Trench structure for power device and manufacturing method thereof

A technology of power devices and manufacturing methods, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve problems such as the influence of changes in silicon nitride films, deterioration of silicon oxide films, and changes in device performance, so as to meet the needs of high-quality, silicon Elimination of interface defects and good electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

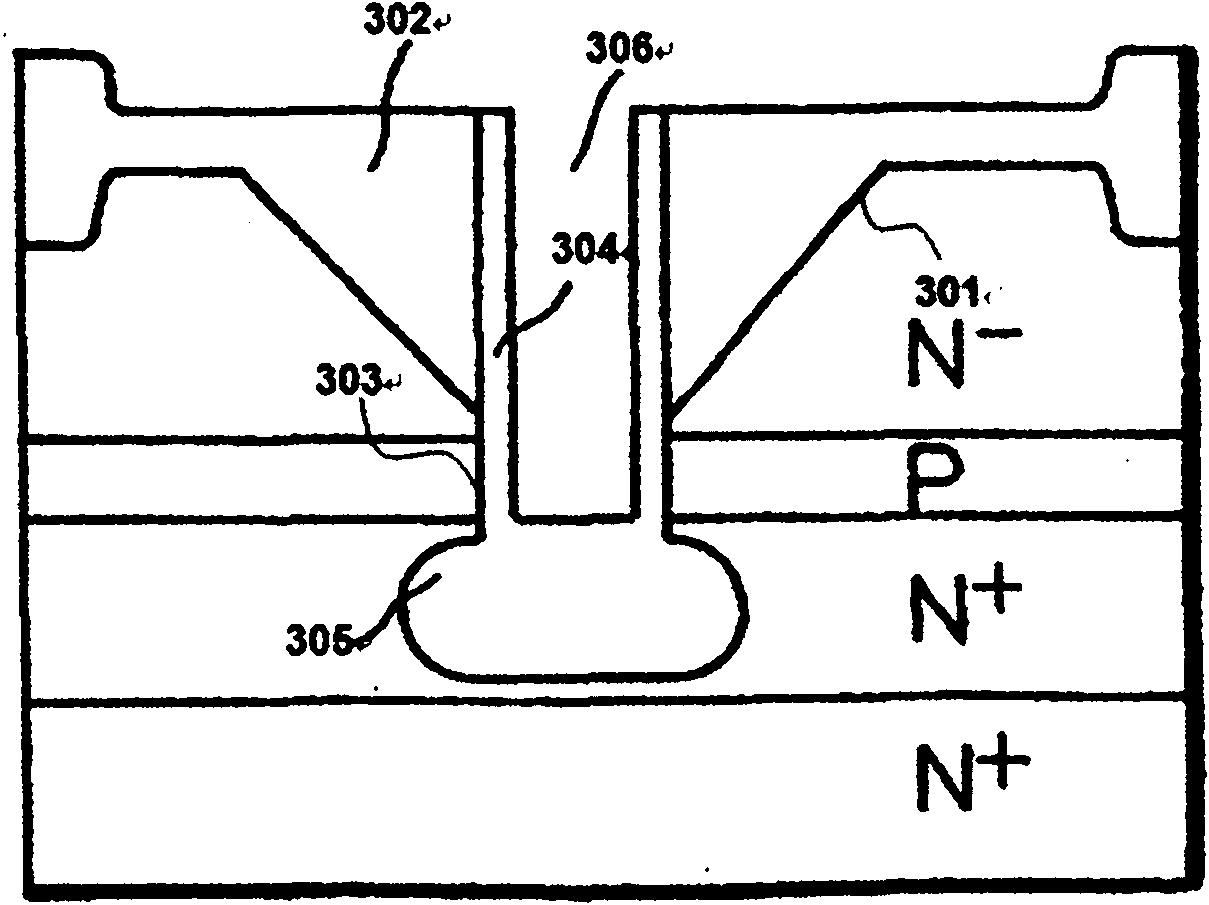

[0033] refer to Figure 5 The trench structure used for power devices is a trench (width: micron or submicron, Depth: 1-10 microns) 501 has a layer of selectively grown silicon oxide film 502 with a thick bottom and a high-quality silicon oxide film 503 with thin side walls, and the gap-free filling on the silicon oxide film 503 in the trench 501 has good electrical conductivity Doped polysilicon film 504, after the polysilicon film on the surface of the silicon wafer at the trench is removed, the surface of the silicon wafer forms a stepless or small step shape 505 within 1000 Angstroms. When removing the polysilicon film outside the trench, the silicon A layer of silicon oxide film 506 is left on the wafer surface to ensure that the silicon surface is not damaged.

[0034] The trench structure manufacturing method for power devices disclosed in the presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com