Silicon-based cathode composite material for lithium ion battery and preparation method thereof

A composite material and silicon material technology, which is applied in the field of porous silicon-based negative electrode composite materials for lithium ion batteries, can solve the problems of high production cost of silicon-based negative electrode materials, polluting industrialized production, complicated processes, etc., and achieves low production cost and increased electrical conductivity. , the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

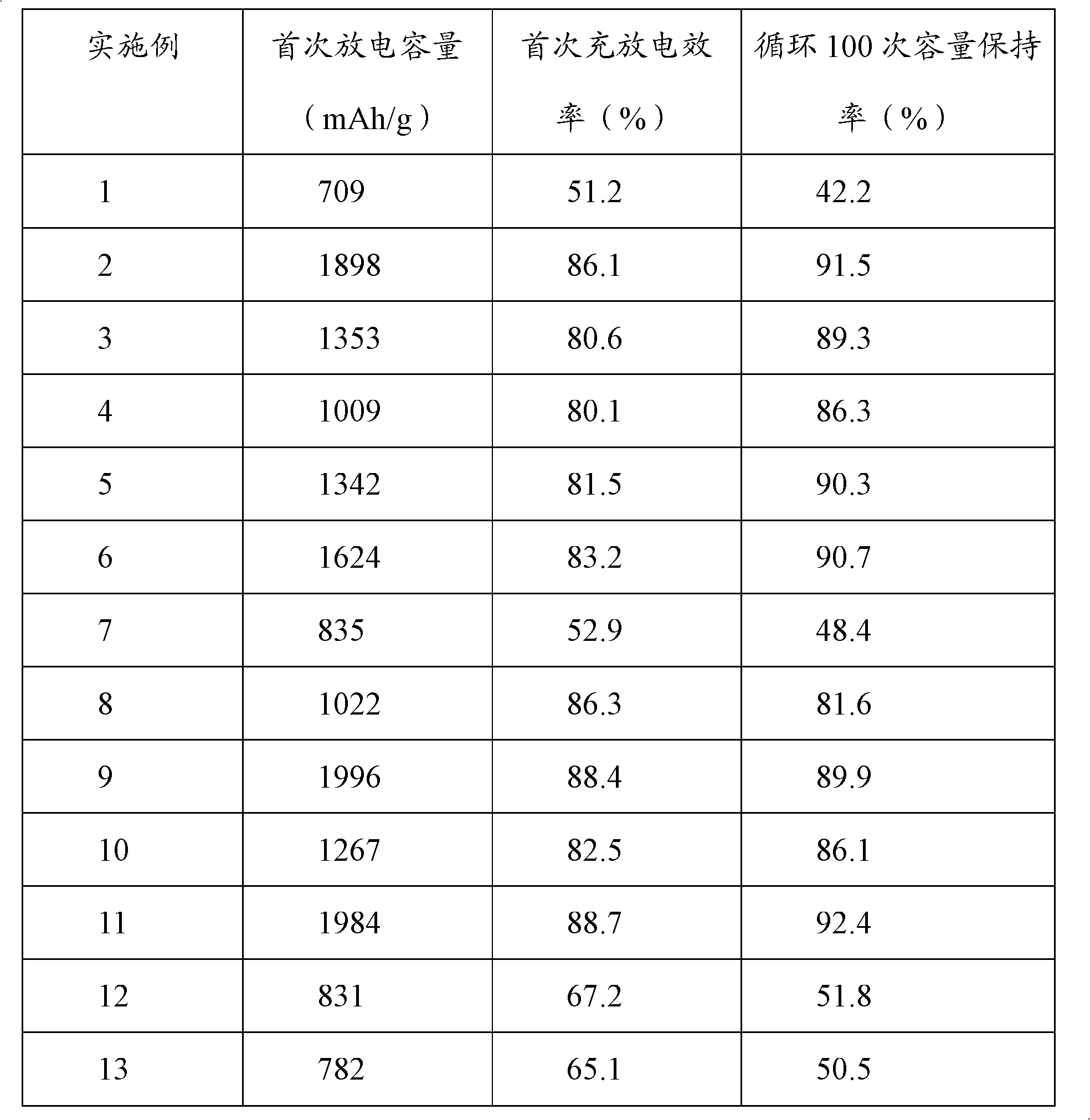

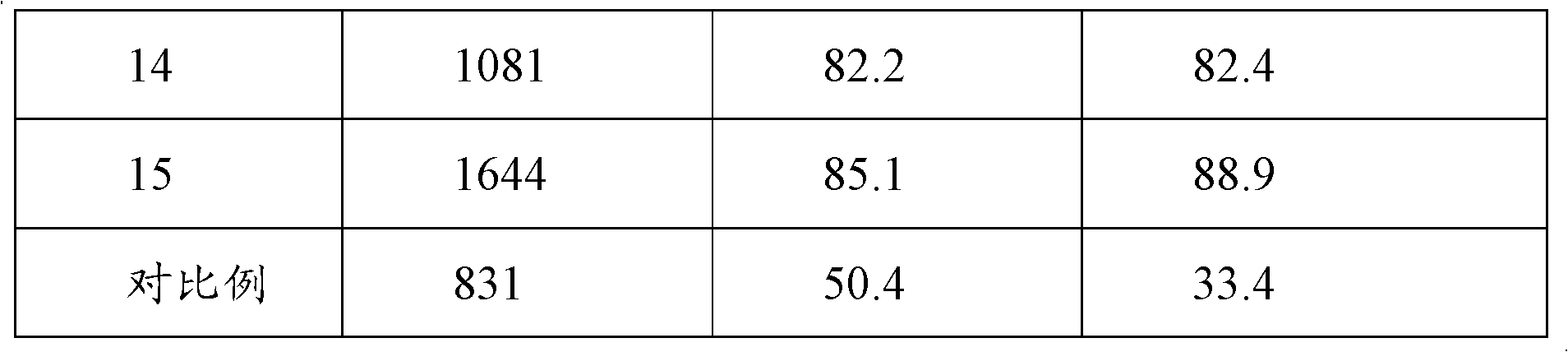

Examples

Embodiment 1

[0051] The preparation method of the porous silicon-based negative electrode composite material is divided into two steps:

[0052] The first step is to prepare porous silicon-based composites using a fixed bed, as follows: mix 100 grams of silicon powder with CuO x 15 grams of catalyst, ground evenly and packed into a fixed-bed reactor, through monochloromethane, pressure 0.3MPa, the space velocity of monochloromethane is 100h -1 , after preheating, the temperature was raised to 320° C., and the reaction was carried out for 1 day to prepare a porous silicon-based composite material.

[0053] The second step is the post-modification modification of the porous silicon-based composite material. The method is as follows: the above-mentioned porous silicon-based composite material is soaked in 1 mol / L sodium hydroxide solution for 0.5 hours, and then washed repeatedly with deionized water for 5 times. Dry in a vacuum oven at 120°C for 24 hours, weigh the silicon-based composite m...

Embodiment 2

[0055] The preparation method of the porous silicon-based negative electrode composite material is divided into two steps:

[0056] The first step is to use a stirred bed to prepare porous silicon-based composite materials. The method is as follows: mix 100 grams of silicon powder with CuO prepared by yourself x 5 grams of catalyst, ground evenly and packed into a stirred bed reactor, through monochloromethane, pressure 0.1MPa, the space velocity of monochloromethane is 100h -1 , after preheating, the temperature was raised to 300° C., and the reaction was performed for 2 days to prepare a porous silicon-based composite material.

[0057] The second step is the post-modification modification of the porous silicon-based composite material. The method is as follows: the above-mentioned porous silicon-based composite material is soaked in 2mol / L sodium hydroxide solution for 0.5 hours, and then repeatedly washed with deionized water for 5 times. Dry in a vacuum oven at 120°C for...

Embodiment 3

[0059] The preparation method of the porous silicon-based negative electrode composite material is divided into two steps:

[0060] The first step is to use a fluidized bed to prepare porous silicon-based composite materials, the method is as follows: 100 grams of silicon powder and self-prepared CuO x Catalyst 8 grams, grind evenly and pack into fluidized bed reactor, pass through monochloromethane, pressure 0.2MPa, the space velocity of monochloromethane is 100h -1, after preheating, the temperature was raised to 280° C., and the reaction was carried out for 1 day to prepare a porous silicon-based composite material.

[0061] The second step is the post-modification modification of the porous silicon-based composite material. The method is as follows: the above-mentioned porous silicon-based composite material is soaked in 1 mol / L potassium hydroxide solution for 1 hour, and then washed repeatedly with deionized water for 5 times. Dry in a vacuum oven at 120°C for 24 hours,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com