Ready-to-eat special flavor fish product subjected to cold smoking, and production process thereof

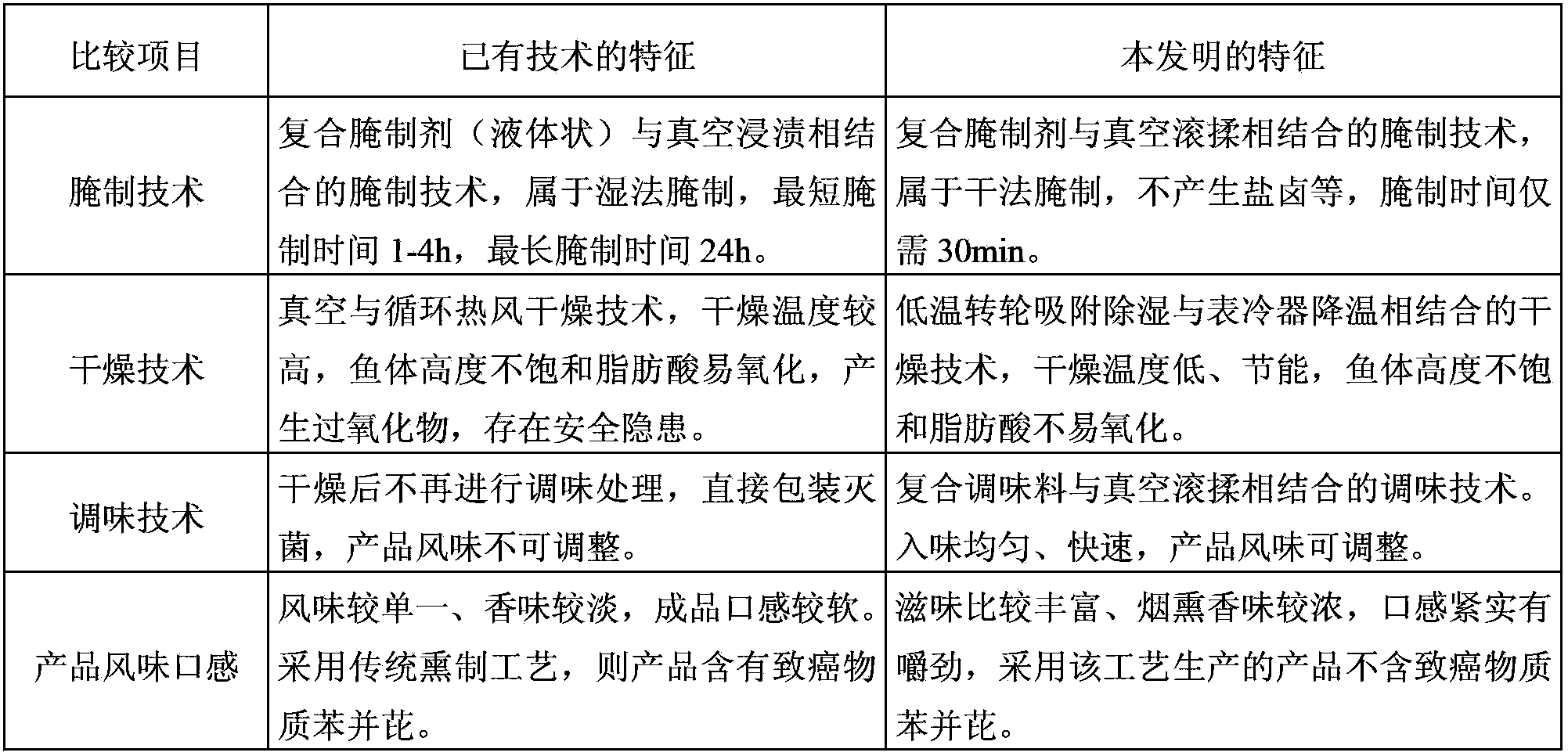

A technology for flavored fish and cold smoking, applied in food preparation, food science, application and other directions, can solve the problems of unfavorable industrial production, a large amount of salt and brine, and high hot air drying temperature, so as to improve the quality of dried products, solve uneven seasoning, improve The effect of penetration rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

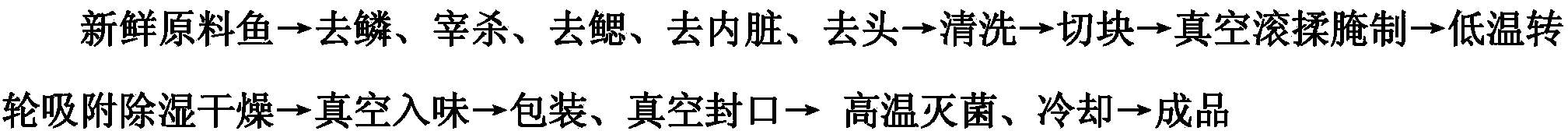

Method used

Image

Examples

Embodiment 1

[0067] Embodiment 1: Production of semi-finished products of cold-smoked ready-to-eat flavor fish products

[0068] (1) Buy fresh silver carp, grass carp, or carp with a weight of about 1-2kg / tail from the market, remove scales, slaughter, gills, viscera, head, wash, drain the surface water, and then use cut Block machine cut into (3 ± 0.2) cm × (2 ± 0.2) cm squares.

[0069] (2) Put 100kg of pretreated fish pieces into a vacuum tumbler (Shenyang Haiheng Food Machinery Factory, model ZKGRJ-20), add 1.5kg of pepper salt (stir-fry the salt in the pot to 200°C first, Then add 5% of the amount of salt pepper, mix well, remove from the fire, continue to stir fry until the temperature drops below 50°C, set aside), 0.5kg white sugar, 1.0kg ginger (pieces), 0.5kg licorice (powder) and 1.0kg tobacco Smoked liquid (commodity raw material of smoked liquid purchased from Hawthorn Nut Smoked Flavor No. 1 produced by Jinan Hualu Food Co., Ltd.) and sealed, and then vacuumed with a vacuum p...

Embodiment 2

[0071] Embodiment 2: the production of cold-smoked ready-to-eat flavor fish product finished product

[0072] (1) Put 45kg of dried fish pieces with smoky flavor prepared in Example 1 into a vacuum flavoring machine (Shenyang Haiheng Food Machinery Factory, model ZKGRJ-20), and then add 1.0kg of salt, 1.5kg of White sugar, 5.0kg red oil, 1.0kg monosodium glutamate, 2.5kg sesame seeds, 0.5kg dried chili flakes and 0.5kg perilla leaves form a compound seasoning and seal it, then use a vacuum pump to evacuate to a vacuum degree of 0.08-0.095MPa, Under the conditions of 10-15°C and a rotating speed of 5-12r / min, the vacuum flavoring treatment is carried out for 10-20min.

[0073] (2) Slowly open the intake valve to eliminate the vacuum of the vacuum flavoring machine, and then take out the seasoned fish pieces. Fill the fish pieces into aluminum foil composite retort bags and vacuum seal.

[0074] (3) Put the vacuum-packed fish pieces in an autoclave, sterilize them under high-p...

Embodiment 3

[0075] Embodiment 3: the production of cold-smoked ready-to-eat flavor fish products

[0076] (1) Buy fresh silver carp, grass carp, or carp with a weight of about 1-2kg / tail from the market, remove scales, slaughter, gills, viscera, head, wash, drain the surface water, and then use cut Block machine cut into (3 ± 0.2) cm × (2 ± 0.2) cm squares.

[0077] (2) Put 100kg of pretreated fish pieces into a vacuum tumbler (Shenyang Haiheng Food Machinery Factory, model ZKGRJ-20), add 2.0kg of pepper salt (stir fry the salt in the pot to 200°C first, Then add 5% of the amount of salt pepper, mix well, remove from the fire, continue to stir fry until the temperature drops below 50°C, set aside), 1.0kg white sugar, 1.5kg ginger (pieces), 0.1kg licorice (powder) and 2.0kg tobacco Smoked liquid (commodity raw material of smoked liquid purchased from Hawthorn Nut Smoked Flavor No. 1 produced by Jinan Hualu Food Co., Ltd.) and sealed, and then vacuumed with a vacuum pump to a vacuum degree...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com