Environmental-friendly active dye digital printing pretreatment prime pulp and preparation method thereof

A reactive dye, digital printing technology, applied in the field of printing and dyeing, can solve the problems of large environmental pollution and poor universality of the primer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

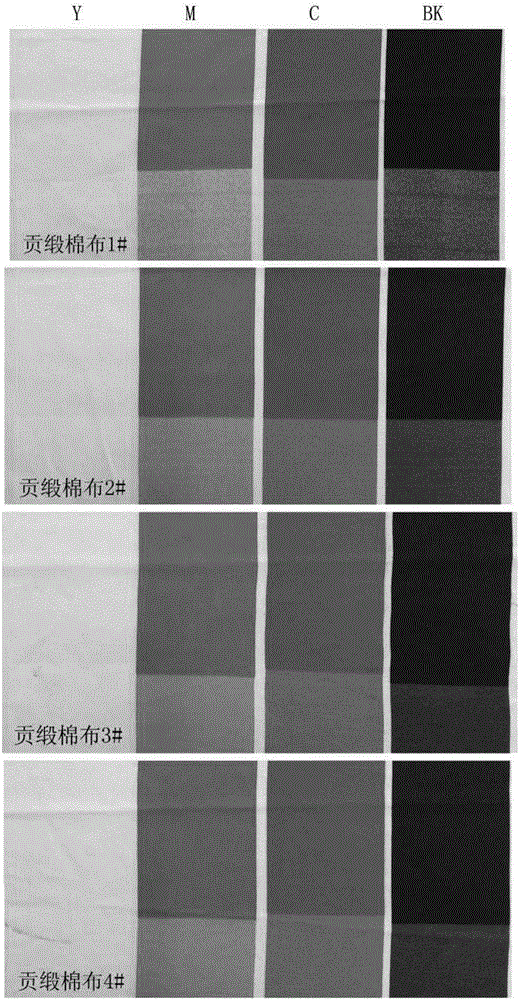

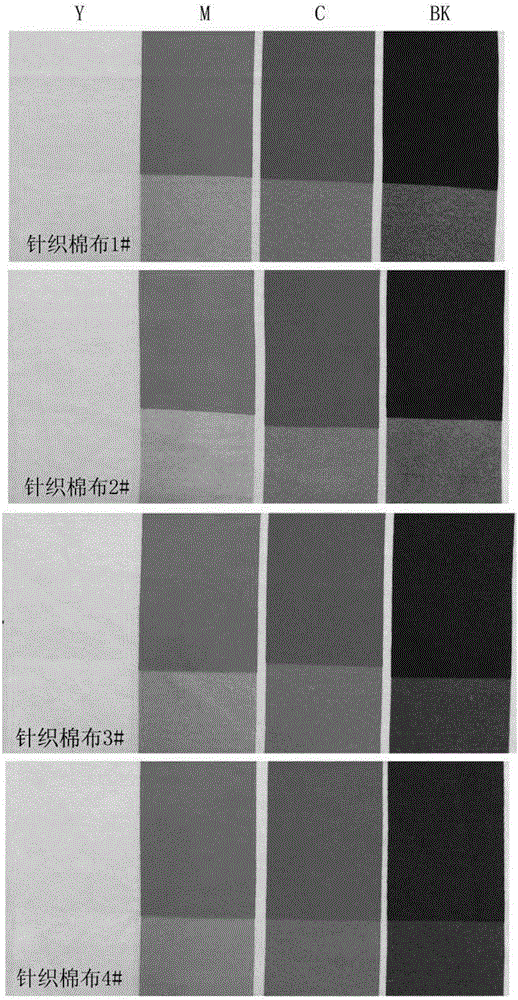

Examples

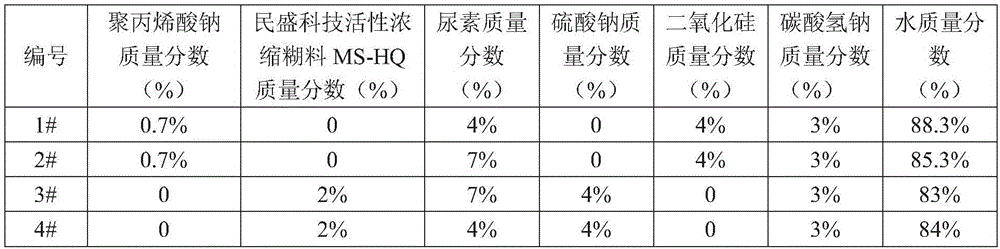

Embodiment 1

[0034] Take by weighing the water of 86 mass parts, take by weighing the thickening agent of 0.7 mass parts and add in water and stir and dissolve, then weigh the cellulose fiber bulking agent of 5 mass parts, the hygroscopic agent of 0.5 mass parts, the alkali agent of 3 mass parts, the alkali agent of 4 mass parts The dyeing accelerator of mass parts, the preservative of 0.3 mass parts, the anti-reducing agent of inkjet printing of 0.5 mass parts are added into water, wherein, the thickener is paste DGT-7 and sodium polyacrylate, and the dyeing accelerator is silicon dioxide, the cellulose fiber bulking agent is urea, the hygroscopic agent is glycerin, the alkali agent is potassium carbonate, and the preservative is 1,2-benzisothiazolin-3-one, so The anti-reducing agent is anti-staining salt S, which is fully dissolved to obtain an environment-friendly reactive dye digital printing pretreatment primer. The commonly used dyeing accelerator is sodium chloride, and water-insolu...

Embodiment 2

[0036] Take by weighing the water of 86.2 mass parts, take by weighing the thickening agent of 0.5 mass parts and add in water and stir and dissolve, then weigh the cellulose fiber bulking agent of 5 mass parts, the hygroscopic agent of 0.5 mass parts, the alkali agent of 3 mass parts, the alkali agent of 4 mass parts Mass parts of dye accelerator, 0.3 mass parts of preservative, 0.5 mass parts of inkjet printing anti-reducing agent are added to water, wherein the thickener is a mixture of sodium polyacrylate and active concentrated paste MS-HQ of Minsheng Technology , the dyeing accelerator is silicon dioxide, the cellulose fiber bulking agent is liquid ammonia, the hygroscopic agent is a mixture of glycerin and Xiaofan 465, the alkali agent is potassium carbonate, and the preservative is 1,2 - benzisothiazolin-3-one, the anti-reducing agent is anti-dyeing salt S, which is fully dissolved to obtain an environment-friendly reactive dye digital printing pretreatment primer.

Embodiment 3

[0038] Weigh 87.3 parts by mass of water, weigh 0.7 parts by mass of thickener and add to water to stir and dissolve, then weigh 5 parts by mass of cellulose fiber bulking agent, 3 parts by mass of alkali agent, 4 parts by mass of dye accelerator and add In water, wherein, the thickener is sodium polyacrylate, the dye accelerator is sodium sulfate, the cellulose fiber bulking agent is urea, and the alkali agent is a mixture of sodium carbonate and sodium hydroxide, fully dissolved to obtain Environmentally friendly reactive dye digital printing pretreatment primer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com