Composite dielectric ceramic, preparation method thereof and microwave filter

A technology of microwave filters and dielectric ceramics, which is applied in vacuum evaporation plating, coating, sputtering plating, etc., can solve the problems of unstable performance, low bonding force, and poor bonding force of microwave filters, and achieve the goal of manufacturing The method conditions are controllable, the cost is low, and the effect of stress is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

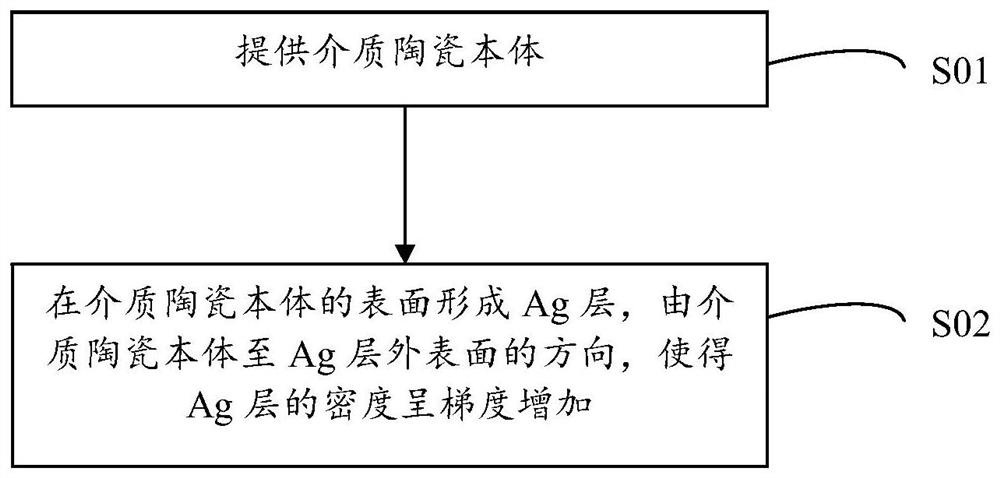

[0043] Correspondingly, the embodiment of the present application also provides the preparation method of the composite dielectric ceramic in the above embodiment of the application. The preparation method technological process of this composite dielectric ceramic is as follows figure 1 shown, including the following steps:

[0044] Step S01: providing a dielectric ceramic body;

[0045] Step S02: forming an Ag layer on the surface of the dielectric ceramic body, the density of the Ag layer increases in a gradient from the dielectric ceramic body to the outer surface of the Ag layer.

[0046] Wherein, the dielectric ceramic body in step S01 is the dielectric ceramic body mentioned above. In an embodiment, the dielectric ceramic body is a microwave dielectric ceramic body of a microwave filter. Its shape can be according to the shape commonly used in microwave filters or the improved shape.

[0047] Before the Ag layer is formed on the surface of the dielectric ceramic body...

Embodiment 1

[0062] This embodiment provides a microwave filter and a preparation method thereof. The microwave filter includes a microwave dielectric ceramic body and an Ag layer deposited on the surface of the microwave dielectric ceramic body.

[0063] The preparation method of microwave filter comprises the steps:

[0064] S1: Provide dielectric ceramic body:

[0065] S11: Carry out vibration grinding and ultrasonic cleaning on the dielectric ceramics, the vibration grinding particles are alumina balls with a diameter of 4 mm; the ultrasonic cleaning solvents are acetone and absolute ethanol, and the cleaning time is 30 minutes;

[0066] S12: Dry the dielectric ceramic after ultrasonic cleaning, the drying temperature is 120°C, and the drying time is 40 minutes;

[0067] S2: Put the dielectric ceramic into the magnetron sputtering chamber, and when it reaches 5×10 -4 After Pa background vacuum degree, argon gas is introduced and substrate heating is turned on, and argon plasma is ge...

Embodiment 2

[0069] This embodiment provides a microwave filter and a preparation method thereof. The microwave filter includes a microwave dielectric ceramic body and an Ag layer deposited on the surface of the microwave dielectric ceramic body.

[0070] The preparation method of microwave filter comprises the steps:

[0071] S1: Provide dielectric ceramic body:

[0072]S11: Carry out vibration grinding and ultrasonic cleaning on the dielectric ceramics, the vibration grinding particles are alumina balls with a diameter of 4 mm; the ultrasonic cleaning solvents are acetone and absolute ethanol, and the cleaning time is 30 minutes;

[0073] S12: Dry the dielectric ceramic after ultrasonic cleaning, the drying temperature is 150°C, and the drying time is 40 minutes;

[0074] S2: Put the dielectric ceramic into the magnetron sputtering cavity, and when it reaches 6×10 -4 After the Pa background vacuum degree, argon gas is introduced and the substrate is heated, and argon plasma is generat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com