Method for producing diammonium phosphate by concentrating acid slime, and secondary ammoniation reactor

An ammonification reactor and ammonification reaction technology, applied in ammonium orthophosphate fertilizer, alkaline orthophosphate fertilizer, phosphate, etc., can solve the problem of high moisture content in concentrated slurry, high drying energy consumption, and inability to add ammonia, etc. problems, and achieve the effects of environmental protection, remarkable energy saving effect and improved utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The phosphate rock used in this embodiment contains P 2 o 5 26.81%, Fe 2 o 3 2.31%, Al 2 o 3 3.04%, MgO 2.27%; dihydrate wet-process phosphoric acid prepared from this phosphate rock contains 22% P 2 o 5 , the above percentages are mass percentages.

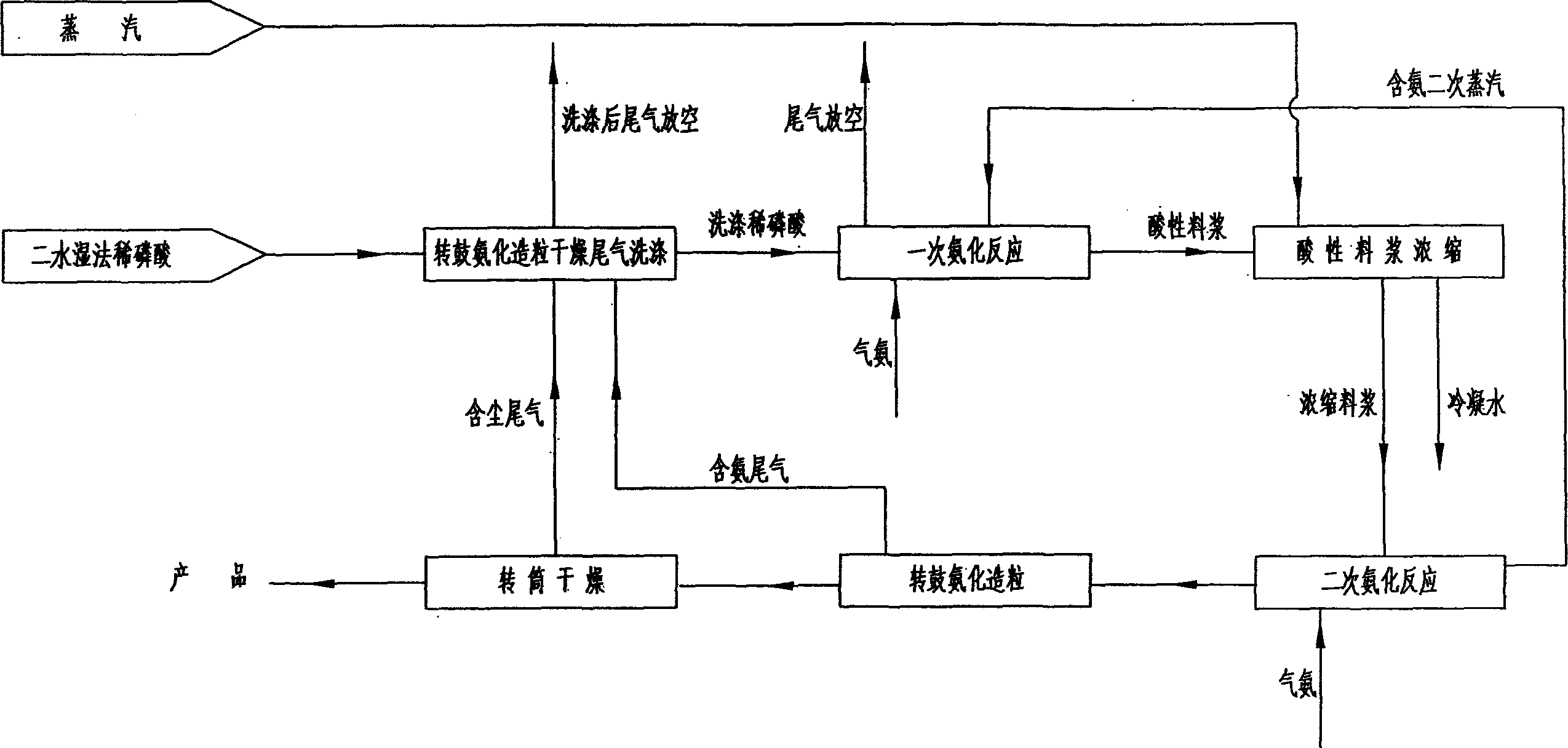

[0026] The technological process of this embodiment is as figure 1 As shown, the following steps are followed in sequence:

[0027] 1. Primary ammoniation reaction

[0028] The dihydrate wet-process dilute phosphoric acid enters the primary ammoniation reaction device through the washing device for primary ammoniation reaction with gaseous ammonia to prepare acidic ammonium phosphate slurry with a neutralization degree of 0.6. The washing device is a horizontal Venturi scrubber, and the primary ammoniation reaction device is a tank-type full-mixed tank reactor.

[0029] 2. Concentration of acid slurry

[0030] The concentration of the acidic slurry adopts double-effect concentration, and the device used is a ...

Embodiment 2

[0041]The phosphate rock used in this embodiment contains P 2 o 5 32.15%, Fe 2 o 3 1.24%, Al 2 o 3 1.14%, MgO 1.35%; dihydrate wet-process phosphoric acid prepared from this phosphate rock contains 26% P 2 o 5 , the above percentages are mass percentages.

[0042] The technological process of this embodiment is as figure 1 As shown, the following steps are followed in sequence:

[0043] 1. Primary ammoniation reaction

[0044] The dihydrate wet-process dilute phosphoric acid enters the primary ammoniation reaction device through the washing device for primary ammoniation reaction with gaseous ammonia to prepare acidic ammonium phosphate slurry with a neutralization degree of 0.85. The washing device is a horizontal Venturi scrubber, and the primary ammoniation reaction device is a tank-type full-mixed tank reactor.

[0045] 2. Concentration of acid slurry

[0046] The concentration of the acidic slurry adopts double-effect concentration, and the device used is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com