A kind of active digital printing base paste and preparation method thereof

A technology of digital printing and primer, applied in dyeing, textile and papermaking, etc., can solve the problems of difficult cleaning of printing paste, high price of synthetic paste, poor coloring ability, etc., to improve K/S value and seepage rate, improve color fastness, high paste rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

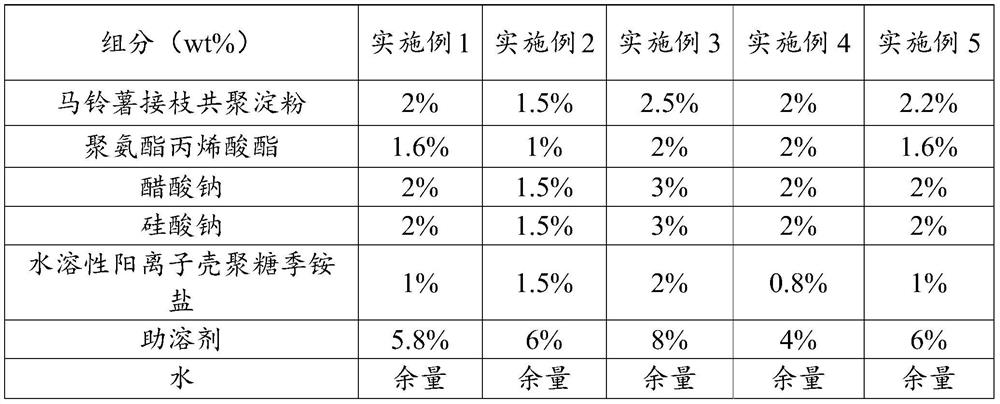

[0025] The weight percent composition formula of the active digital printing bottom slurry described in embodiment 1~5 is as shown in table 1;

[0026] The preparation method of the active digital printing bottom slurry described in embodiment 1~5, comprises the following steps:

[0027] (1) adding potato graft copolymerized starch and polyurethane acrylate into deionized water according to the weight ratio, mixing evenly and stirring, and standing for 8 to 18 hours to obtain the mixed raw paste;

[0028] (2) Add glycerol, triethylene glycol and sodium glycolate to the water in step (1), and stir evenly;

[0029] (3) Add sodium acetate, sodium silicate, and water-soluble cationic chitosan quaternary ammonium salt into step 2) and mix and stir evenly.

[0030] The weight ratio of glycerol, triethylene glycol and sodium glycolate described in Examples 1 to 5 is: glycerol: triethylene glycol: sodium glycolate=1:1:1.

[0031] Table 1

[0032]

Embodiment 6~16 and comparative example 1~8

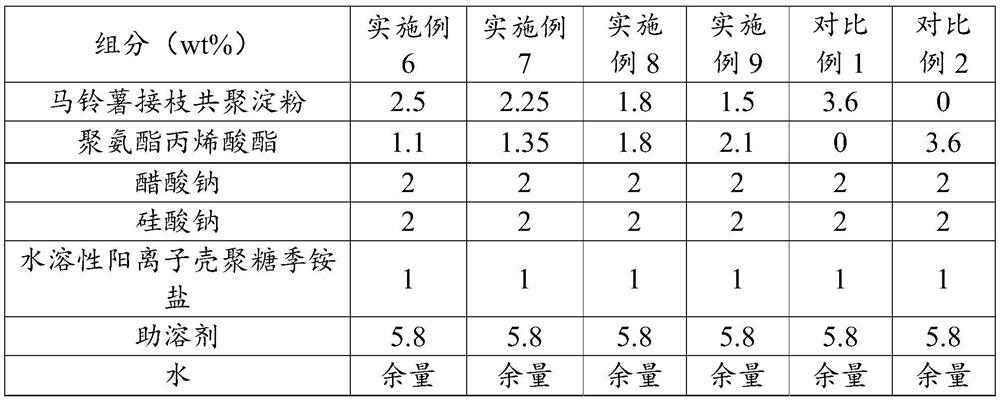

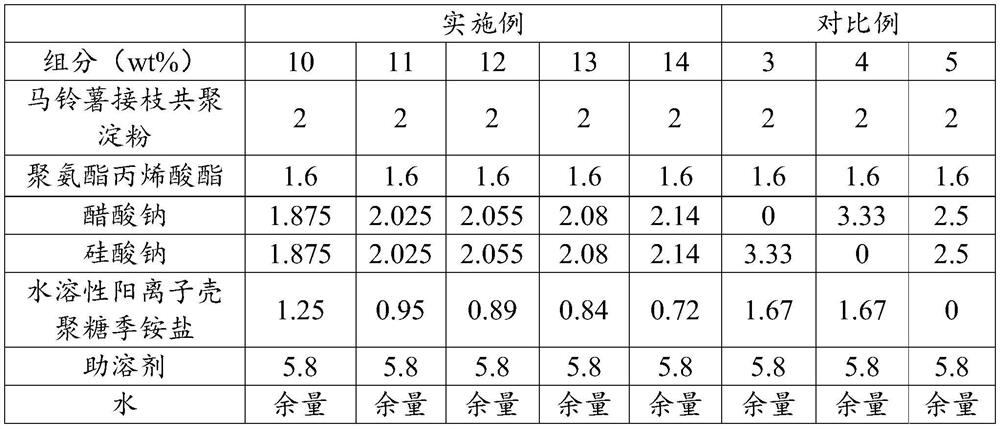

[0034] The weight percent formula of the active digital printing base slurry described in Examples 6~9 and Comparative Examples 1~2 is as shown in Table 2; Embodiment 10~14 and the active digital printing base slurry described in Comparative Examples 3~5 The weight percentage composition formula of embodiment 15~16 and the active digital printing base slurry described in comparative example 6~7 are as shown in table 4, and embodiment 6~16 and contrast example 6~7 are as shown in table 3. The preparation method of the reactive digital printing base slurry of ratio 1-7 is the same as that of Examples 1-5.

[0035] Table 2

[0036]

[0037] table 3

[0038]

[0039] Table 4

[0040]

[0041]

Embodiment 17

[0043] Taking cotton knitted fabrics as an example, the application method of the active digital printing base paste in the fabrics of Examples 1-16 and Comparative Examples 1-7 is adopted. The method comprises the following steps: using the above-mentioned active printing base paste to process the fabric Printing, baking, steaming, washing, soaping and drying;

[0044] Wherein, the temperature of baking is 70-80°C, and the temperature of steaming is 105-115°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com