Full-particle size ultrahigh-performance concrete composition

A concrete composition, ultra-high-performance technology, applied in the field of concrete composition, full-size ultra-high-performance concrete composition, can solve the problem of large shrinkage and deformation of cementitious materials, low water-binder ratio of high-performance concrete, and poor rheology And other problems, to achieve the effect of controllable rheological properties, good working performance and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

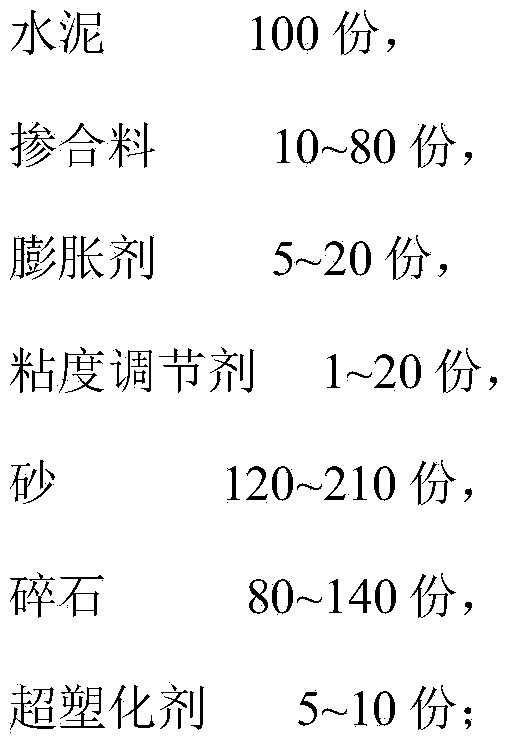

Method used

Image

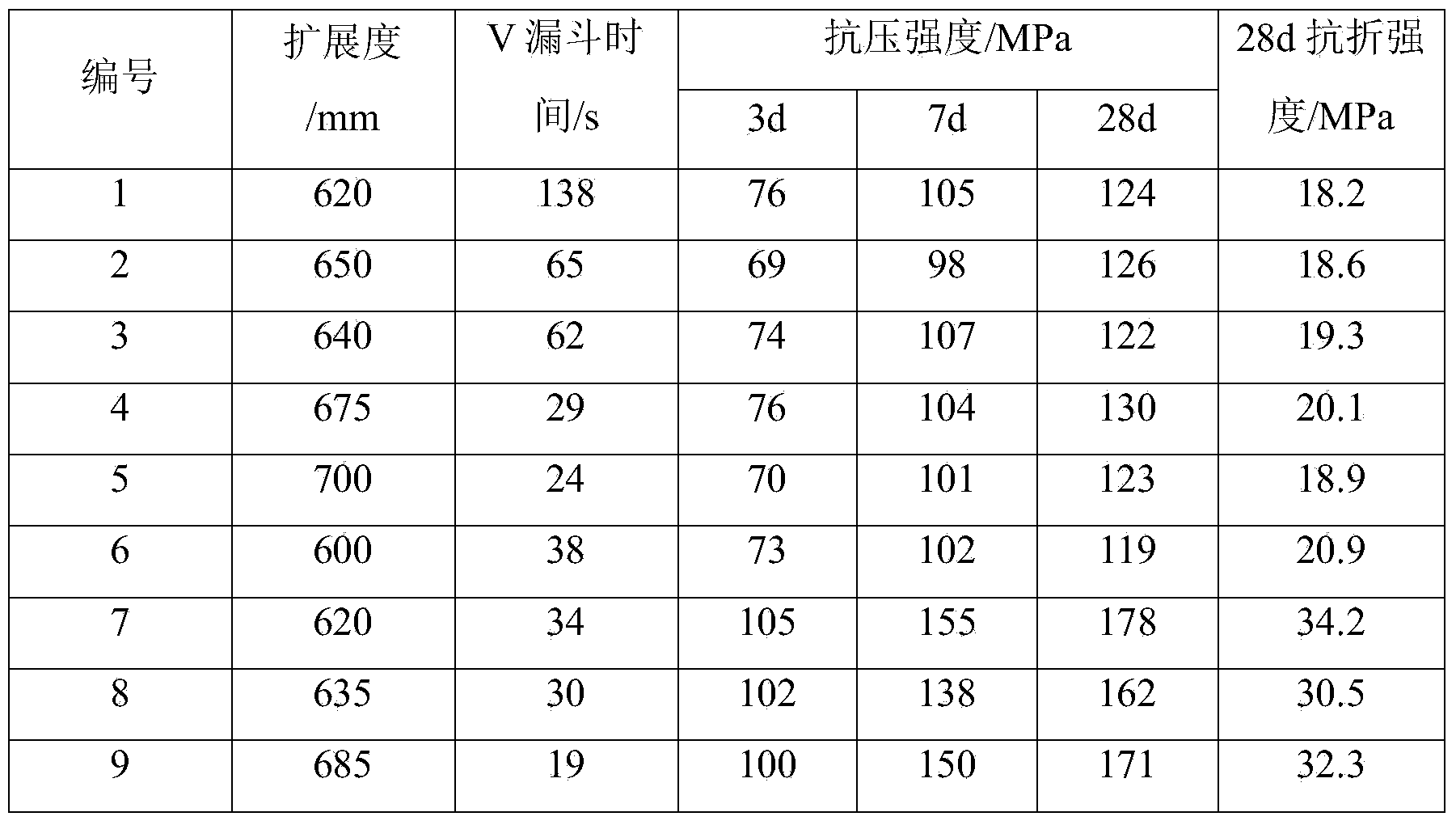

Examples

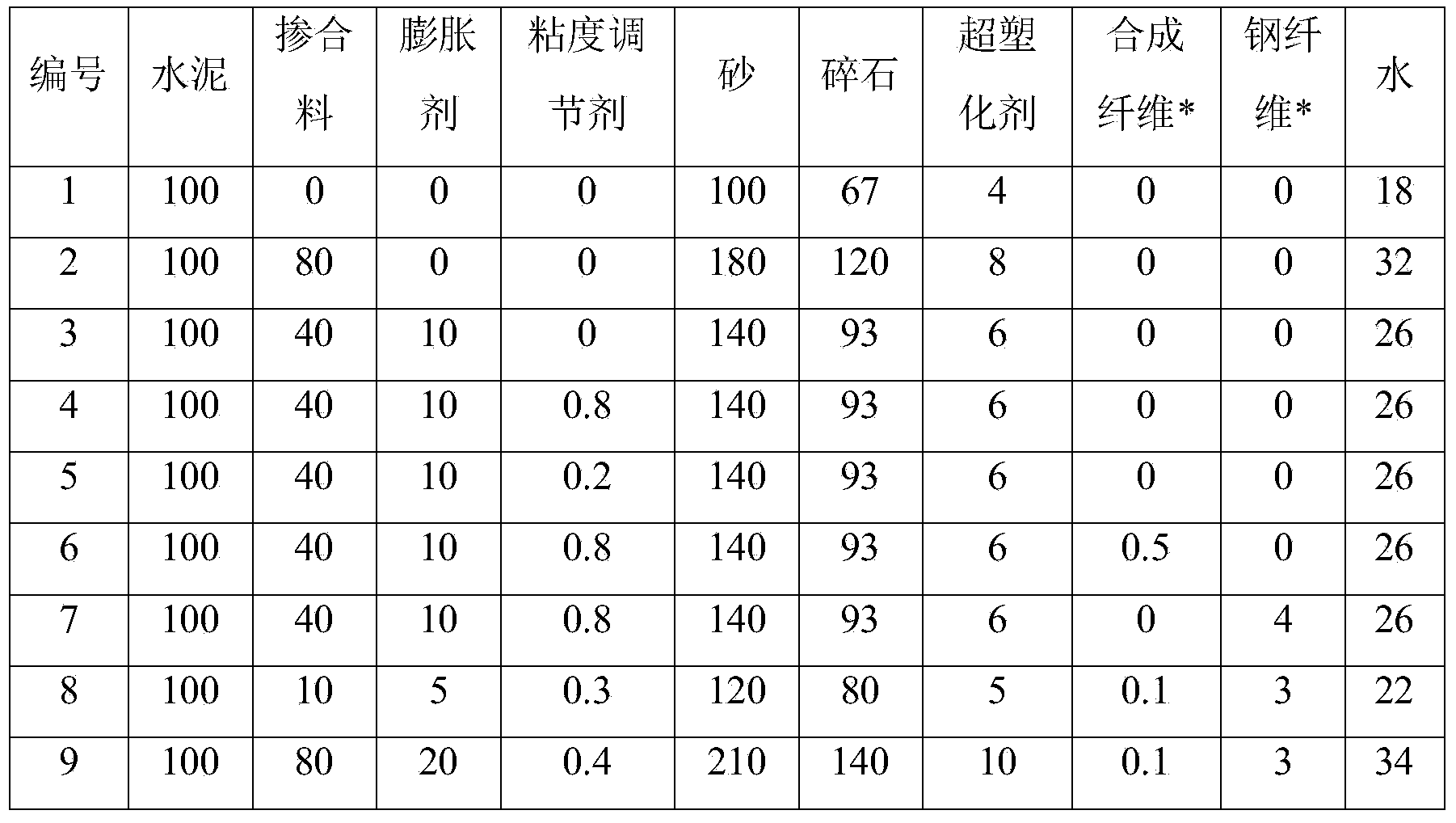

Embodiment 1

[0049] Embodiment 1 is the benchmark concrete, without adding other components such as admixtures and expansion agents, using pure cement as the cementitious material, sand using river sand, crushed stone using basalt, and superplasticizer using powder polycarboxylate reducing agent. Aqua with no added fiber. After the above materials are mixed, they are packaged, and the above-mentioned ratio of water is directly added to the site for mixing to obtain full-size ultra-high performance concrete.

Embodiment 2

[0050] In Example 2, the admixture is composed of superfine fly ash and silica fume in a ratio of 7:3, river sand is used for sand, basalt is used for crushed stone, and powdered polycarboxylate water reducer is used as superplasticizer. After the above materials are mixed, they are packaged, and the above-mentioned ratio of water is directly added to the site for mixing to obtain full-size ultra-high performance concrete.

Embodiment 3

[0051]In Example 3, the admixture is composed of ultrafine mineral powder and silica fume in a ratio of 8:2, the expansion agent is calcium oxide, the sand is river sand, the crushed stone is diabase, and the superplasticizer is powder polycarboxylate. Acid water reducing agent, polyvinyl alcohol fiber is used for synthetic fiber. After the above materials are mixed, they are packaged, and the above-mentioned ratio of water is directly added to the site for mixing to obtain full-size ultra-high performance concrete.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com