Production technique of high-accuracy cold-rolling carbon-steel steel belt for electronic industry

A production technology and technology in the electronics industry, applied in metal material coating technology, metal rolling, manufacturing tools, etc., can solve the problems of unstable mechanical properties, large fluctuations in thickness tolerance of cold-rolled steel strips, and high costs, and achieve surface color and luster. Uniformity, small thickness tolerance fluctuations, and improved product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

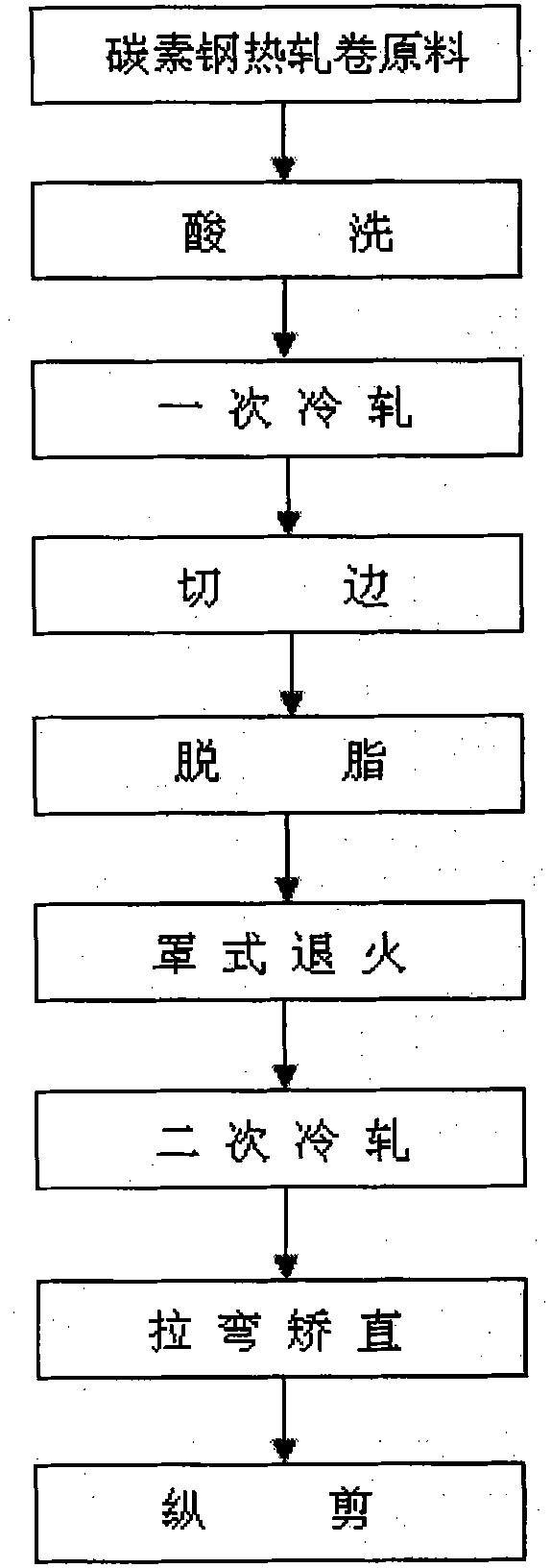

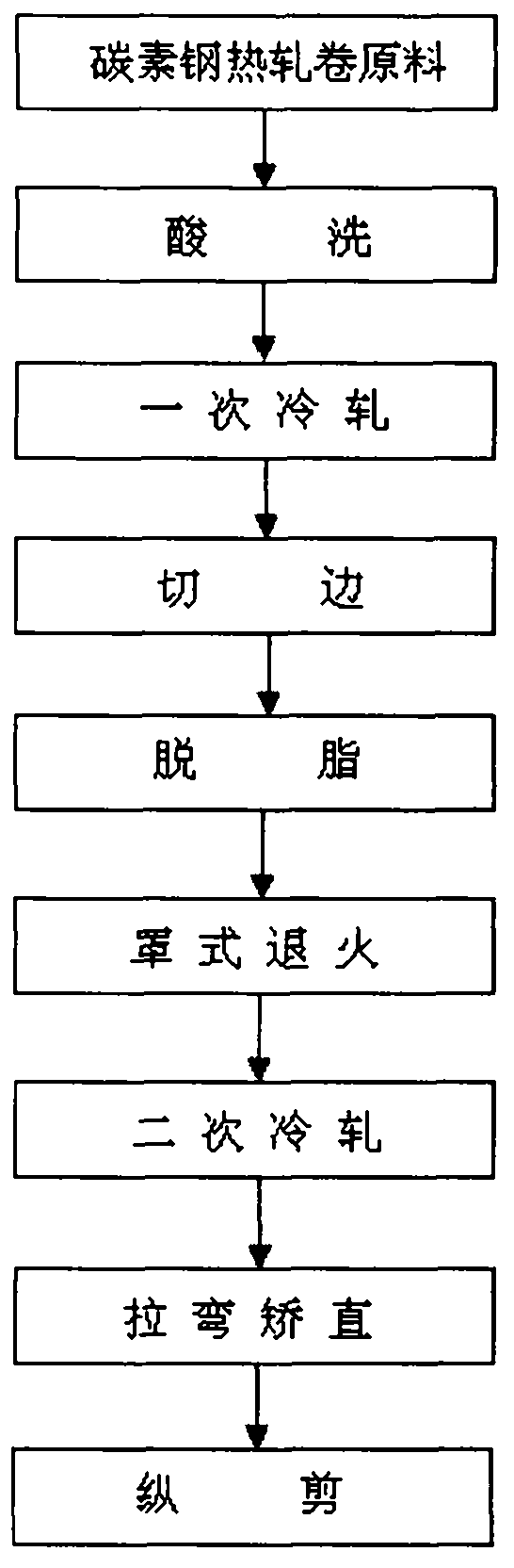

Image

Examples

Embodiment 1

[0022] The process of this embodiment selects the hot-rolled steel coil of SPHC as the raw material, the carbon content is 0.04%, the thickness is 2.75mm, the width is 415mm, the thickness of the finished steel strip is 0.20mm, the state is 1 / 2 hard, and the hardness is 140 ~170HV 0.3 .

[0023] The present invention adopts following processing steps:

[0024] a. The hot-rolled steel coil with a thickness of 2.75mm and a carbon content of 0.04% is uncoiled on the pickling unit, and the uncoiled steel strip is pickled with hydrochloric acid in the three-stage pickling tank of the pickling unit. In the first section of pickling tank, hydrochloric acid and water are mixed to form a hydrochloric acid pickling solution with a weight concentration of 7%. The temperature of the hydrochloric acid pickling solution in the first section of pickling tank is 77°C. The hydrochloric acid and water are prepared into a hydrochloric acid pickling solution with a weight concentration of 9%. T...

Embodiment 2

[0044] The process of this embodiment selects the hot-rolled steel coil of SPHC as the raw material, the carbon content is 0.05%, the thickness is 3.0mm, the width is 415mm, the thickness of the finished steel strip is 0.25mm, the state is 1 / 2 hard, and the hardness is 140 ~170HV 0.3 .

[0045] The present invention adopts following processing steps:

[0046] a. The hot-rolled steel coil with a thickness of 3.0mm and a carbon content of 0.05% is uncoiled on the pickling unit, and the uncoiled steel strip is pickled with hydrochloric acid in the three-stage pickling tank of the pickling unit. In the first section of pickling tank, hydrochloric acid and water are mixed to form a hydrochloric acid pickling solution with a weight concentration of 5%. The temperature of the hydrochloric acid pickling solution in the first section of pickling tank is 80°C. The hydrochloric acid and water are prepared into a hydrochloric acid pickling solution with a weight concentration of 8%. The t...

Embodiment 3

[0066] The process of this embodiment selects the hot-rolled steel coil of SPHC as the raw material, the carbon content is 0.02%, the thickness is 3.0mm, the width is 490mm, the thickness of the finished steel strip is 0.40mm, the state is 1 / 2 hard, and the hardness is 140 ~170HV 0.3 .

[0067] The present invention adopts following processing steps:

[0068] a. The hot-rolled steel coil with a thickness of 3.0mm and a carbon content of 0.02% is uncoiled on the pickling unit, and the uncoiled steel strip is pickled with hydrochloric acid in the three-stage pickling tank of the pickling unit. In the first section of pickling tank, hydrochloric acid and water are mixed to form a hydrochloric acid pickling solution with a weight concentration of 10%. The temperature of the hydrochloric acid pickling solution in the first section of pickling tank is 75°C. The hydrochloric acid and water are prepared into a hydrochloric acid pickling solution with a weight concentration of 10%. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Unevenness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com