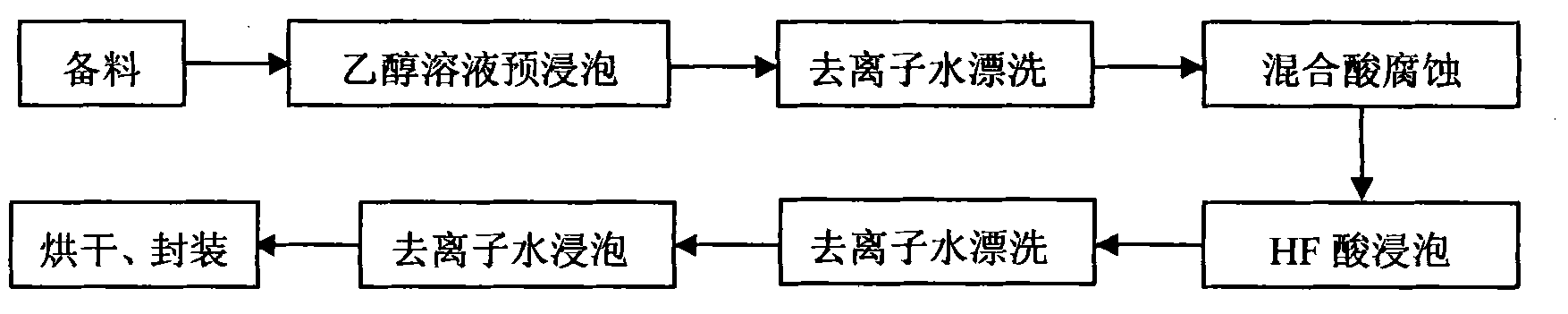

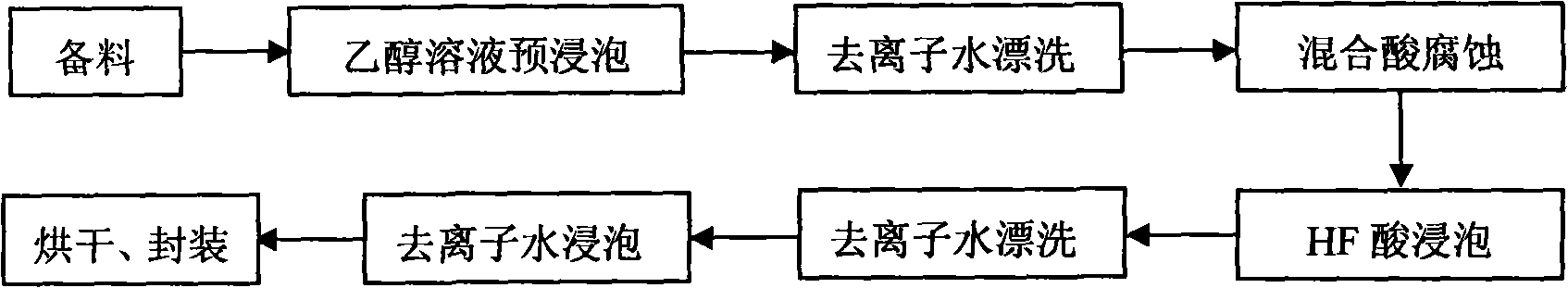

Cleaning method of policrystalline silicon raw material

A technology of raw materials and rinsing time, applied in chemical instruments and methods, crystal growth, post-processing details, etc., can solve the problems of attached impurity oxide film, less impurity content, uneven corrosion, etc., and achieve easy control and operation, low impurity content The effect of less and less acid consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Specific examples are given below to further illustrate how the present invention is realized.

[0014] 1. Material preparation: The reaction rate of silicon polycrystalline raw material in mixed acid solution is related to the specific surface area of silicon polycrystalline raw material. The larger the specific surface area, the faster the reaction rate of silicon polycrystalline raw material and mixed acid solution. Therefore, the raw materials should be reasonably classified according to their size before cleaning, and each type of raw material should be cleaned separately to ensure that the corrosion time of the raw materials is easy to control during the cleaning and corrosion process and the surface corrosion is uniform. In actual operation, silicon polycrystalline raw materials are divided into four categories according to size: the first category raw material size ≤ 30mm; the second category raw material size between 30mm ~ 60mm; the third category raw materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com