Low-contraction, high-temperature-resistant, and high-strength resin concrete and preparation method thereof

A high-strength resin, high-temperature-resistant technology, applied in the field of concrete, can solve the problems of poor high temperature resistance and low early curing shrinkage of resin concrete, and achieve the effects of prolonging curing time, solving volume instability, and increasing stress relaxation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with specific embodiments.

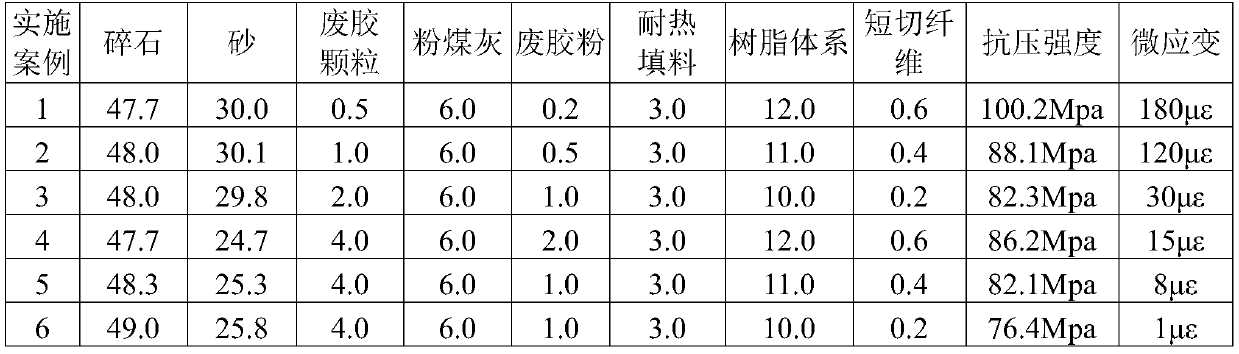

[0019] A low-shrinkage and high-temperature-resistant high-strength resin concrete of the present invention is composed of the following components by weight: resin system (including resin, curing agent, accelerator) 8.0%-15.0%, gravel 45.0%-51.0%, sand 20.0% to 38.0%, fly ash 2.0% to 7.0%, heat-resistant filler 0.5% to 3.0%, waste rubber particles 0.0% to 5.0%, waste rubber powder 0.2% to 2.0%, and chopped fiber 0.1% to 6.0% %. The resin is a high-temperature-resistant resin with a heat-resistant deformation temperature > 140°C; the maximum particle size of the stones is no more than 30mm, and the gradation is good; the sand is river sand and machine-made sand (the parent rock is generally granite , basalt) or one or more of desalinated sea sand, etc., and the gradation is good; the fly ash is Class II fly ash and Class I fly ash. The high temperature resistant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com