Preparation of a transition metal oxide cathode material and its application in sodium-ion batteries

A technology of sodium ion batteries and transition metals, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems that it is difficult to directly prepare layered transition metal oxide cathode materials, and achieve excellent rate performance and cycle performance. Effects of discharge capacity and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

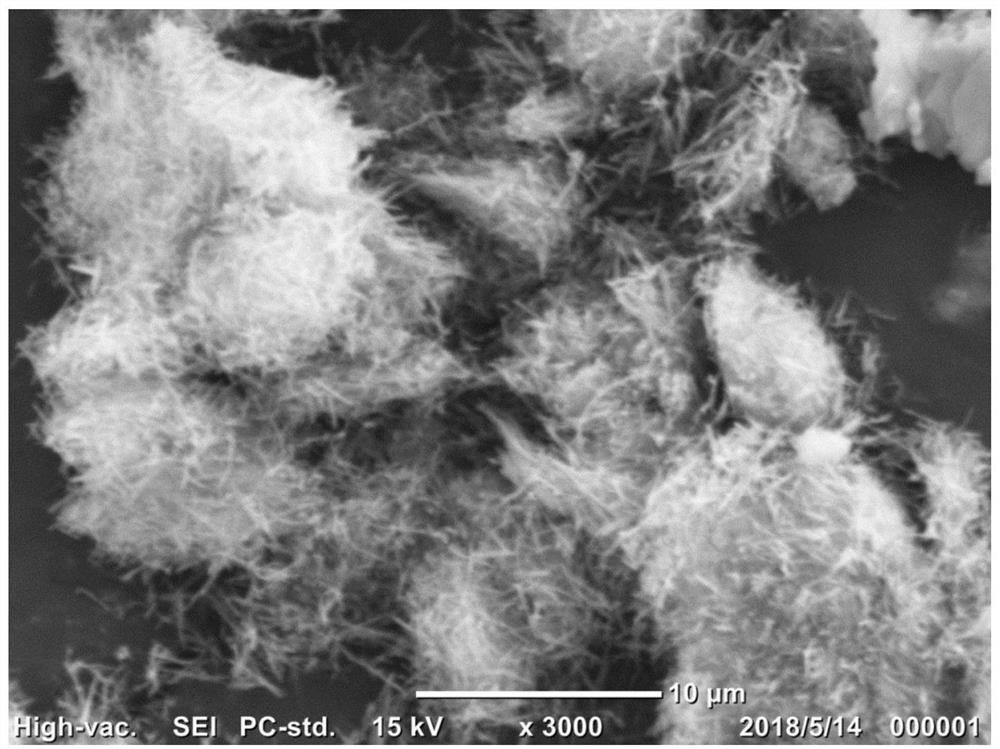

[0020] Embodiment 1: (MnO 2 Preparation of Na by Nanowire Template Method 2 / 3 Fe 1 / 2 Mn 1 / 2 O 2 Nanowires)

[0021] Weigh 0.822g potassium permanganate and 0.278g ammonium chloride, add them to a 250mL hydrothermal kettle, add 195ml deionized water, and react at 140°C for 36h. The obtained mixed solution was centrifuged, washed three times with deionized water and ethanol, and then placed in an oven at 120 °C for 8 h to obtain MnO 2 Nanowires. The obtained MnO was mixed in a molar ratio of 4:3:3 (Na:Fe:Mn) 2 The nanowires were dispersed into a mixed solution of ferric nitrate and sodium carbonate, a stirrer was added, the solvent was evaporated in a water bath at 80°C, and then placed in an oven at 100°C for 12 hours to obtain precursor A. The precursor A was pre-sintered at 350 °C for 2 h in an air atmosphere, and sintered at a high temperature of 900 °C for 12 h. After cooling, the cathode material Na was obtained. 2 / 3 Fe 1 / 2 Mn 1 / 2 O 2 nanowires, as attached fig...

Embodiment 2

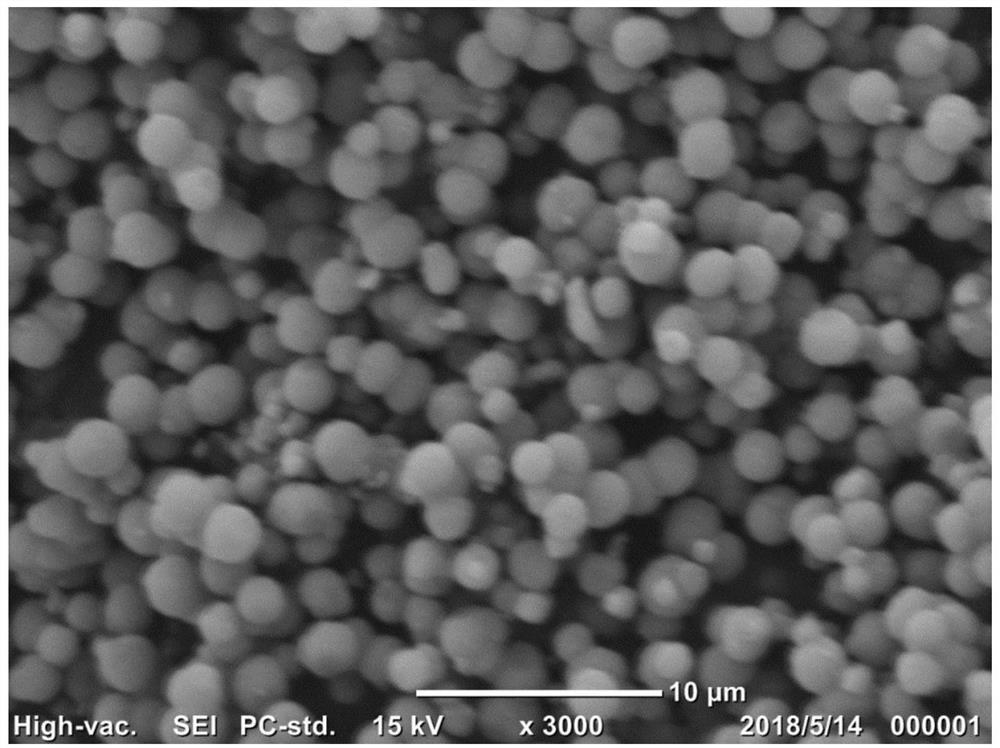

[0022] Embodiment 2: (MnO 2 Preparation of Na by Microsphere Template Method 2 / 3 Fe 1 / 2 Mn 1 / 2 O 2 Microspheres)

[0023] Weigh 0.507g of manganese sulfate and 2.371g of ammonium bicarbonate, dissolve them into 210ml of deionized water, add 21ml of ethanol to the manganese sulfate solution, quickly pour the ammonium bicarbonate solution into the manganese sulfate solution, and stir at room temperature for 3 hours. The obtained suspension was centrifuged, washed three times with deionized water and ethanol, and then placed in an oven at 100 °C for 12 h to obtain MnCO 3 Microspheres. The resulting MnCO 3 The microspheres were sintered at 400 °C for 5 h to obtain MnO 2 Microspheres. The obtained MnO was mixed in a molar ratio of 4:3:3 (Na:Fe:Mn) 2 The microspheres were dispersed into a mixed solution of ferric nitrate and sodium carbonate, a stirrer was added, the solvent was evaporated in a water bath at 80°C, and then placed in an oven at 100°C for 12 hours to obtain p...

Embodiment 3

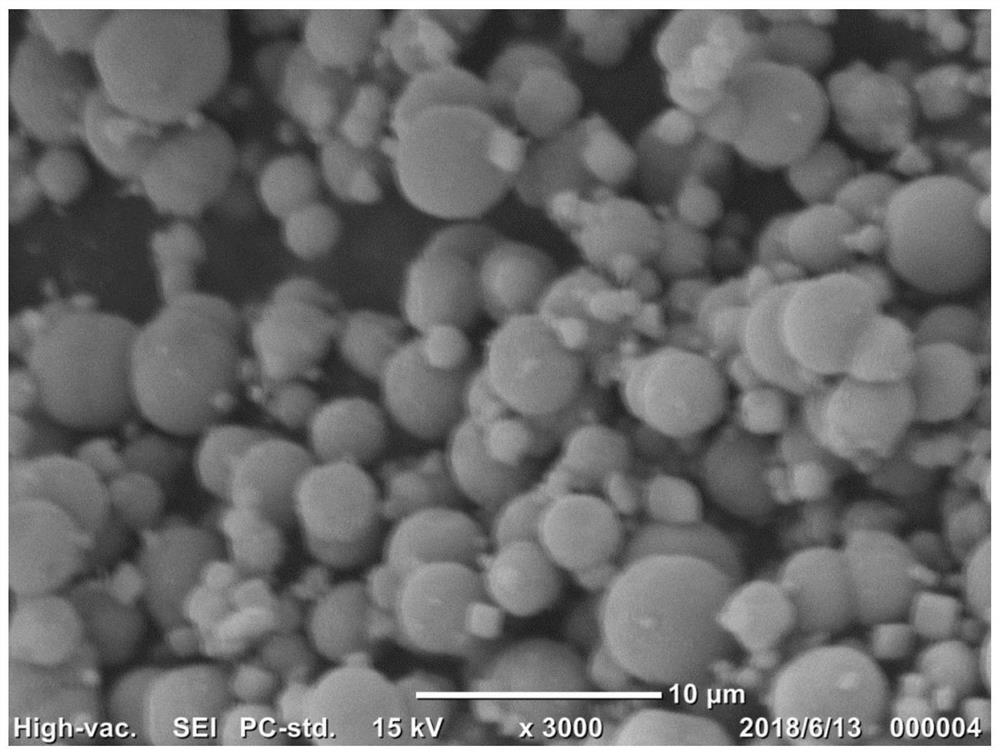

[0024] Embodiment 3: (Fe 3 O 4 Preparation of Na by Microsphere Template Method 2 / 3 Fe 1 / 2 Mn 1 / 2 O 2 Microspheres)

[0025] Weigh 0.947g of ferric chloride, 2.46g of urea, 2.5g of ascorbic acid, and 2g of PVP (molecular weight: 40000), add them to a 100mL hydrothermal kettle, add 80ml of deionized water, and react at 160°C for 6h. The obtained mixed solution was centrifuged, washed three times with deionized water and ethanol, and then placed in an oven at 60 °C for 8 h to obtain FeCO 3 Microspheres. The resulting MnCO 3

[0026] The microspheres were sintered at 400 °C for 5 h to obtain Fe 3 O 4 Microspheres. The obtained Fe was converted into a molar ratio of 4:3:3 (Na:Fe:Mn) 3 O 4 The microspheres were dispersed into a mixed solution of manganese acetate and sodium carbonate, a stirrer was added, the solvent was evaporated in a water bath at 80°C, and then placed in an oven at 100°C for 12 hours to obtain precursor A. The precursor A was pre-sintered at 350 °C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com