Method for continuously measuring change of shrinkage strain ratio of titanium alloy pipe

A shrinkage strain, titanium alloy technology, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve problems such as error in analysis results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] This embodiment is a method for continuously measuring the shrinkage strain ratio of titanium alloy pipes, and the specific steps are as follows:

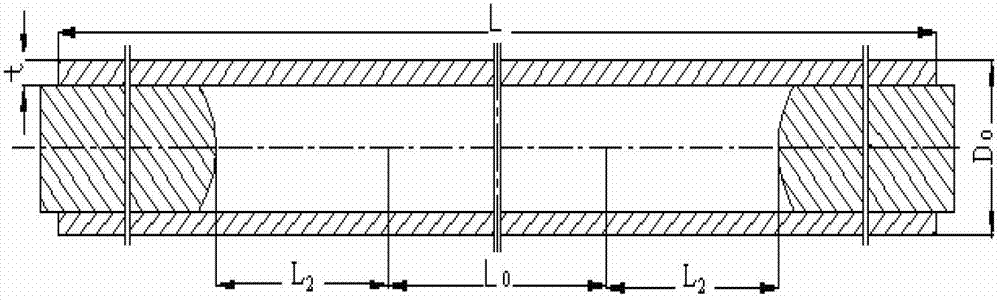

[0042] Step 1, making a tube sample. Sampling according to GB / T228-2002 tensile standard for pipes with stopper rods. The length of the tube sample is 130 mm, the wall thickness is 0.5 mm, the outer diameter is 6 mm, and the inner diameter is 5 mm. Tube samples such as figure 1 shown.

[0043] Two gauge points are determined on the tube sample. When determining the two gauge points, take the center of the length direction of the pipe sample as the reference, and take 25mm to both sides of the center as gauge point A and gauge point B respectively, and the gauge point A and gauge point B are marked with dashed lines. The gauge length between the gauge point A and the gauge point B is the gauge length of the pipe sample, and the length is L 0 . In this example, L 0 = 50mm.

[0044] A pipe plug made of 45# steel is in...

Embodiment 2

[0077] This embodiment is a method for continuously measuring the shrinkage strain ratio of titanium alloy pipes, and the specific steps are as follows:

[0078] Step 1, making a tube sample. Sampling according to GB / T228-2002 tensile standard for pipes with stopper rods. The length of the tube sample was 154 mm, the wall thickness was 0.6 mm, the outer diameter was 8 mm, and the inner diameter was 6.8 mm. Tube samples such as figure 1 shown.

[0079] Two gauge points are determined on the tube sample. When determining the two gauge points, take the center of the length direction of the pipe sample as the reference, and take 25mm to both sides of the center as gauge point A and gauge point B respectively, and the gauge point A and gauge point B are marked with dashed lines. The gauge length between the gauge point A and the gauge point B is the gauge length of the pipe sample, and the length is L 0 . In this example, L 0 = 50mm.

[0080] A pipe plug made of 45# steel...

Embodiment 3

[0093] This embodiment is a method for continuously measuring the shrinkage strain ratio of titanium alloy pipes, and the specific steps are as follows:

[0094] Step 1, making a tube sample. Sampling according to GB / T228-2002 tensile standard for pipes with stopper rods. The length of the tube sample was 180 mm, the wall thickness was 0.9 mm, the outer diameter was 12 mm, and the inner diameter was 10.2 mm. Tube samples such as figure 1 shown.

[0095] Two gauge points are determined on the tube sample. When determining the two gauge points, take the center of the length direction of the pipe sample as the reference, and take 25mm to both sides of the center as gauge point A and gauge point B respectively, and the gauge point A and gauge point B are marked with dashed lines. The gauge length between the gauge point A and the gauge point B is the gauge length of the pipe sample, and the length is L 0 . In this example, L 0= 50mm.

[0096] A pipe plug made of 45# stee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com