A kind of preparation method of tialsin superhard gradient coating

A gradient coating and vacuum technology, applied in the field of materials science, can solve problems such as unmet requirements and poor tool service life, and achieve the effect of improving service life, excellent mechanical properties, and excellent high temperature oxidation resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The preparation method of a kind of TiAlSiN superhard gradient coating of the present invention comprises the following steps:

[0027] (1) Sandblasting and cleaning the surface of the workpiece

[0028]Put the substrate in the sandblasting equipment, turn on the equipment to perform sandblasting on the surface of the workpiece, and remove the scale, dirt, corrosion and impurities on the surface. After sandblasting, take out the workpiece, and then use alcohol to manually clean the surface of the workpiece to remove residual substances such as oil on the surface. After the manual cleaning is completed, the workpiece is clamped and sent to an ultrasonic cleaning machine for automatic cleaning by ultrasonic waves. After the ultrasonic cleaning is completed and the workpiece is dried, the workpiece is clamped and sent into the preheated coating furnace chamber, and the program is started. After the furnace chamber is evacuated and the substrate temperature reaches 400-500...

Embodiment 2

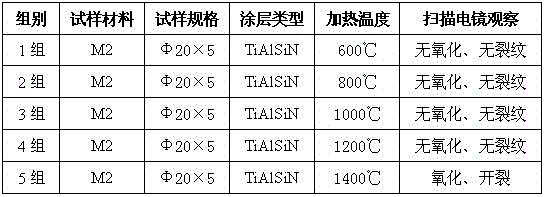

[0042] Example 2 High temperature resistance experiment of TiAlSiN

[0043] Select 5 groups of high-speed steel (brand M2) samples, 5 pieces in each group (each piece specification Φ20×5), polish one side of the sample, and after cleaning the whole sample, apply TiAlSiN coating according to the above process, one side of the coating The thickness is 3 microns. Put the prepared coating samples into the heating furnace in groups, set the temperature of the heating furnace to 600°C, 800°C, 1000°C, 1200°C and 1400°C respectively, and then cut the samples with slow wire walking , Observe the cross-section of the coating part under the scanning electron microscope, and the results are shown in Table 1.

[0044] Table 1 SEM observation results of high temperature experiment

[0045]

Embodiment 3

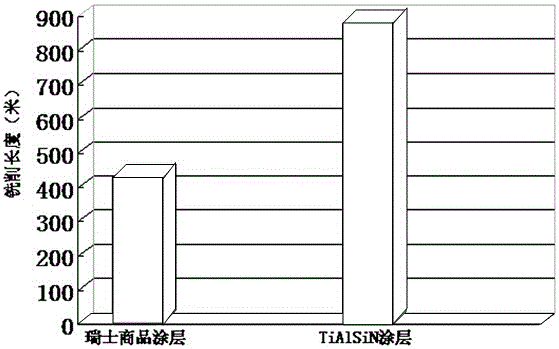

[0046] Example 3 High hardness cutting experiment of TiAlSiN coating

[0047] Tool: Carbide ball end milling cutter, Φ10mm;

[0048] Processed material: Japanese Daido mold steel DC53, hardness HRC60;

[0049] Cutting parameter: v=320m / min;

[0050] f=0.2mm / r;

[0051] a p =0.3mm;

[0052] VB=0.12mm;

[0053] Cooling method: dry cutting;

[0054] Reference coating: Swiss commercial coating;

[0055] In this embodiment, a cemented carbide ball end milling cutter is selected, and a high-hardness milling test is carried out through a TiAlSiN coating. At present, there is a Swiss company on the market that specializes in the preparation of high-hardness cutting coatings for milling cutters. For comparison, the coating produced by this Swiss company is specially selected for comparison with the TiAlSiN coating. The coating produced by the Swiss company is named "Swiss commodity coating". Experimental results such as figure 1 shown. It can be seen from the experimental re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com