Fiber sintering type micro heat pipe and manufacturing method thereof

A manufacturing method and sintering technology, applied in the field of microelectronics, can solve the problems of heat pipe heat transfer performance decline, poor anti-gravity performance, complex processing technology, etc., and achieve good heat and mass transfer performance, high porosity, and simple processing technology Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

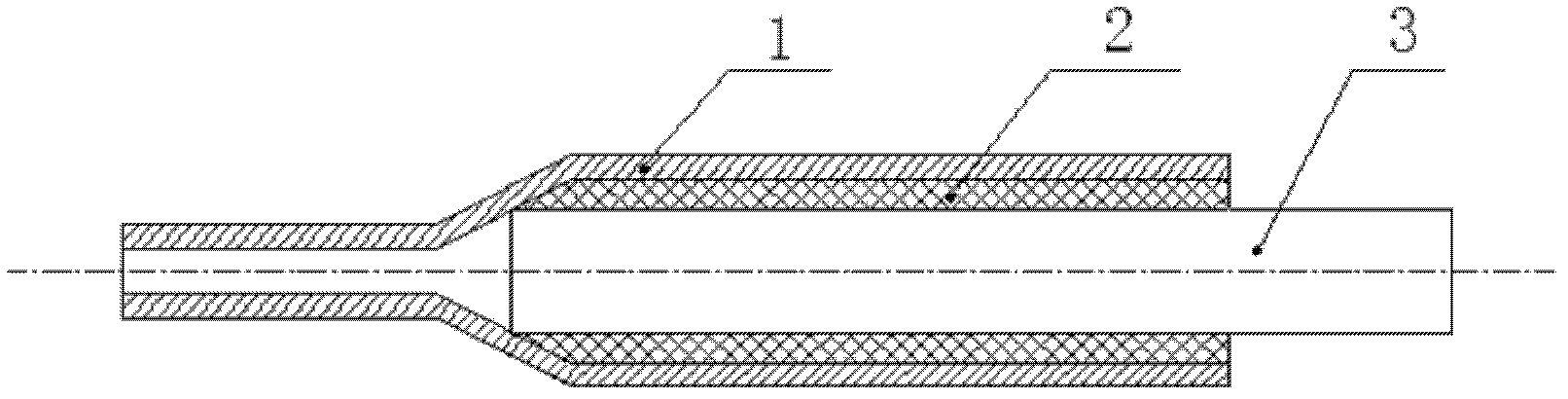

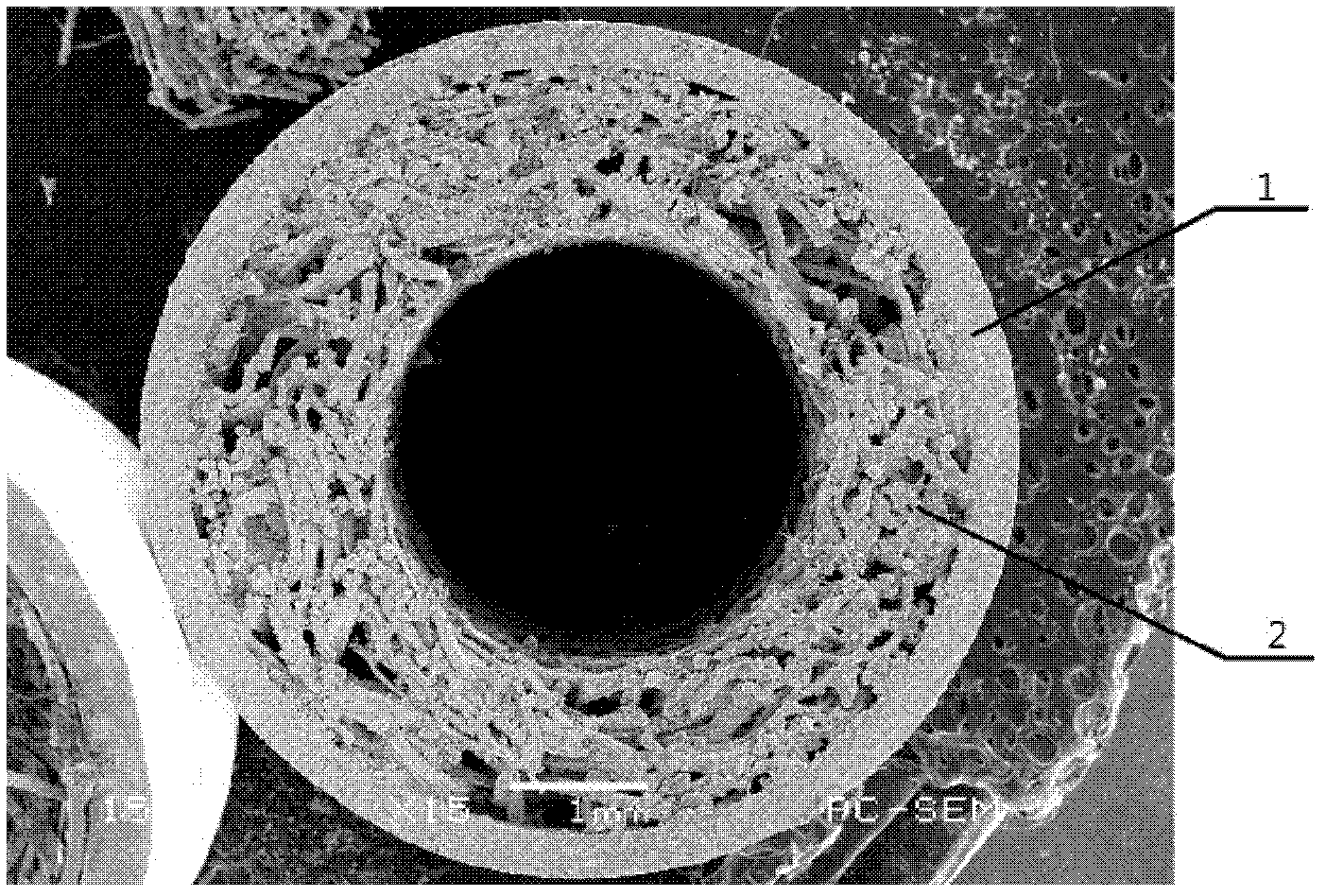

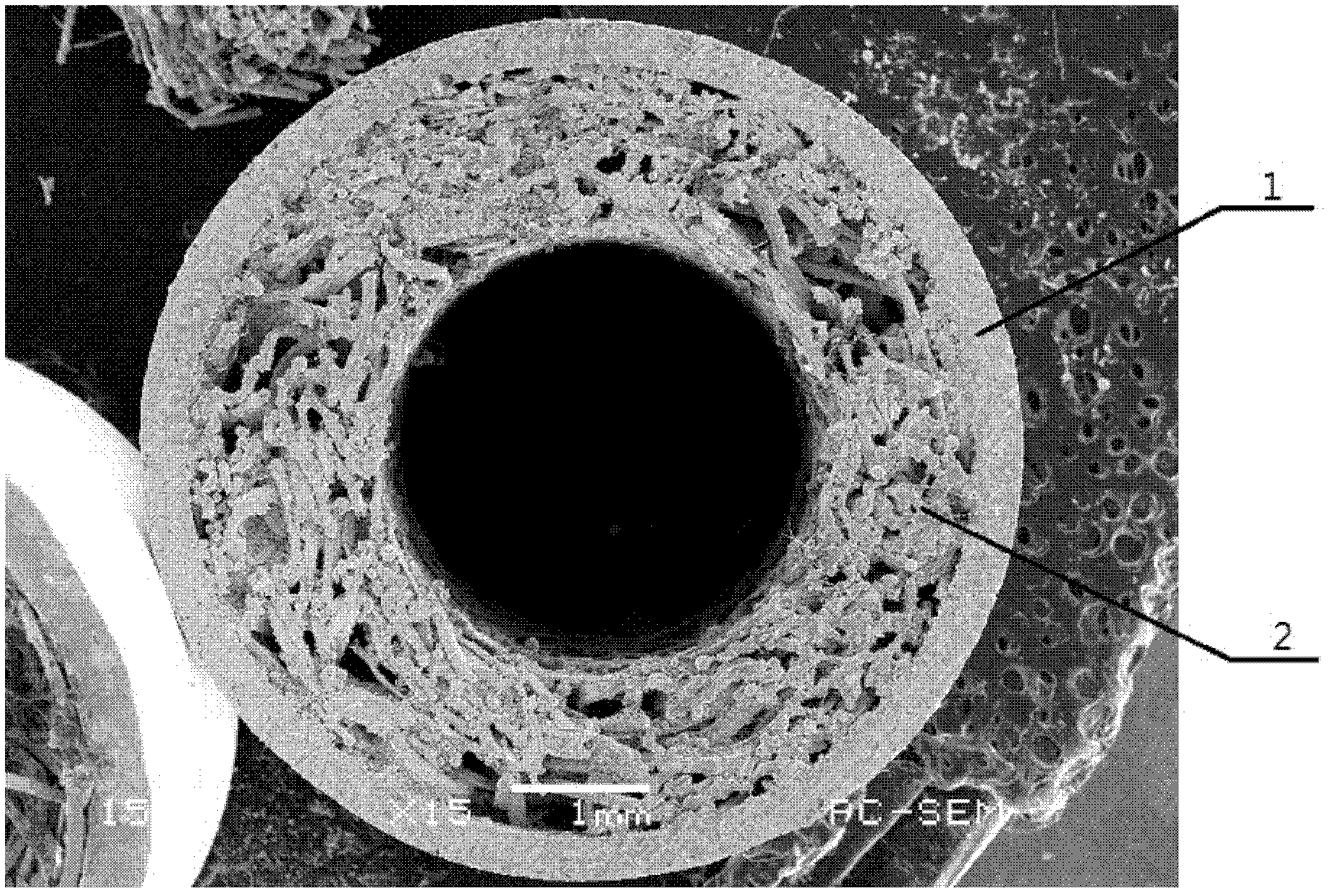

[0029] Such as figure 1 , figure 2 As shown, the fiber sintered micro heat pipe of the present invention comprises a base pipe 1, a liquid-absorbing core 2 and a liquid working medium filled in the liquid-absorbing core, the liquid working medium is any one of pure water, methanol, ethanol or acetone, and the base The inside of the tube 1 is evacuated, and both ends are closed structures. The base pipe 1 is a round metal pipe with an outer diameter of about 5 mm to 10 mm and a wall thickness of 0.2 mm to 0.5 mm. The liquid-absorbing core 2 is an annular metal fiber tube closely attached to the inner wall of the base pipe 1, the thickness of the liquid-absorbing core is about 0.3mm-0.5mm, and the porosity is about 65%-90%. The material used for the base pipe 1 can be red copper, aluminum alloy or stainless steel. The fiber used in the metal fiber tube can be copper fiber, aluminum fiber or stainless steel fiber.

[0030] The manufacturing method of the above-mentioned fibe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com