional wrinkled graphene self-healing coated nickel sulfide structure electrode

[0064] 1) Prepare 50mL of NaOH solution with a mass fraction of 10%, add 0.25g S, 0.65g NaOH to it 2 S·9H 2 0, stirring in a water bath until an orange-yellow transparent solution is formed, and the temperature of the water bath is between 60 degrees Celsius;

[0065] 2) Add 5 mL of graphene oxide solution (concentration is about 4.7 mg / mL) to the solution obtained in step 1), and stir magnetically for 1 hour;

[0066] 3) Add about 72 mL of dilute hydrochloric acid with a mass fraction of 5% to the solution obtained in step 2), adjust the pH of the solution to 2, a white precipitate precipitates out, and stir magnetically for 1 hour;

[0067] 4) Suction filtration of the suspension obtained in step 3) to obtain graphene-coated sulfur particles, and drying in air at 70 degrees ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com