Continuous production method and apparatus for alpha semi-water gypsum

A technology of hemihydrate gypsum and a production method, which is applied in the field of gypsum processing, can solve the problems of large equipment investment, high labor intensity, complicated operation, etc., and achieves the effects of reducing investment, saving energy consumption, and simplifying technological process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

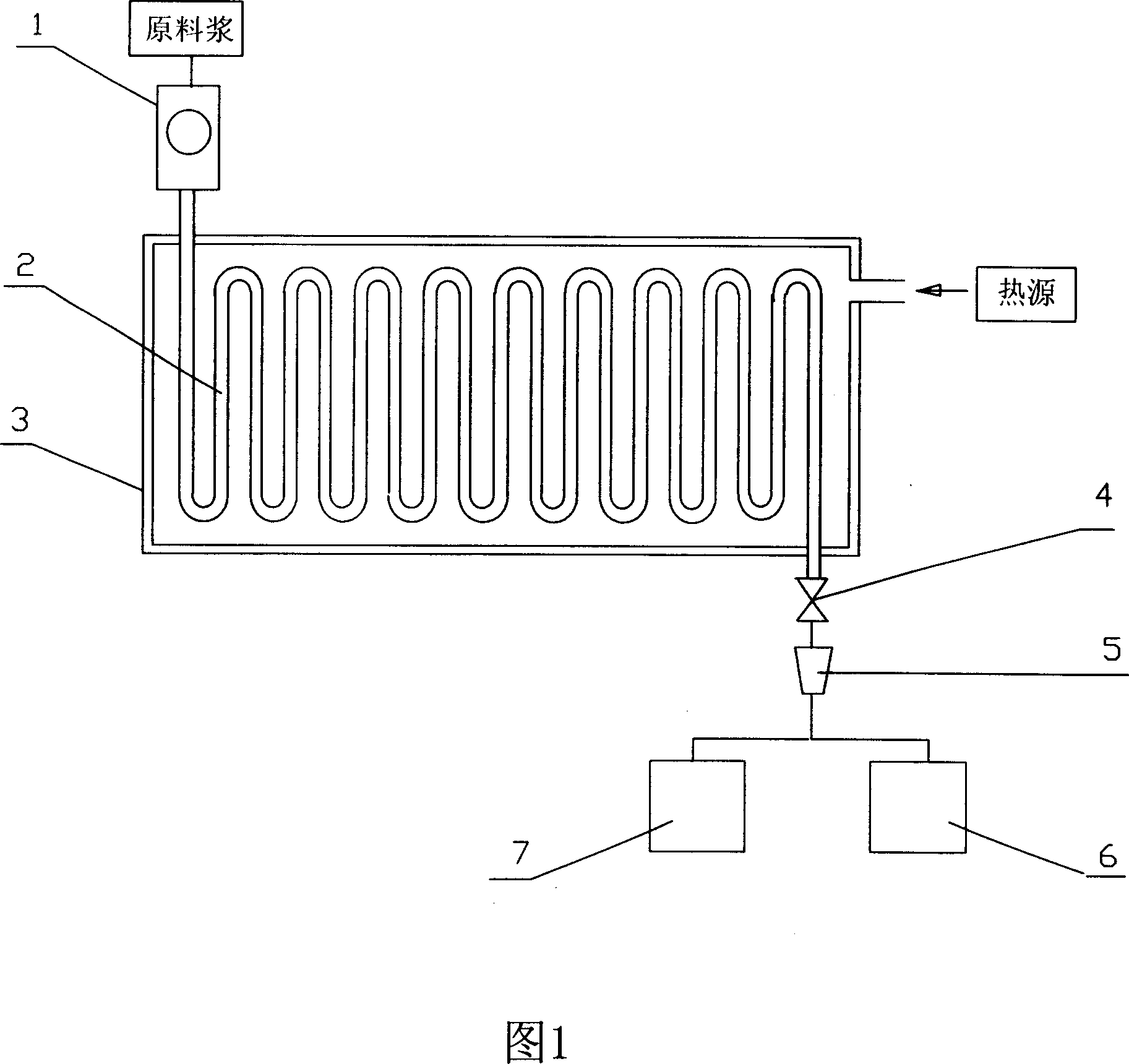

[0018] A continuous production method of α-type hemihydrate gypsum, using dihydrate gypsum slurry as raw material, continuously pumping the dihydrate gypsum slurry into a reaction tube arranged in a heating box with a high-pressure pump, and the raw material slurry flows in the tube during the process When the temperature and pressure reach a certain value and keep it for a certain period of time, the dihydrate gypsum removes a semi-crystalline water to generate α-type hemihydrate gypsum, and the slurry containing α-type hemihydrate gypsum is sprayed into the drying separation tower through the nozzle, thereby obtaining drying. α-type hemihydrate gypsum powder; or spray into the gypsum stirring and forming device to make gypsum products.

[0019] When the slurry containing dihydrate gypsum is continuously pumped in by one end of the high-pressure pump, the other end discharges the slurry containing α-type hemihydrate gypsum 3 after dehydration reaction; that is to say, the leng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com