Automatic control system of gas jet impact drying machine

An automatic control system, gas jet technology, applied in the direction of drying solid materials, drying, lighting and heating equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

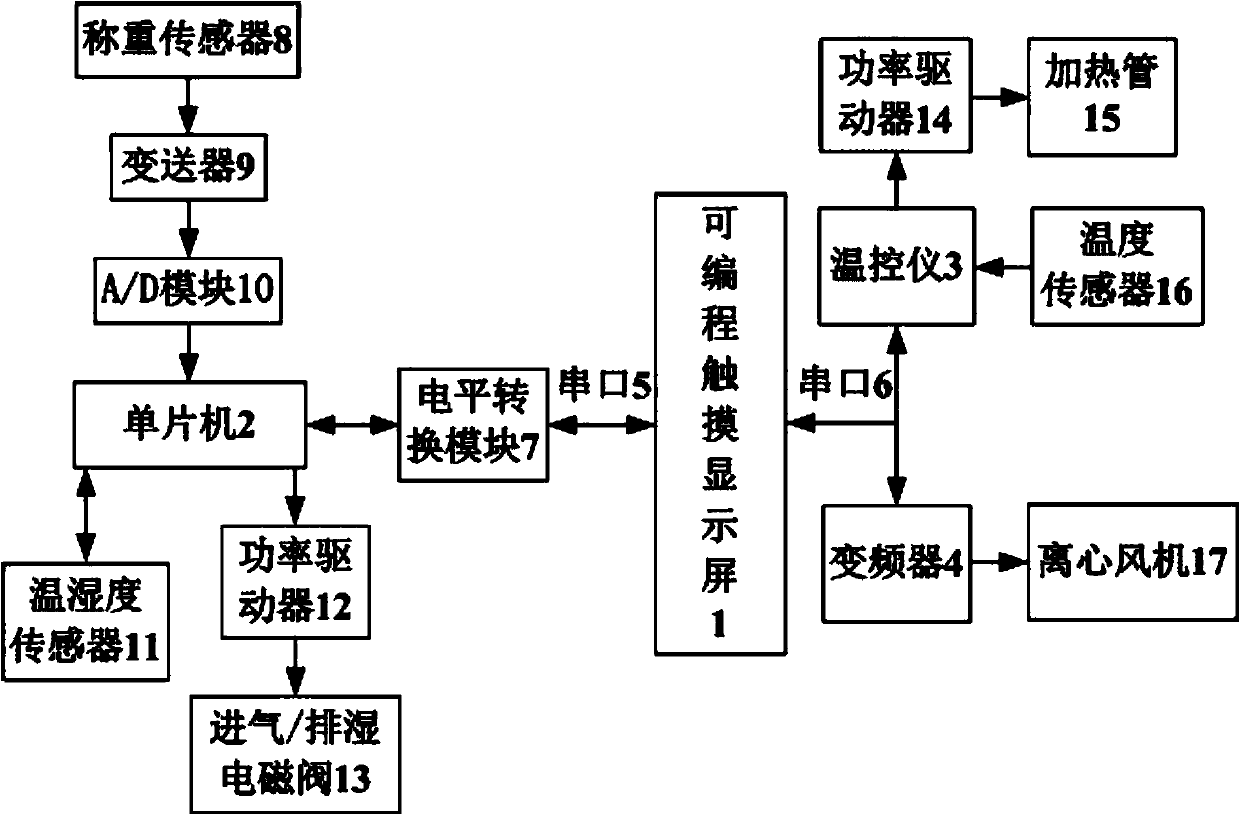

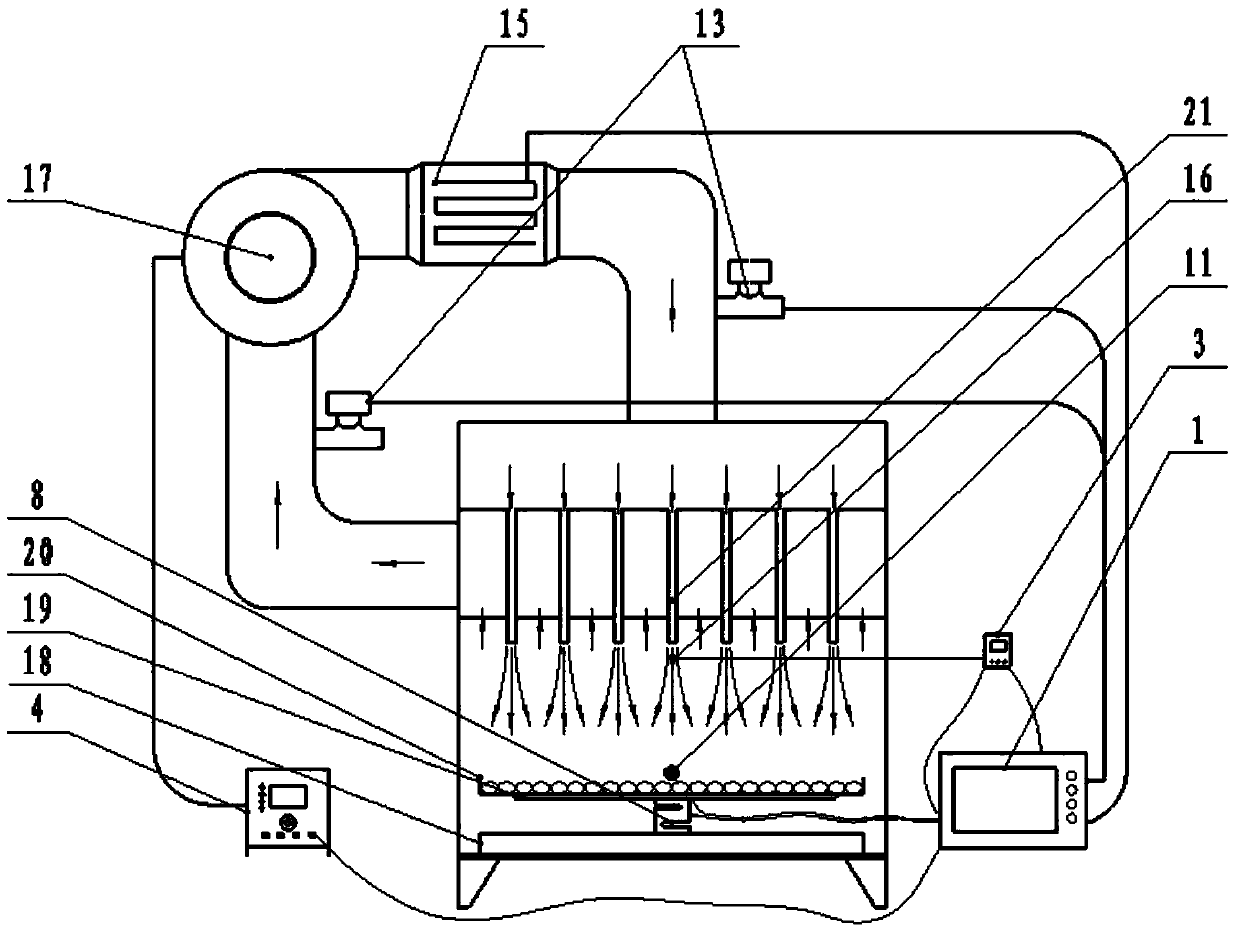

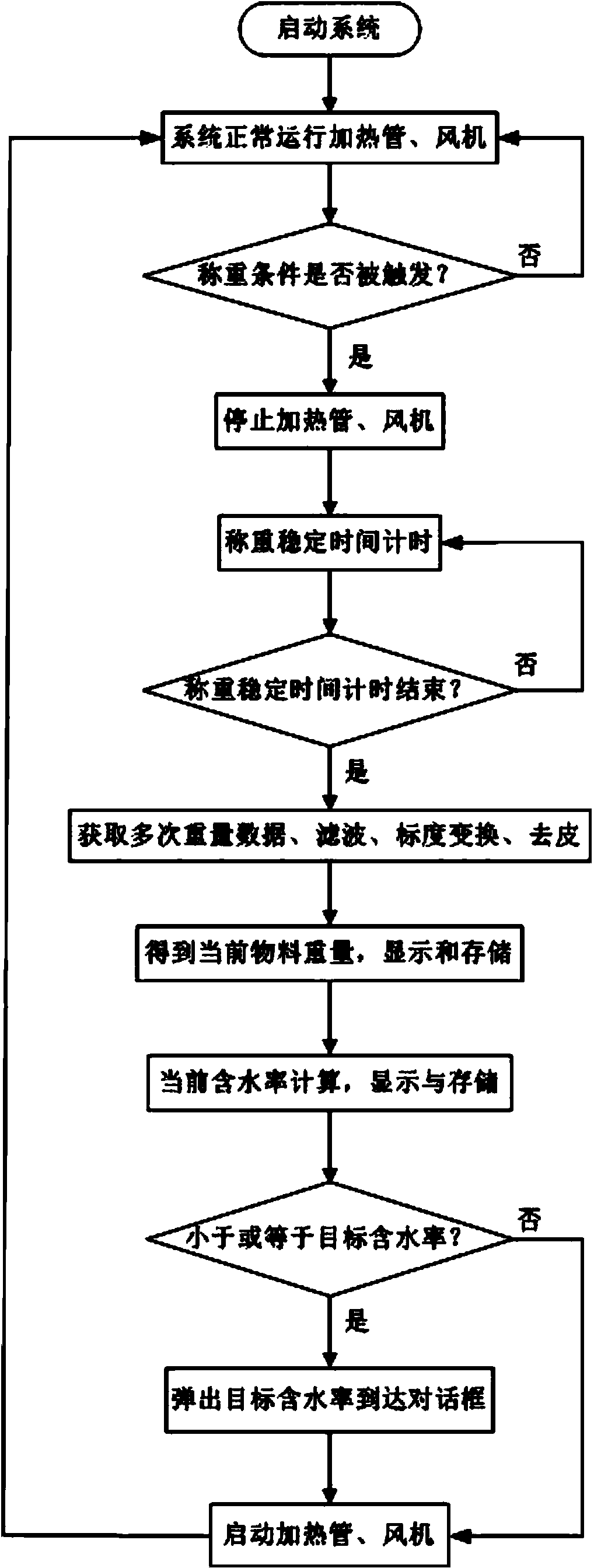

[0041] figure 1 It is a functional block diagram of the automatic control system of the gas jet impingement dryer of the present invention, including a programmable touch display 1, wherein the programmable touch display 1 includes a man-machine interface and a background program module, so that the programmable touch display 1 is While the system provides man-machine interaction function, it also becomes the control core of the system; among them, the system man-machine interface is used for parameter setting, such as multi-stage drying parameter setting, automatic weighing parameter setting, and is used for real-time display of various data during the drying process , such as temperature and humidity data, wind speed data, material weight data, and moisture content data, used to display the status of each functional part of the dryer, such as dehumidificati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com