Making method for low-temperature multi-crystal silicon film

A technology of low-temperature polysilicon and a manufacturing method, which is applied in the manufacture of semiconductor/solid-state devices, electrical components, circuits, etc., can solve the problems of uneven size of polysilicon grains, uncontrollable position of polysilicon grains, etc., and achieves large size and high performance. Uniform, performance-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

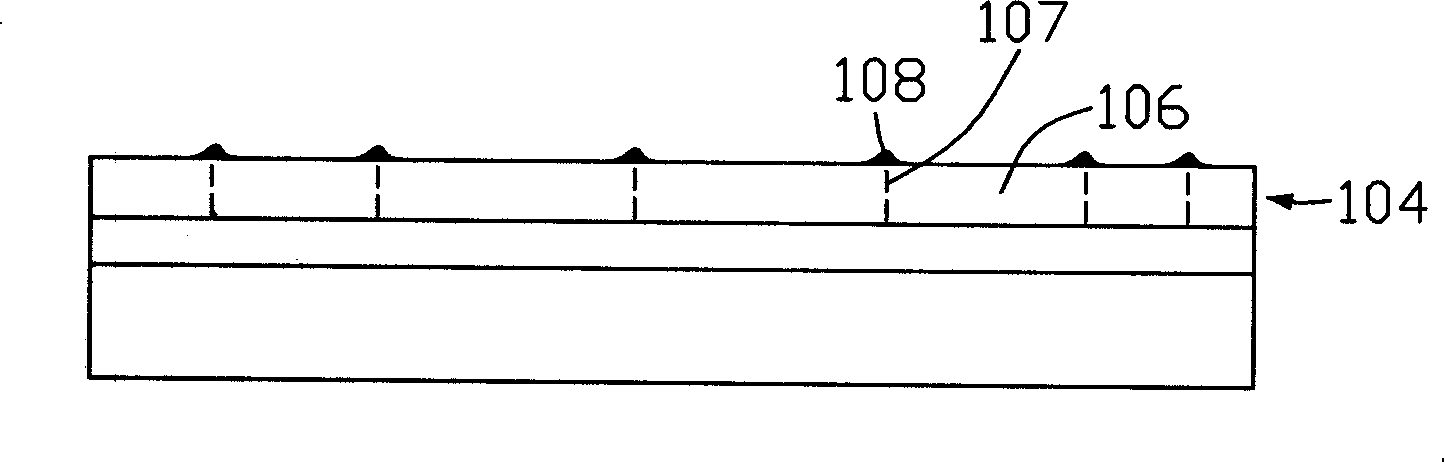

[0018] Please also refer to Figure 5 to Figure 11 , which is a schematic diagram corresponding to each step of a preferred embodiment of the method for manufacturing a low-temperature polysilicon thin film according to the present invention. The method for manufacturing a low-temperature polysilicon thin film mainly includes the following steps:

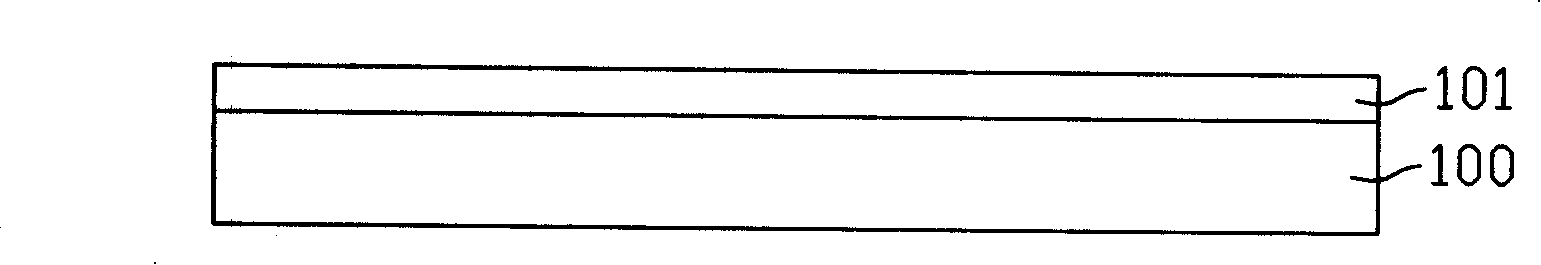

[0019] 1. Provide a substrate and form a buffer layer thereon;

[0020] see Figure 5 Firstly, a substrate 200 is provided, and the substrate 200 is a glass substrate or a plastic substrate. A buffer layer 201 is formed on the substrate 200, and the buffer layer 201 is a silicon nitride layer or a silicon oxide layer, and may also be a multi-layer structure including a silicon nitride layer and a silicon oxide layer. The buffer layer 201 is used to prevent substances in the substrate 200 from diffusing in subsequent processes and affecting the quality of the produced low temperature polysilicon thin film.

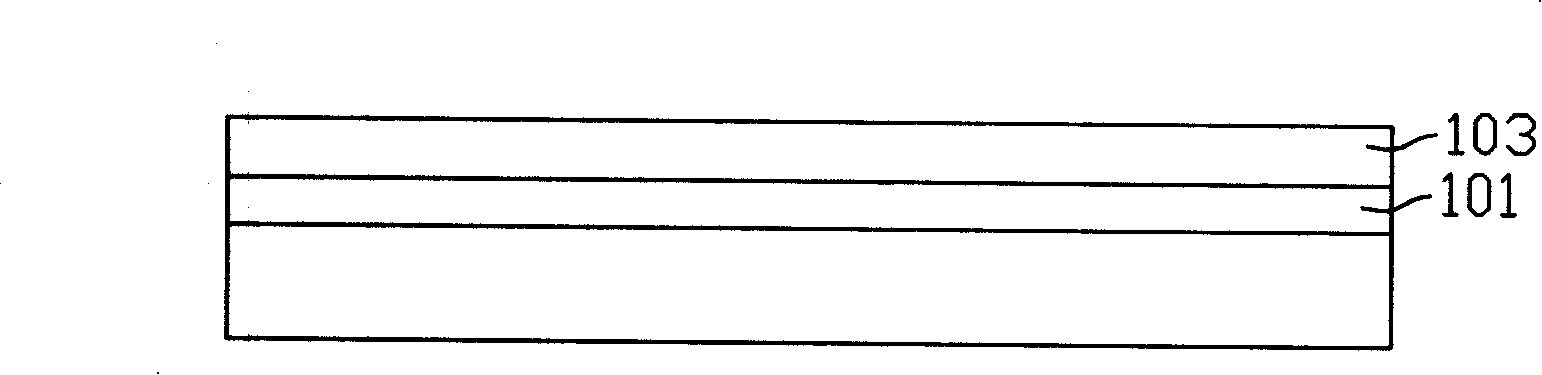

[0021] 2. Forming the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com