Phosphate tapioca starch and preparation method thereof, composite dispersion printing paste for polyester silk chiffon fabric and preparation method thereof

A technology of cassava starch and printing paste, which is applied in dyeing, textiles and papermaking, can solve the problems of reducing application costs, and achieve the effects of reducing production costs, simple raw material acquisition, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

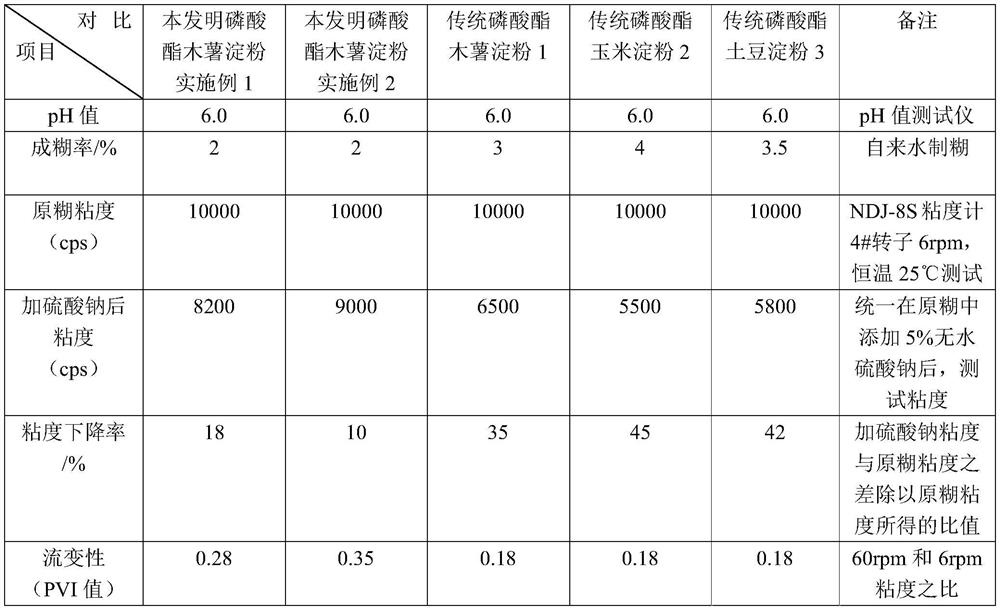

Examples

Embodiment 1

[0048] Methods of phosphate cafeterian starch preparation methods of this embodiment are as follows:

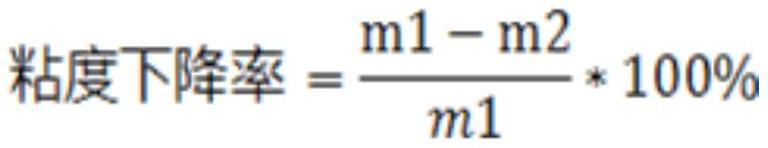

[0049] Called 500kg of cassava raw starch to emulsified ions, and then add 1000kg to remove ionic water. The obtained starch emulsion was pumped into the reactor, and the reactor dispersing machine's rotation was controlled at 50-80 rpm / min continuously, adding 15kg of sodium sulfate, adding a 32 % concentration of liquid alkali 30kg to adjust the pH8-11, and the temperature was increased to 50 ° C. Slowly add 5kg oxide propylene cross -linked reactions and continue to react for 1.5 hours. After the reaction is completed, the cross -linked starch milk is required, and the pH value of the 25kg hydrochloric acid solution is used to 6. It is said that 5Kg of hyperlolate polyoxyethylene ether is used to add the cross -linked starch lactifer solution for esterization before treatment. The temperature continues to keep at 50 ° C, so that the water is fully exposed to starch particles, ...

Embodiment 2

[0052] Called 500kg of cassava raw starch to emulsified ions, and then add 1000kg to remove ionic water. The obtained starch emulsion was pumped into the reactor, and the reactor dispersing machine's rotation was controlled at 50-80 rpm / min continuously, adding 15kg of sodium sulfate, adding a 32 % concentration of liquid alkali 30kg to adjust the pH8-11, and the temperature was increased to 50 ° C. Slowly add 8kg ethylene cross -linked reactions and continue to react for 1.5 hours. After the reaction is completed, the cross -linked starch milk is required, and the pH value of the 25kg hydrochloric acid solution is used to 6. It is said that 5Kg of hyperlolate polyoxyethylene ether is used to add the cross -linked starch lactifer solution for esterization before treatment. The temperature continues to keep at 50 ° C, so that the water is fully exposed to starch particles, and the ester pharmaceutical agent and starch are fully exposed to reactions. Add 15kg of sodium dihydrogen ph...

Embodiment 3

[0063] The preparation method of composite decentralized printed paste for polyester chiffon fabrics for this embodiment is as follows:

[0064] 1. Complex and mixing: 50 copies of the phosphate cafeteria starch material prepared by the Illegal Example 2; 30 copies of hydroxyl -petuga bean gum, 10 sodium -based pussy soil; 4 copies of hydroxyeylcellin; Huangyuan collagen 2 Severe; 1 citric acid; put the above powder raw materials into a mixed kettle and stir at low speed at room temperature. After stirring the above powder for 30 minutes, use the spraying equipment to spray the three parts of the water -based polyurethane deeper (thickened) into the powder system, continue to stir for 10 minutes, and add 0.1 BIT preservatives to continue stirring for 10 minutes until the stirring is completely mixed completely until the stirring is completely stirred completely Uniform.

[0065] 2. Dry drying: Enter the drying box of the mixed material through the pipeline transmission system. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com