Shooting lens and module thereof, and terminal

A camera lens and lens technology, applied in optical components, optics, instruments, etc., can solve the problem that the length of the system cannot be further shortened, and achieve the effects of improving imaging quality, correcting off-axis aberration, and reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

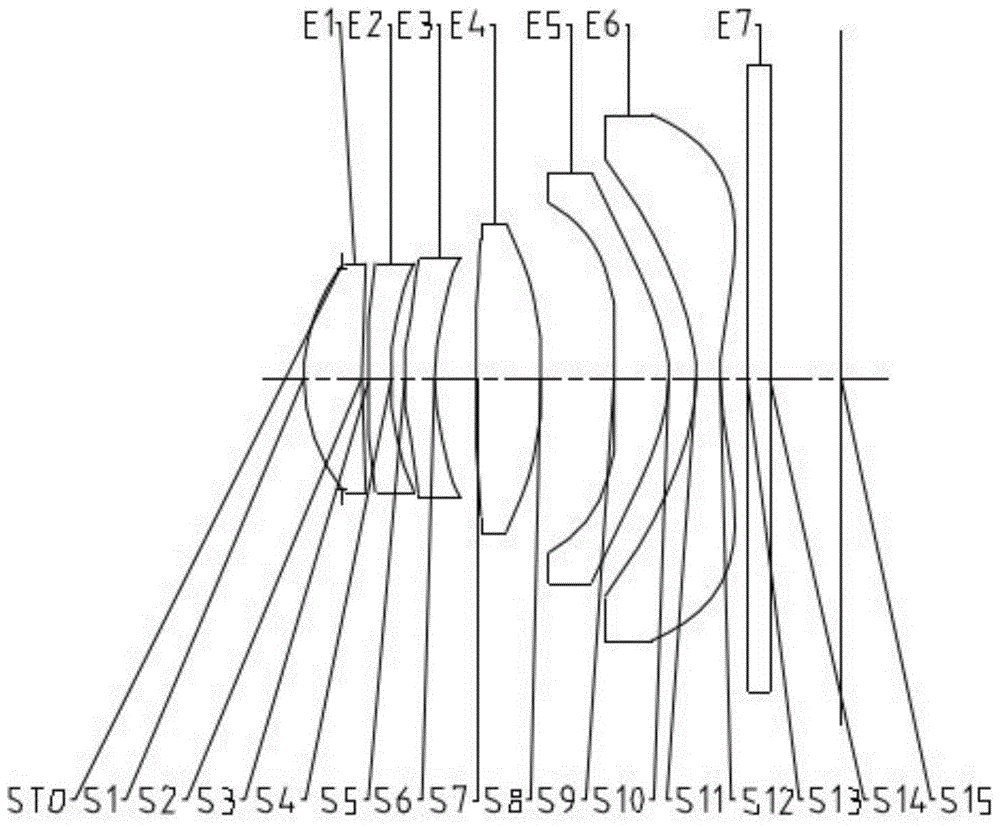

Embodiment 1

[0073] The parameters of the camera lens in Example 1 are as follows: TTL=5.003; f1=4.373; f2=-10.633; f3=-37.031; f4=6.865; f5=2.536; f6=-1.726; f=4.251;

[0074] f1.2.3 / Dr1r6=5.930

[0075] T3.5 / TTL=0.334

[0076] SAG61 / CT6=-3.784

[0077] System parameters: 1 / 3" photosensitive device aperture value 2.05

[0078] Table 1

[0079] surface type

radius of curvature

thickness

Material

Effective caliber

Conic coefficient

sphere

infinity

infinity

sphere

infinity

-0.3460

2.0736

Aspherical

1.7080

0.5408

1.544 / 56.1

2.1336

-0.0731

Aspherical

Aspherical

5.3321

6.2657

0.0614

0.2130

1

1.635 / 23.7

2.1415

2.1478

-54.2177

-49.7859

Aspherical

3.2195

0.1263

8

2.1411

0.3020

Aspherical

2.3343

0.2758

1.635 / 23.7

2.1709

-6.6575

Aspherical

2.0270

0.3873

8...

Embodiment 2

[0085] Each parameter of camera lens in embodiment 2 is as follows:

[0086] TTL=4.022; f1=2.974; f2=-5.412; f3=-26.811; f4=5.851; f5=2.160; f6=-1.486; f=3.346;

[0087] f1.2.3 / Dr1r6=5.650

[0088] T3.5 / TTL=0.281

[0089] SAG61 / CT6=-3.154

[0090] System parameters: 1 / 4" photosensitive device aperture value 2.05

[0091] table 3

[0092] surface type

radius of curvature

thickness

Material

Effective caliber

Conic coefficient

sphere

infinity

infinity

sphere

infinity

-0.2799

1.6320

Aspherical

1.3344

0.4935

1.544 / 56.11

1.6873

-0.2928

Aspherical

6.5034

0.0368

1.6719

-6.7573

Aspherical

9.3518

0.1996

1.635 / 23.78

1.6659

21.8315

Aspherical

2.5075

0.1130

1.6719

3.5516

Aspherical

1.6622

0.2030

1.635 / 23.78

1.6891

-5.5824

[0093] Asph...

Embodiment 3

[0099] The parameters of the camera lens in Example 3 are as follows: TTL=3.993; f1=3.785; f2=-6.325; f3=-20.054; f4=3.693; f5=2.268; f6=-1.482; f=3.219;

[0100] f1.2.3 / Dr1r6=9.487

[0101] T3.5 / TTL=0.309

[0102] SAG61 / CT6=-2.777

[0103] System parameters: 1 / 4" photosensitive device aperture value 2.05

[0104] table 5

[0105] surface type

radius of curvature

thickness

Material

Effective caliber

Conic coefficient

sphere

infinity

infinity

sphere

infinity

-0.2256

1.5701

Aspherical

1.4780

0.4185

1.544 / 56.11

1.6183

-0.0943

Aspherical

4.6718

0.0921

1.6336

-24.6257

Aspherical

7.4401

0.2078

1.635 / 23.78

1.6429

-99.2317

Aspherical

2.5937

0.0933

1.7301

-1.8098

Aspherical

1.6733

0.2260

1.635 / 23.78

1.7480

-5.8101

Aspherical

1.4024

0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com