Preparation method for large-size dense barium titanate ceramic target material

A barium titanate and ceramic target technology, which is applied in the field of barium titanate ceramic target preparation, can solve the problem of low sample density and achieve the effect of short sintering time, single phase and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The preparation process of large size and dense barium titanate ceramic target is as follows:

[0021] 1) BaTiO 3 Powder and TiO 2 The powder is mixed at a molar ratio of 1:1, added with absolute ethanol and ball-milled to obtain the mixed raw material, dried and compressed with a tablet machine;

[0022] 2) putting the compressed tablet into an arc melting equipment to smelt under the protection of an argon atmosphere to obtain a block; then ball milling the block to obtain barium titanate powder with a particle size of less than 10 microns;

[0023] 3) Put the powder into a graphite mold and then move it into an FCT electric field activation sintering furnace, apply an axial pressure of 40-60MPa and raise the temperature to 1100°C at a rate of 95-105°C / min, and then increase the temperature at a rate of 8-12°C / min Raise the temperature to 1150°C, keep it warm for 20-30 minutes, lower the temperature, release the pressure and cool with the furnace, and finally get th...

Embodiment 1

[0029] Preparation of barium titanate ceramic target:

[0030] 1) The commercially available BaTiO 3 Micronized powder and commercially available TiO 2 Micropowder, weighed respectively at a molar ratio of 1:1, added absolute ethanol and ball milled and mixed for 2 hours to obtain mixed raw materials, dried the mixed raw materials, and pressed them into discs with a diameter of 10 mm and a thickness of 5 mm with a powder tablet press.

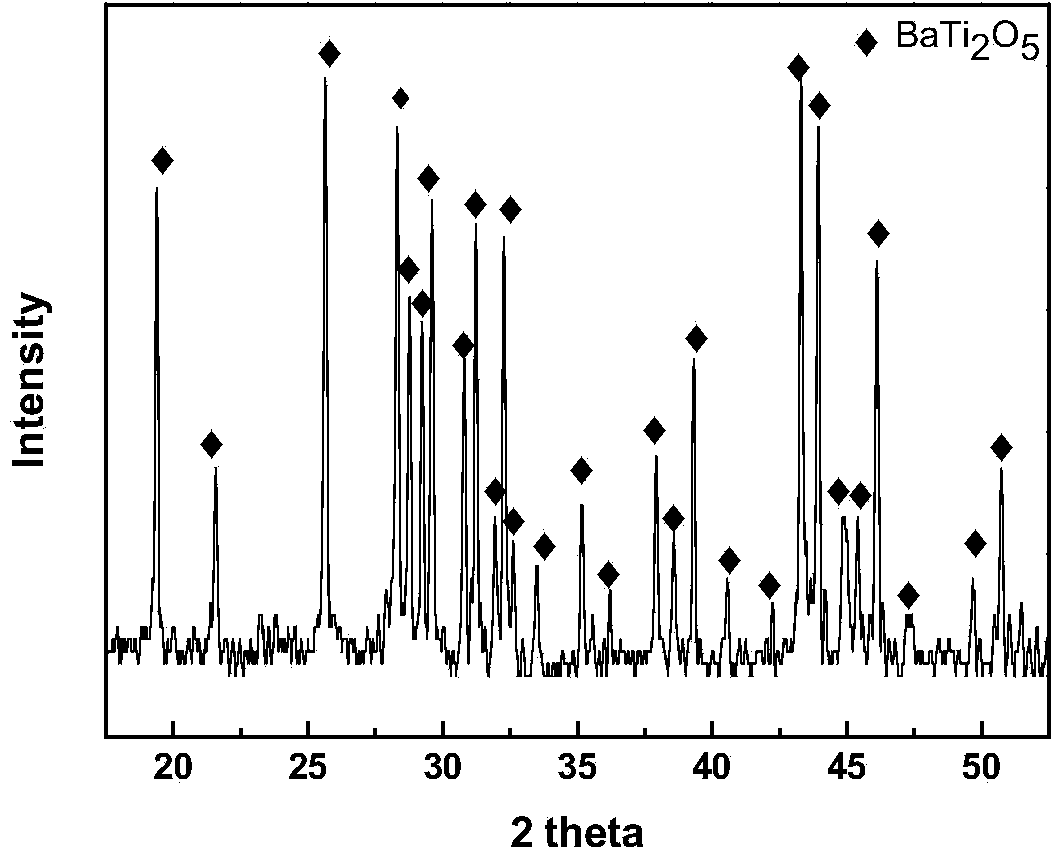

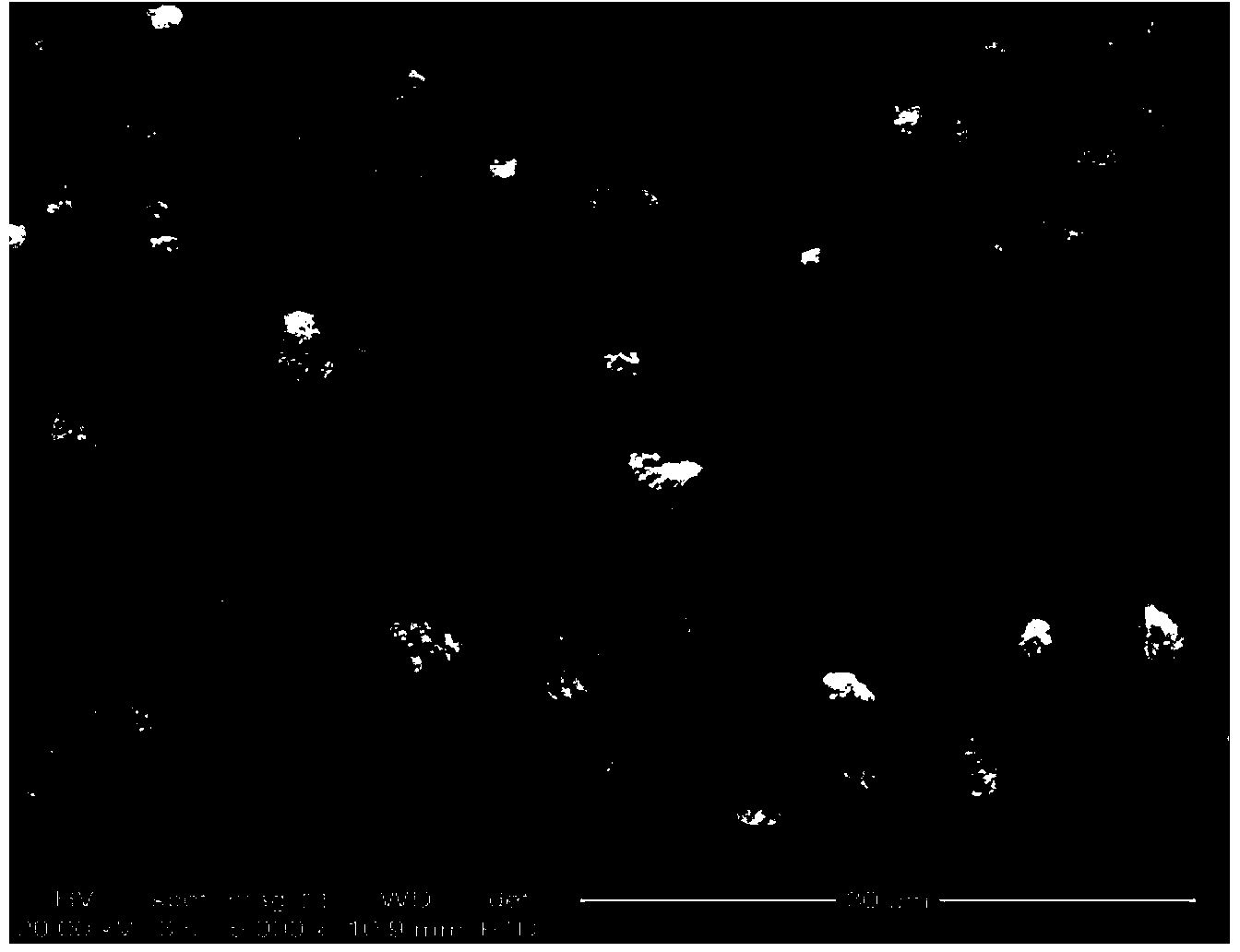

[0031] 2) Vacuum the arc melting equipment first, and then fill it with high-purity argon gas. After 5 times of repeated smelting, the synthesis reaction of barium titanate is fully carried out to obtain a block; the smelted block is broken, and then high-energy After ball milling for 10 hours, pure barium titanate powder with a particle size of less than ten microns was obtained. Gained powder XRD and SEM figure are respectively referred to attached figure 1 And attached figure 2 .

[0032] 3) Put the powder into a graphite mold with a d...

Embodiment 2

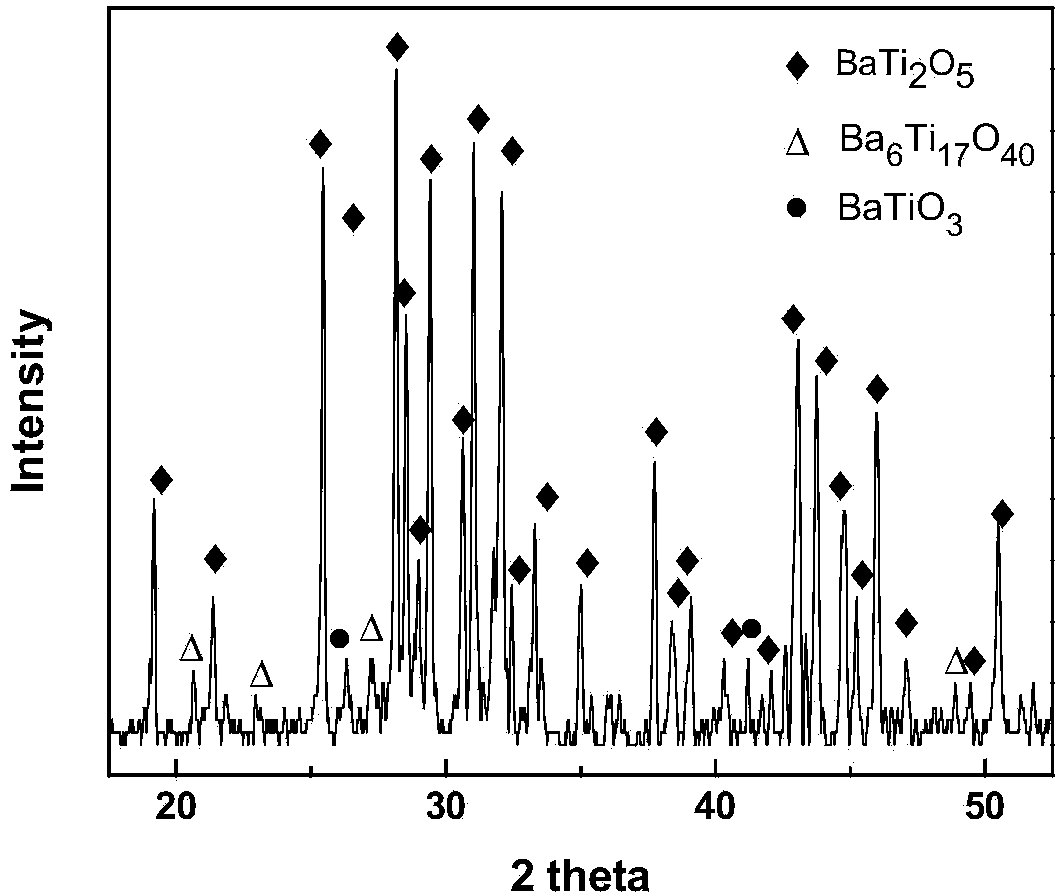

[0034] In Example 1, the sintering system was changed to: increase the temperature at a rate of 100°C / min to 1100°C, then increase the temperature at 10°C to 1150°C, and keep the temperature for 20 minutes. Apply a pressure of 40MPa. After reaching the holding time, start to drop the temperature, remove the pressure and cool down with the furnace. Compared with Example 1, the heating mode is changed, and the obtained phase is pure BaTi 2 o 5 , the density reaches 94.3%. The resulting product XRD figure refers to the attached Figure 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com