Preparation method of multicomponent large-size rare earth boride LaxCe1-xB6 monocrystalline block cathode material

A rare earth boride, single crystal material technology, applied in the growth of polycrystalline materials, chemical instruments and methods, single crystal growth and other directions, can solve the problems of small size and poor quality, and achieve large size, high quality and high purity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] (1) LaB 6 with CeB 6 After the powders were mechanically mixed according to the stoichiometric ratio of 6:4, they were loaded into a graphite mold with an inner diameter of Ф15 mm and a height of 140 mm for vacuum discharge plasma sintering (SPS). The sintering parameters are as follows, sintering temperature: 1150° C., sintering pressure: 0 MPa, holding time: 5 minutes, heating rate: 110° C. / min.

[0016] (2) Cut the sintered polycrystalline rod into seed crystals and feed rods with a diameter of Φ7mm, and carry out zone melting in an optical zone melting furnace. In order to effectively suppress the volatilization and oxidation of La and Ce elements, a high-purity flowing argon gas was introduced into the quartz tube with a gas flow rate of 1 L / min and a gas pressure of 0.5 MPa. In order to make the melting zone more uniform, the seed crystal and the material rod are rotated in reverse, the rotation speed is 30rpm, and the growth rate is 7mm / h.

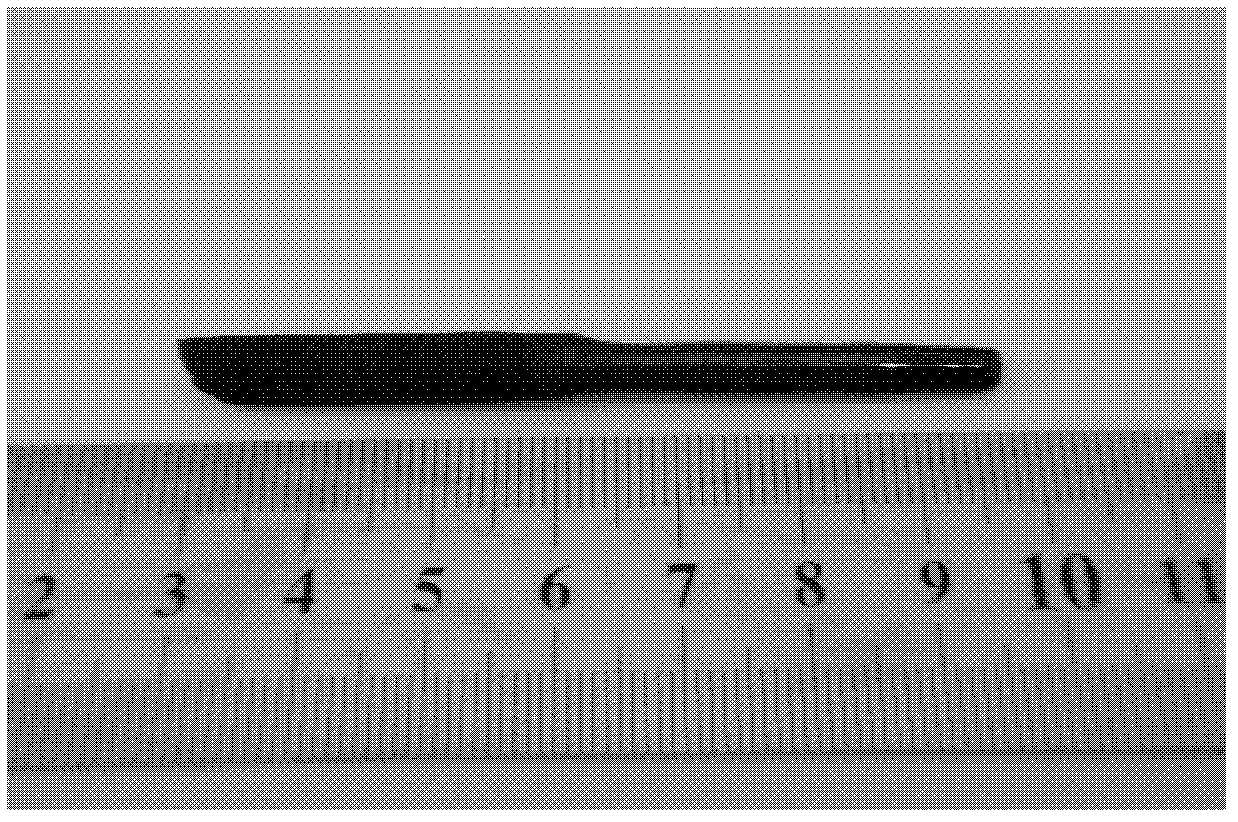

[0017] From figur...

Embodiment 2

[0019] (1) LaB 6 with CeB 6 After the powders were mixed mechanically according to the stoichiometric ratio of 4:6, they were loaded into a graphite mold with an inner diameter of Ф15 mm and a height of 140 mm for vacuum discharge plasma sintering (SPS). The sintering parameters are as follows, sintering temperature: 1200°C, sintering pressure: 10MPa, holding time: 5min, heating rate: 110°C / min.

[0020] (2) Cut the sintered polycrystalline rod into seed crystals and feed rods with a diameter of Φ7mm, and carry out zone melting in an optical zone melting furnace. In order to effectively suppress the volatilization and oxidation of La and Ce elements, a high-purity flowing argon gas was introduced into the quartz tube with a gas flow rate of 2 L / min and a gas pressure of 0.6 MPa. In order to make the melting zone more uniform, the seed crystal and the material rod are rotated in reverse, the rotation speed is 40rpm, and the growth rate is 8mm / h.

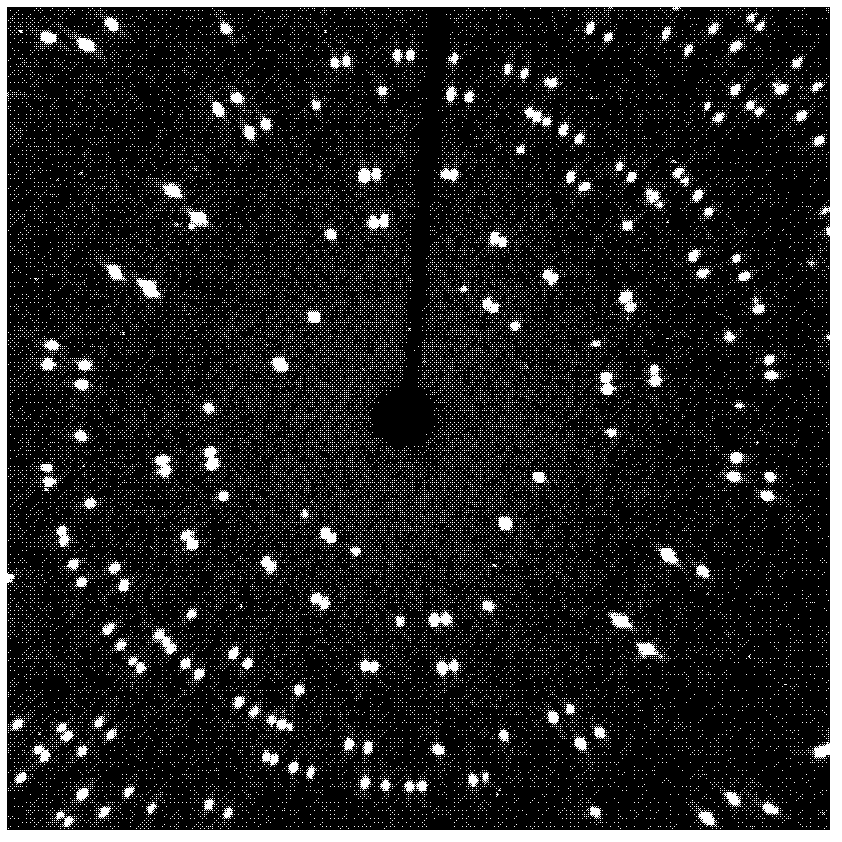

[0021] 360-degree Phi scan ...

Embodiment 3

[0023] (1) The LaB6 and CeB6 powders were put into a graphite mold with an inner diameter of Ф15 mm and a height of 140 mm according to a chemical ratio of 2:8, and vacuum discharge plasma sintering (SPS) was carried out. The sintering parameters are as follows, sintering temperature: 1200°C, sintering pressure: 20MPa, holding time: 5min, heating rate: 120°C / min.

[0024] (2) Cut the sintered polycrystalline rod into seed crystals and feed rods with a diameter of Φ7mm, and carry out zone melting in an optical zone melting furnace. In order to effectively suppress the volatilization and oxidation of La and Ce elements, a high-purity flowing argon gas was introduced into the quartz tube with a gas flow rate of 2 L / min and a gas pressure of 0.7 MPa. In order to make the melting zone more uniform, the seed crystal and the material rod are rotated in reverse, the rotation speed is 40rpm, and the growth rate is 10mm / h.

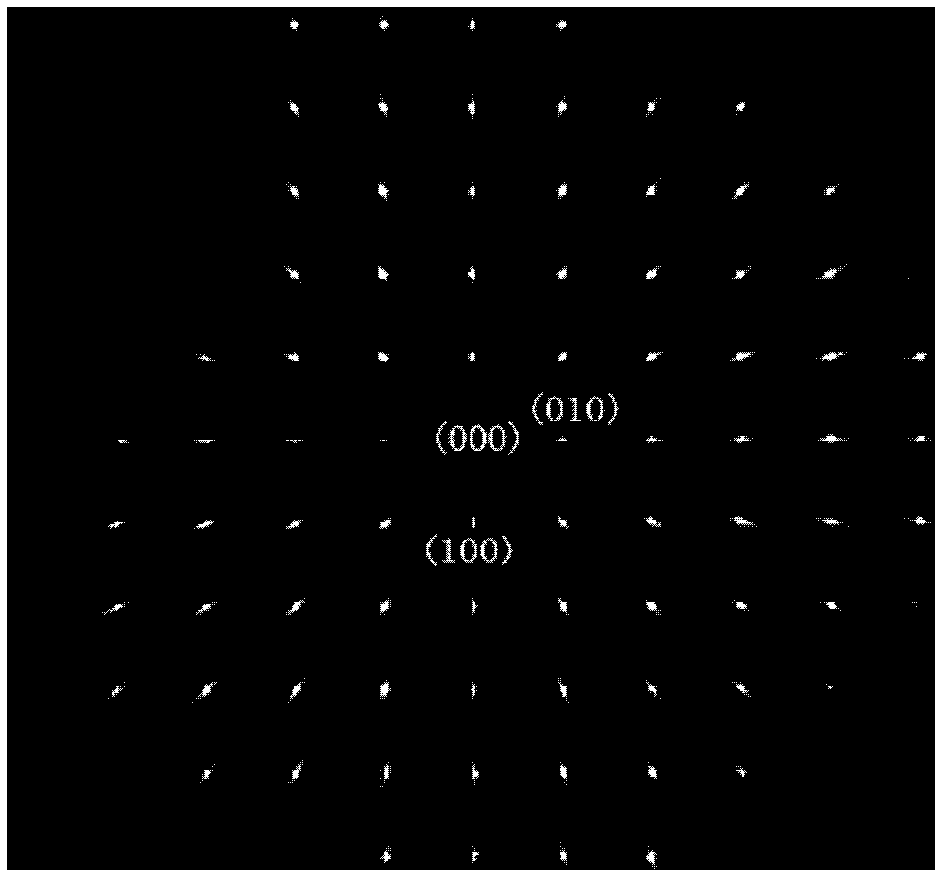

[0025] 360-degree Phi scan fast scan and slow scan along the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com