Multifunctional finishing liquor formula for foam finishing and application process

A foam finishing, multi-functional technology, applied in fiber processing, textiles and papermaking, etc., can solve the problems of increasing production costs of production enterprises, and achieve the effect of increasing value and grade, improving quality of life, and excellent environmental performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

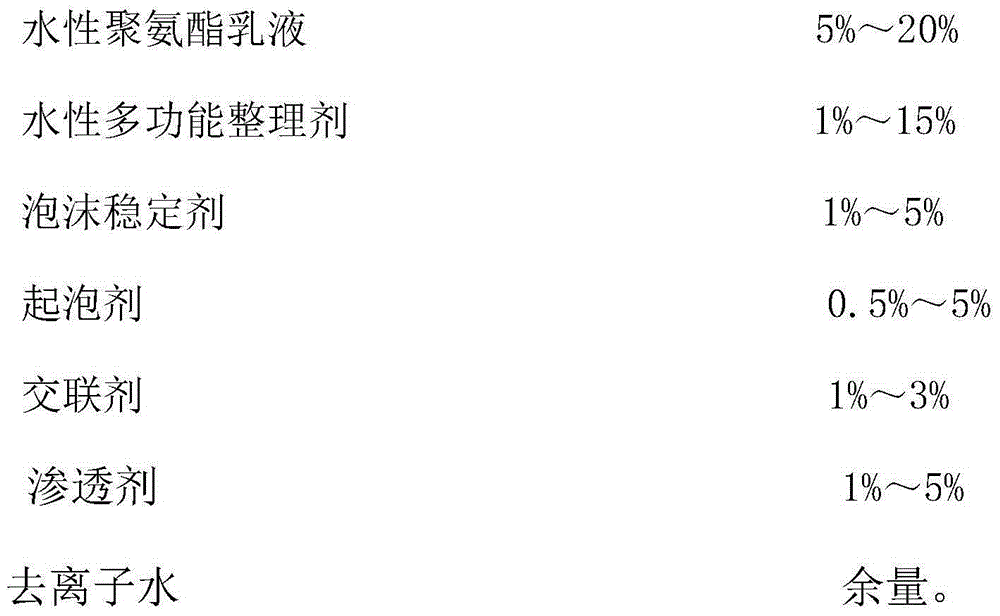

[0022] To formulate foam multifunctional finishing liquid, the ratio of raw materials is as follows:

[0023]

[0024]

[0025] Add the formula amount of raw materials into the container one by one, stir evenly with a dispersing mixer, and the mixing speed of the dispersing mixer is 800 rpm to obtain a foam multifunctional finishing liquid;

[0026] The formulated foam multifunctional finishing liquid is made into 10 times finishing foam through the intelligent dynamic foam generator, and the finishing foam is evenly applied to the fabric or synthetic leather to be finished, using an intelligent constant pressure foam jet applicator or a knife Apply the finishing foam evenly to the fabric or synthetic leather to be finished by coating, rolling, roller coating, etc., so that the foam will quickly burst when it contacts the fabric and penetrate into the fabric fibers;

[0027] The finished fabric or synthetic leather is dried in an oven, multi-stage temperature control is implemented, ...

Embodiment 2

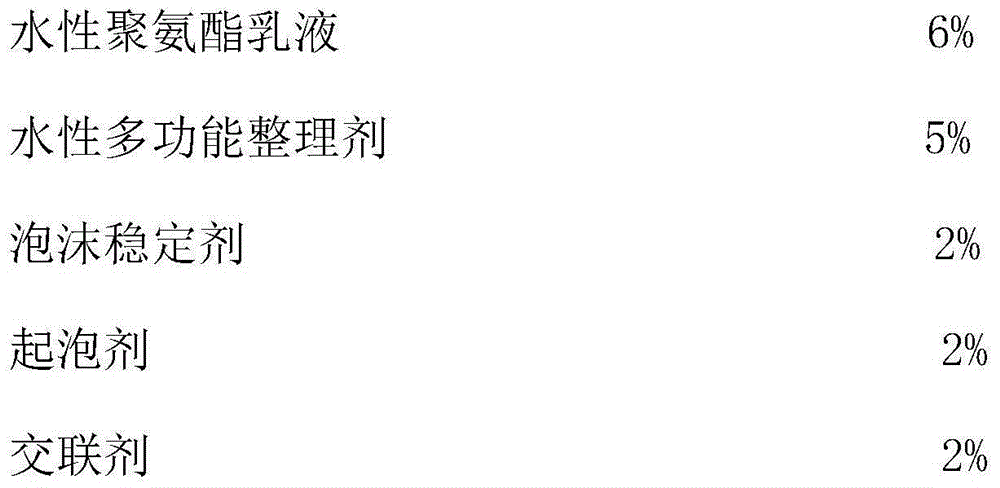

[0029] To formulate foam multifunctional finishing liquid, the ratio of raw materials is as follows:

[0030]

[0031] Add the formula amount of raw materials in the container in turn, stir evenly with a dispersing mixer, and the mixing speed of the dispersing mixer is 1000 rpm to obtain a foam multifunctional finishing liquid;

[0032] The prepared foam multifunctional finishing liquid is made into 15 times finishing foam through the intelligent dynamic foam generator, and the finishing foam is evenly applied to the fabric or synthetic leather that needs finishing, using an intelligent constant pressure foam jet applicator or a knife Apply the finishing foam evenly to the fabric or synthetic leather to be finished by coating, rolling, roller coating, etc., so that the foam will quickly burst when it contacts the fabric and penetrate into the fabric fibers;

[0033] The finished fabric or synthetic leather is dried in an oven, multi-stage temperature control is implemented, and the t...

Embodiment 3

[0035] To formulate foam multifunctional finishing liquid, the ratio of raw materials is as follows:

[0036]

[0037] Add the formula amount of raw materials into the container in sequence, stir evenly with a dispersing mixer, the stirring speed of the dispersing mixer is 1400 rpm, to obtain a foam multifunctional finishing liquid;

[0038] The prepared foam multifunctional finishing liquid is made into a 20-fold finishing foam through an intelligent dynamic foam generator, and the finishing foam is evenly applied to the fabric or synthetic leather to be finished, using an intelligent constant pressure foam jet applicator or a knife Apply the finishing foam evenly to the fabric or synthetic leather to be finished by coating, rolling, roller coating, etc., so that the foam will quickly burst and penetrate into the fabric fibers when it contacts the fabric or synthetic leather;

[0039] The finished fabric or synthetic leather is dried in an oven, multi-stage temperature control is im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com